Shift Pointers

- Author: By Pete Luban, ATSG Technical Supervisor

Terminal Confusion Complicates Code Retrieval

There have been an increasing number of calls lately concerning manual code retrieval on Mitsubishi Montero models equipped with the R4A/V4A51 transmission.

The nature of the problem seems to involve the blowing of a fuse in the underhood fuse box when pin 1 of the OBD-II diagnostic connector is grounded.

When the PCM detects a fault in the transmission or its control system, the “N” lamp in the speedometer cluster (see Figure 1) will flash once per second. If the “N” lamp flashes twice per second, this is indicating higher-than-normal transmission-fluid temperature.

Figure 2 shows the location of the OBD-II connector in these vehicles. It’s right next to the white Mitsubishi connector under the dash, just to the right of the steering column.

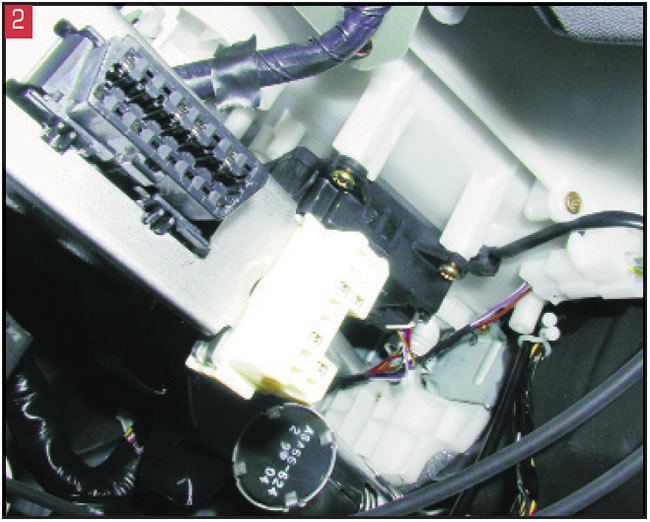

All printed information instructs the technician to insert a jumper wire into the OBD-II diagnostic connector at terminal 1 and ground it. At this time the “N” lamp will flash a code pattern in a typical two-digit code-display format: long flashes followed by short flashes.

A close look at the OBD-II diagnostic connector in Figure 3 reveals the number 1 molded into the plastic right next to the serial data wire at terminal 1 of the diagnostic connector. (Note: This is the terminal that should be grounded!)

The number 1 also appears next to terminal 16 of the diagnostic connector, but because the connector narrows at that location, the number 6 is cut off and terminal 16 can be mistaken for the real DCL terminal 1 (see Figure 3).

