This one was a learning experience for me, and I hope my journey will help others if they run into this same scenario. A 2012 Nissan Quest with a 3.5L engine and the RE0F09B transmission came into our shop with the complaint that the CEL was on, there was a loss of power and the vehicle would not accelerate. After turning the vehicle off for a while, the concern had corrected itself and they were able to drive home.

I took the vehicle out for a road test to try to duplicate the concern. While I never experienced the lack of power concern (it sounded like a failsafe), I did get the van to shudder or chatter on acceleration from a stop. After getting it to act up a few times I was able to duplicate the issue with a level of consistency while generally at 20 to 40% throttle. Before I even got the van into the shop to complete the additional diagnostic steps, I was convinced that this Quest needed a CVT replacement.

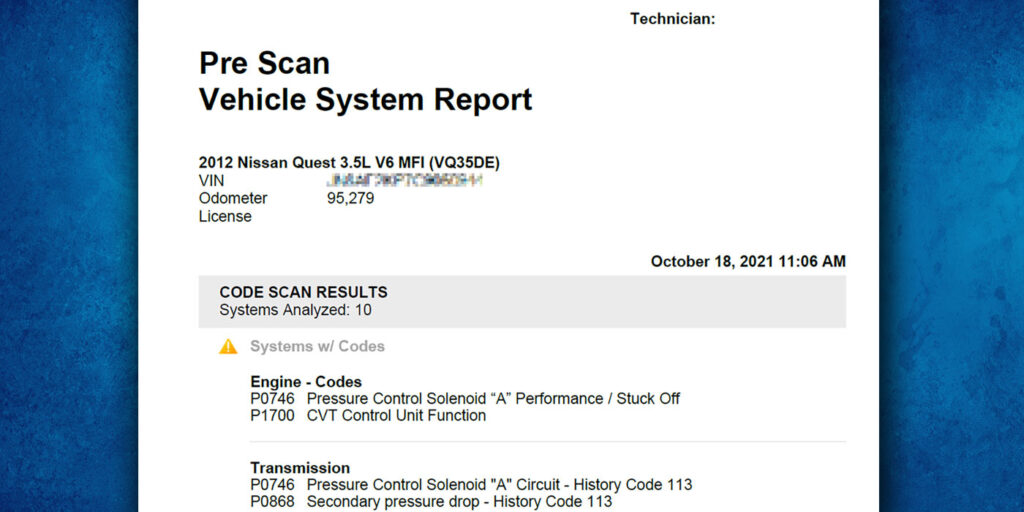

When I checked the fluid, it did not look too bad. There was some fluid discoloration, but not as bad as what I expected, and the level was correct. The battery and charging system analysis also proved to be good. A code scan resulted in P0746 (Pressure Control Solenoid “A” Circuit History Code 113) and P0868 (Secondary Pressure Drop History Code 113). There was also code P1700 (CVT Control Unit Function) appearing in the engine side of the module (as seen in Figure 1).

For those of you who have worked with these units before, you would know that this combination of codes usually results in an internal issue inside the CVT transmission. Since I am the lead diagnostician for Certified Transmission, I am not in the trenches day in and day out so I wanted to review service information for these codes.

- P0868: After all qualifiers are met, the “detected condition” must be the difference between secondary commanded pressure and actual pressure. The code sets if this difference exceeds .25 MPA (36 PSI) for 1.5 seconds at speeds of 9 MPH or less, or 2.0 MPA (290 PSI) at speeds over 9 MPH.

- P0746: The gear ratio of primary speed/secondary speed exceeds 2.7 for .2 second or exceeds 3.5 for .1 second. Holy smokes, that is a really short period of time!

Possible Causes: The only shared cause for these two codes is the “Line Pressure Control System.” Looking at the flow chart for both codes the only common denominator is to “Check Line Pressure.”

