TASC Force Tips

- Author: Ed Lee

When a technician is disassembling a Mercedes 722.3 transmission and finds a damaged stator support, most of the time it’s not a big deal. A replacement stator support usually is available for $125 or less, and most often it doesn’t take more than a day or two to get the part. However, situations do arise from time to time that may call for more-drastic measures. These situations usually occur on Fridays and sometimes are complicated by the fact that the vehicle you are working on belongs to a close friend or relative. (Your own wife or her boss is an even-worse scenario.)

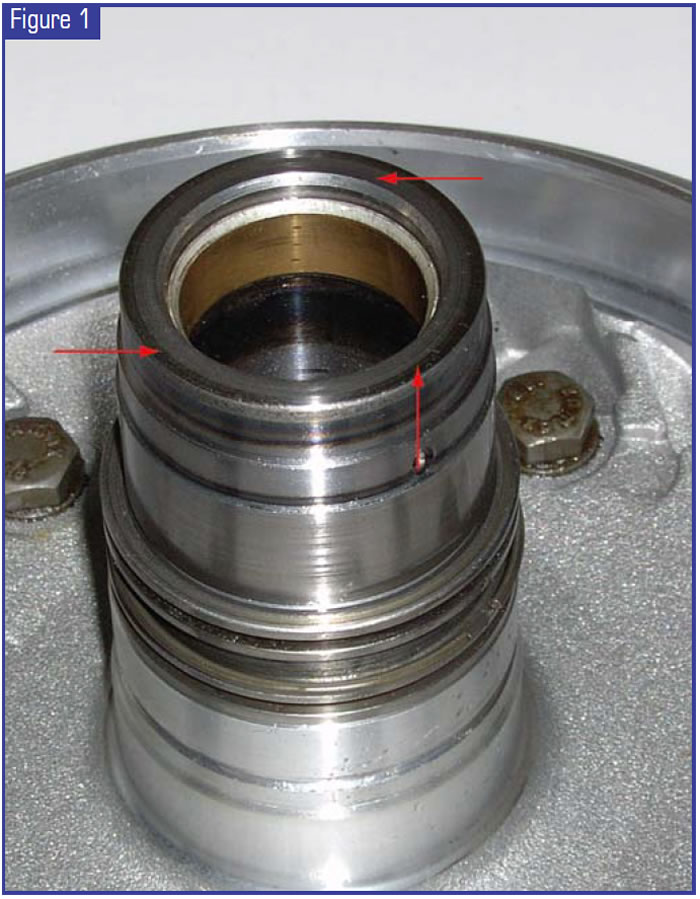

What happens is this: You’re assembling the 722.3 transmission and find that spalling has occurred on the bearing surface at the rear of the support (see Figure 1). The pitted area, caused by the spalling, was missed during disassembly and cleanup, and now it’s your problem.

In dealing with this problem there are two important factors that you have to keep in mind. One is that the surface you are dealing with is also a race for a bearing. Since a bearing race has to be at least about 60 Rockwell in hardness, your new surface also will have to be that hard. Your second consideration is about how critical the endplay is on this transmission. There are selective shims that go between the bearing race and the K1 drum to adjust endplay, but the combined height of the race and shims cannot exceed the height of the K1-drum centering sleeve. The sleeve provides location for the shim and bearing. For this reason and because the endplay adjustment is critical, the stator support must be as close to OE height as possible.

There’s a quick and easy alternative that will meet both of these needs. Get a CD4E No. 4 turbine-shaft thrust-bearing assembly. Separate the race from the bearing with your pocket screwdriver (see Figure 2). You will find that the bearing race is about 0.040 inch thick. Chuck the stator in a lathe and remove 0.040 inch of material from the back of the stator, and put a chamfer on the inside diameter so that the bearing race will sit flat.

Most of the dimensions of the race will require no modifications, but you will have to remove a small amount of material from the part of the bearing race that fits down into the I.D. of the stator support (see Figure 3). Remove enough of the material to provide clearance between the bearing race and the bushing in the stator support. This process can be done on a bench grinder, because it is only for clearance and does not have to be perfect. Your finished product will look like Figure 4.

Ed Lee is a Sonnax Technical Specialist and a member of the TASC Force™ (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.