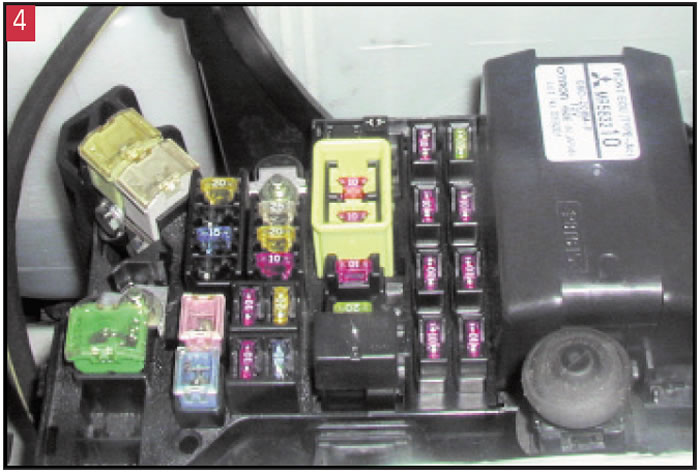

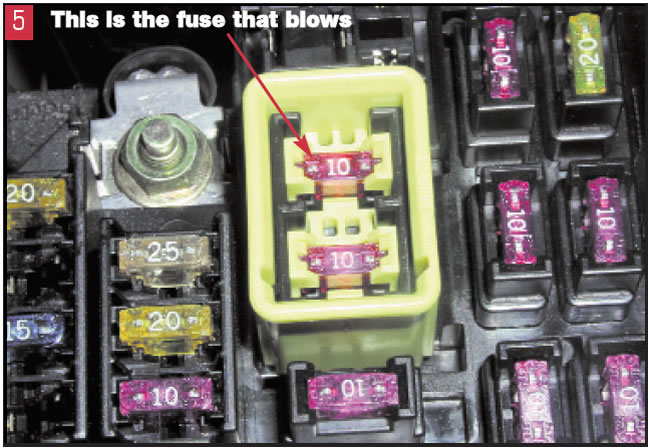

Now, let’s get to the blown fuse. The power supply for the DCL that powers a scan tool, and blows when accidentally grounded, is the 10-amp dedicated fuse #5 in the underhood fuse box (see figures 4 and 5). This fuse powers most of the interior lighting, the radio and terminal 16 of the diagnostic connector.

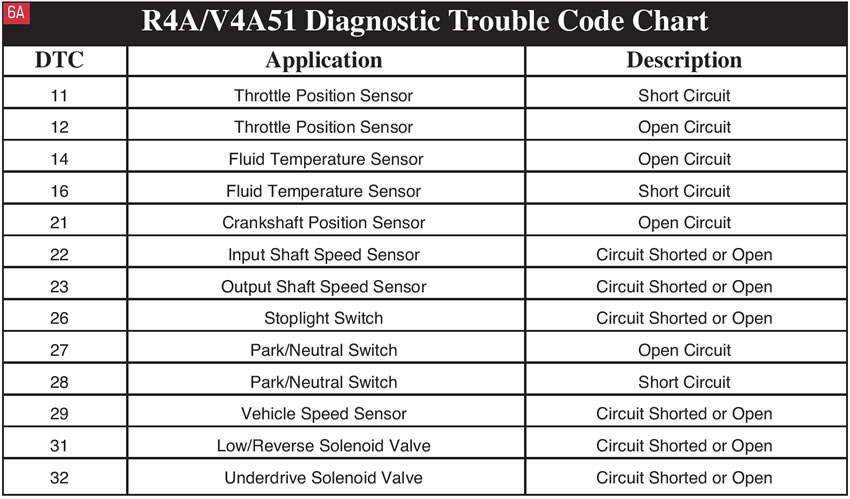

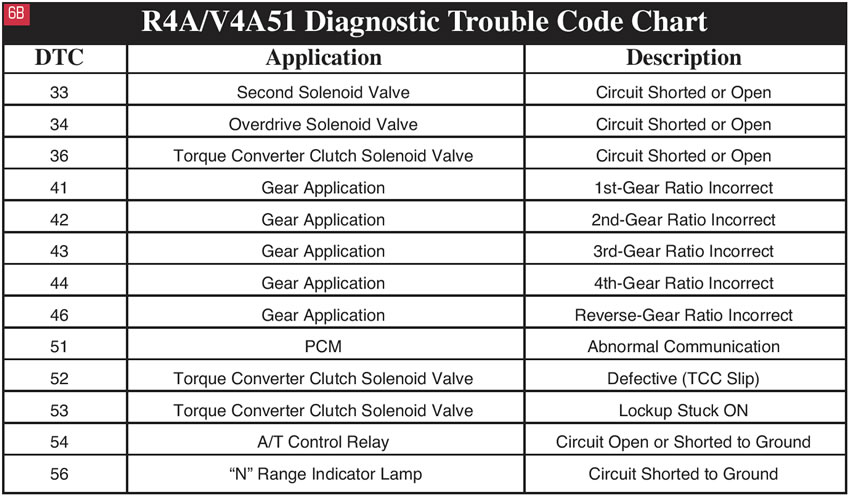

Figure 6 is a chart identifying the two-digit trouble codes, which are more reliable than OBD-II “P” codes, and that’s true for any Mitsubishi vehicle.

To clear codes, disconnect the negative battery cable for at least 10 seconds. Then reconnect the cable and turn the ignition on to ensure that all codes have been cleared. Next, make certain the vehicle is at normal operating temperature and let the engine idle for about 10 minutes to let the PCM complete its adaptive learning memory. Road test to let the PCM fine-tune itself, and that’s it.