Hybrids are coming to our shops, like it or not. I seem to be getting a lot more customers lately who are asking questions about hybrids. They want to know things like: “How far can you go on one before you have to plug it in and recharge?” “How dangerous are they?” “What happens if you run into a flash flood or get into an accident?” “Could you get shocked getting out of the car?” and “How long does that $10,000 battery last?” There are a lot of technicians out there who have some pretty strange ideas about hybrids also.

I ask technicians on a pretty regular basis what they do when they get a hybrid in their shop. A large portion of them are afraid to touch them. Many of them have been to hybrid training classes that emphasize the dangers and high-voltage precautions to the point that they figure the risk isn’t worth the return.

There seem to be some common misperceptions among technicians and customers alike about hybrids. The biggest one is the question about the danger of getting shocked. When a hybrid (Toyota’s, anyway) gets involved in an accident, there are crash sensors that detect an impact and shut down the high-voltage system so that no high voltage is present in the vehicle outside of the battery box.

The high-voltage system is also shut down if the restraint system detects a collision. Also, as soon as the car is switched off, the high-voltage system is turned off. Even when the car is running, there are no exposed circuits you could touch and get shocked. The circuits for the motor generators that need to be accessed to, say, remove the inverter are not live voltage as soon as the cover of the inverter is removed – even if the system were left running.

The myths about people getting electrocuted from working on, towing or somehow accidentally touching a high-voltage circuit are false. The redundant safety features surrounding the hybrid vehicles are well thought out and do an excellent job of making sure a technician cannot get hurt from the high-voltage part of the hybrid system during any normal operation or maintenance service.

The biggest problems I encounter are caused by the simplest mistakes, such as setting codes and turning a running vehicle into a tow job simply by adding too much oil. By “too much,” I’m saying you can run into trouble on – say, a Generation 1 Prius – by changing the oil and putting in four quarts instead of the required 3.9 quarts of oil.

I have had more than a few of these vehicles show up at my shop (some towed in) with symptoms like a dead HV battery, no-start or low-power codes, a diagnosis from the dealer of a bad HV battery due to being cranked too low, a bad inverter due to codes related to inverter overheat. These kinds of problems are all too common on these cars and more often than not get misdiagnosed by well-meaning technicians. I know how easily this can happen because I’ve made pretty much all the mistakes one can make working on my own hybrid vehicles.

Experience is definitely the best teacher on these vehicles, and necessity is the mother of invention. Knowing is half the battle. For example, a Generation 1 Prius gets towed to your shop with codes P3191 and P3101, and an engine that won’t crank because of a dead HV battery. This is a realistic scenario that you could easily find yourself in the middle of if you choose to work on hybrid vehicles.

The dilemma you find yourself faced with is, No. 1: How do you deal with the dead-battery issue? Do you buy a new HV battery, try to figure out how to charge the existing battery, get a good used one and then try to diagnose the other problems?

Whenever possible, I like to substitute a known-good HV battery. This allows me to charge the owner’s HV battery while I diagnose the other problems.

Problem No. 2 is that these codes can be tricky to trace, since it’s difficult to tell the difference between a cranking and a running gas engine on these cars because the cranking speed is nearly 1,100 rpm – compared with a non-hybrid vehicle that cranks at less than 400 rpm. In a normal cranking situation on a hybrid, the gas engine spins at 1,100 rpm for a few seconds, then shuts back off after replenishing the energy used during cranking. This sounds strikingly similar to the engine cranking, producing no power, and the HV controller stopping the cranking once it determines that the gas engine is not producing power.

Depending on the condition of the HV battery, you have a limited number of cranks without starting before the HV battery drops below 20% state of charge and won’t allow cranking anymore.

The problem now becomes: How do you determine the difference between cranking and dying vs. cranking and shutting off normally before you deplete the HV battery? I have found that, for me, the best way to make that determination is by looking at the current from the HV battery using a current probe and lab scope.