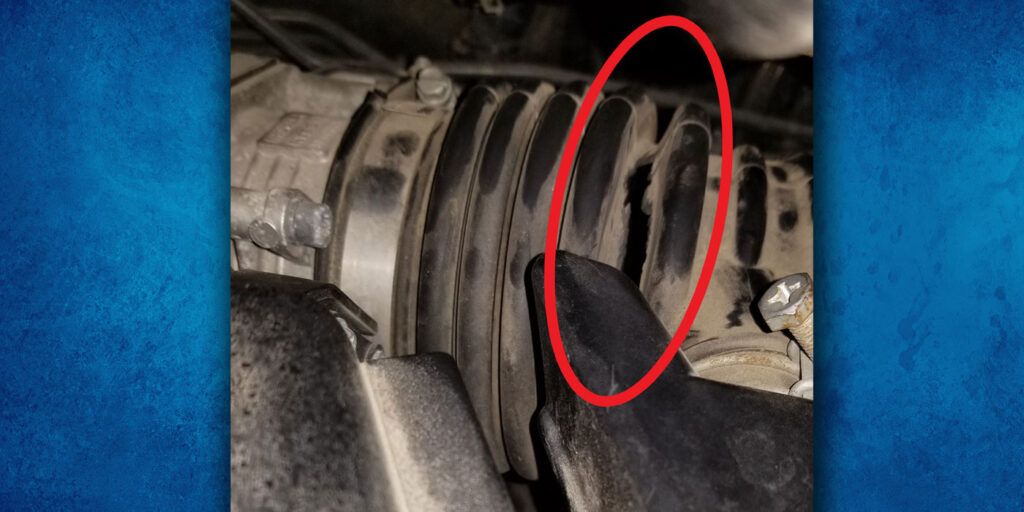

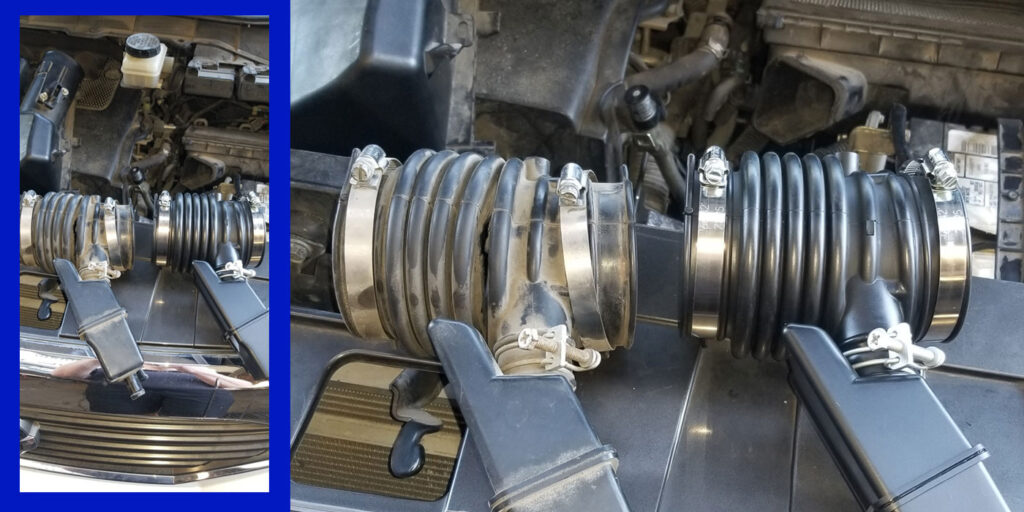

A word of caution: If you are ever told to check line pressure on a CVT Transmission, do not just hook up your pressure gauge that you have used forever; these things can run more than 800 PSI. I do have two Snap-On 5000 PSI pressure transducers so I can certainly check line pressure on this unit easily, but I was not convinced at this point that I needed to. I continued with the evaluation while I tried to decide if I was going to recommend a line pressure test before I condemned the unit. I checked all the normal items like cooler lines, CV boots and mounts as I was wrapping up, and as I began to shut the hood, I spotted something and went in for a closer look. I saw a split in the air intake tube. (Figure 2).

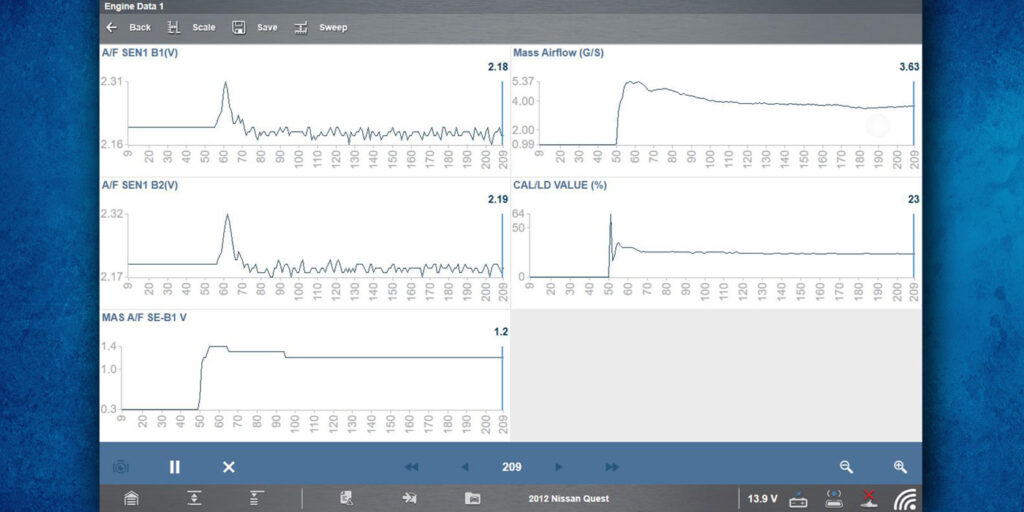

The engine seemed to run fine, and it never bogged or cut out. I had no MAF codes, no lean/rich O2 codes; basically nothing that would draw my attention to it. But there it was. With the scan tool still connected, I narrowed down the PID list to focus on MAF G/s, O2 A/F, and load (Figure 3).

I did not really see anything out of place; MAF G/s was at 3.63 so if you use the generic specs of liters vs. G/s at idle, 3.5L vs. 3.6G/s seemed normal to me. Full disclosure: I did not do a volumetric efficiency test although I probably should have. Thinking that the tube would have to be replaced regardless of how that test turned out, I decided not to do it.

As I was writing up my evaluation sheet with my recommendations and still going over everything in my head, I kept questioning if there was any way that this torn intake tube had anything to do with this issue. It couldn’t, right?

Read more stories in our R&R Tech series here.

I had been over the description and logic for both codes and nowhere in the documentation did it reference any type of engine-related load-sensing device. We have all been burned before by something not related to the transmission causing a failure; or at least, by thinking it is not related. I kept going back to the one possible cause for both codes as stated in the service information: “Line Pressure Control System.”

What if that was an over-generalized term and really covered anything related to the transmission or engine controls that could affect line pressure? A bad sensor reading certainly could fall into that category. Knowing that it would take a minimum of seven to 10 days to get a replacement unit built from our plant, I decided to tell the service writer that while I still thought that we were going to end up needing a remanufactured unit, I wanted to replace the intake tube and retest. The customer was informed of our plan and authorized the repair knowing that further repairs may be needed, and we ordered the new part from the dealer which was delivered the next day. (Figure 4).

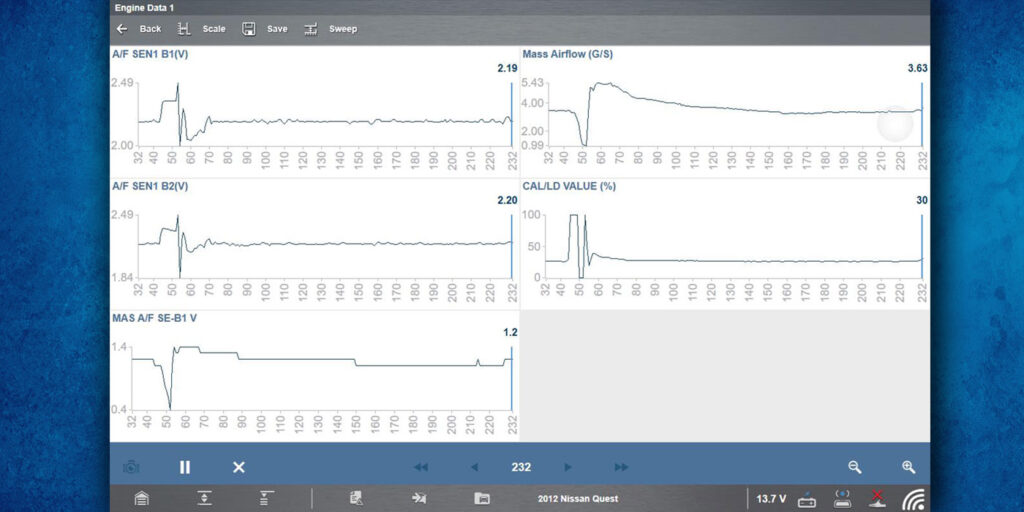

I installed the new intake tube and went back and looked at the same PIDS I’d reviewed before the replacement part was installed, and they nearly looked identical (Figure 5).

The calculated load was a little different this time, but the MAF G/s reading was the same. I headed out for another road test, but to my surprise I could not get the van to do anything wrong. I kept driving much longer than I did the first time I looked at it, and it was working great. I went back to the shop and had another tech go drive the van and he detected no issues. We even kept it another day and a couple more road tests and the vehicle never missed a beat. There were no codes setting and the vehicle was driving perfectly.

What exactly caused the codes to set in the first place is probably going to be speculative since one code is a pressure differential and one is a ratio error. Could the chatter have caused a speed sensor spike for .1 second and caused the P0746 to set? I could probably go for that, as it seems probable enough. The P0868 one is a little tougher for me to swallow since we are talking about commanded pressure and actual pressure for a minimum of 1.5 seconds. I’m not sure if the chatter lasted for a full 1.5 seconds, and if it did, could it really affect the pressure sensor reading? The only thing I can say for sure is that this vehicle is still currently working as designed. I waited three weeks after it left us to even start this article, and as it stands now, it has been almost four months since it left our shop.

Since the writing of this story we have seen these split intake boots on several Murano SUVs and Quest minivans with some units that we have been able to save, and others that have been driven too far to save. I really cannot prove this, but I do believe that the unmetered air entering the engine is affecting the load input to cause damage to the unit itself. It’s definitely a point to consider when diagnosing these vehicles.

Chris Adams started with Certified Transmission in 1986 as an R&R technician, and currently works as Lead Diagnostician. His current duties involve training and advising Certified’s retail diagnosticians, and assisting in research and development for the company’s remanufactured products. He also holds ASE Master and L1 certifications.