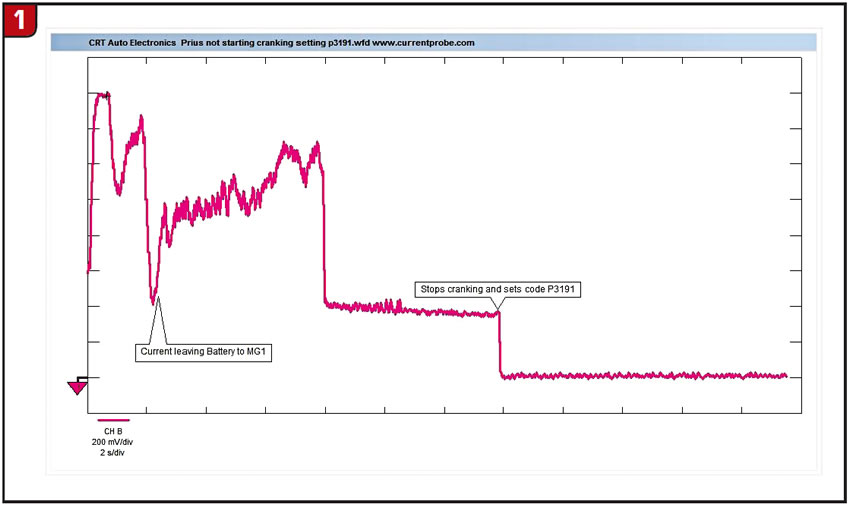

The waveform image in Figure 1 shows the current is leaving the battery and cranking the gas engine until setting Code P3191.

You can see that the engine didn’t start because the current never drops below the zero line. This is due to the direction I have the current probe clamped on one of the DC cables leading to the inverter from the HV battery. If the engine were running and producing power, the current would go below the zero line as long as charging is taking place.

The problem here is how to determine the cause of the no-start without having to crank the engine too many times and running the HV battery low.

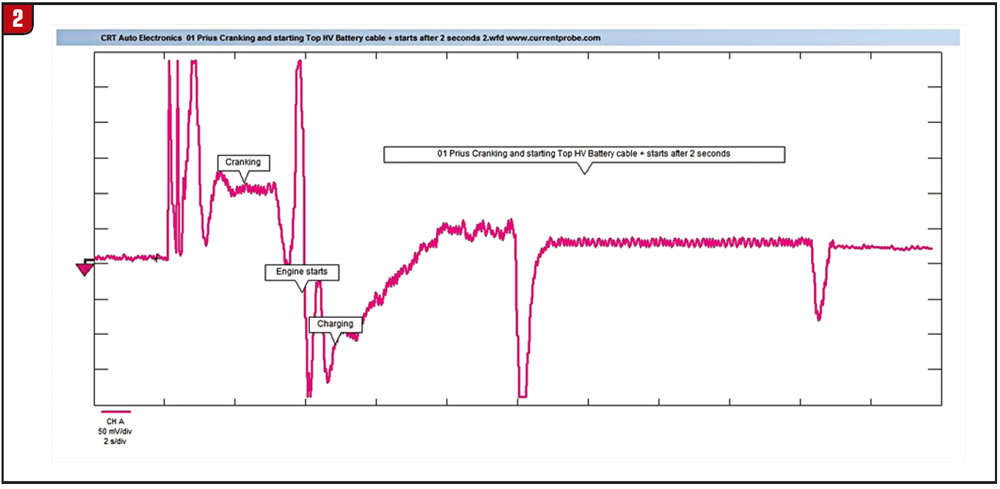

In Figure 2 you can see that the current drops below the zero line after four seconds of cranking.

Note that the zero-current line is four divisions up on the scope screen. Current above that line is leaving the HV battery and being used by Motor Generator 1 to crank the gas engine. Once the gas engine starts producing power (after four seconds of cranking), the current drops to the lower side of the zero-current line as the current goes back into the battery.

This is a normal start-stop cycle and completes in about 10 seconds. I can’t tell – by listening alone – the difference between the start and stop during a normal cycle and the crank and stop when the code sets. This technique also allows me to detect problems with the gas engine, such as hard starting due to problems like worn ignition components or something as simple as an overfull crankcase or dirty MAF sensor – two of the most-common reasons for setting the codes.

The issue of dealing with the dead HV battery can be easily overcome when one understands that the HV battery is made up of individual 7.2-volt cells that can be charged either individually or in groups, as long as a proper voltage source is used to charge them. Having a spare charged battery has helped a bunch with dealing with these cars, especially when they reach the shop with a dead HV battery and a no-start gas engine. Hopefully, this tip can save some of you techs from going through some of the same problems we did on the early ones.

The fun continues!

Jeff Bach is the owner of CRT Auto Electronics in Batavia, Ohio. You can reach him at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.