Up to Standards

- Subject: Operating theory of manual transmissions

- Unit: Tremec T5

- Vehicle Applications: Ford Mustang

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

The key to successfully diagnosing and repairing a complex assembly such as a modern automobile can be achieved only by understanding how each component works and its relationship with other components. Too often we see technicians struggle with a problem only to find that the problem is external to the transmission.

On automatic transmissions, engine-related computer problems can affect transmission operation. Computer-controlled vehicles have very complex electronic circuits and multiple computers, all of which need to work together. That being the case, we will start with the basics of rear-wheel-drive manual-transmission function and proceed to more-complex diagnostic issues with transfer cases and front-wheel-drive manual transmissions in the next series of articles. Transmission designs may vary in size, shape and appearance, but all the units function in the same manner.

By definition a transmission transmits power from the engine to the driving wheels. It does not make power, but it makes the power usable by dividing it into a series of steps. The engine torque is made usable by the ability of the transmission to create mechanical advantage and apply it in a manner that keeps the engine in the power band for smooth operation and maximum fuel economy.

The transmission is equipped with different gears, each having a ratio to create optimal power flow from the engine to the final drive of the vehicle. Vehicles with engines having a narrow power band, such as a diesel in an over-the-road semi-trailer, will have multiple gears. Diesels have a very narrow power band, usually from 1,200 to 3,500 rpm, and need multiple gearing of 10 to 16 speeds, which causes the driver to make frequent shifts as the engine reaches the top of its speed range and the limit of its pulling ability.

Car and light-truck transmissions are similar, but with fewer speeds necessary because of the much broader power band of gasoline engines. Obviously, first gear will be the lowest gear, or highest ratio, providing the most mechanical advantage. It takes about 150 horsepower to break the average full-size car away from a dead stop cleanly but only 15-30 horsepower to maintain a 60mph cruise speed on flat ground.

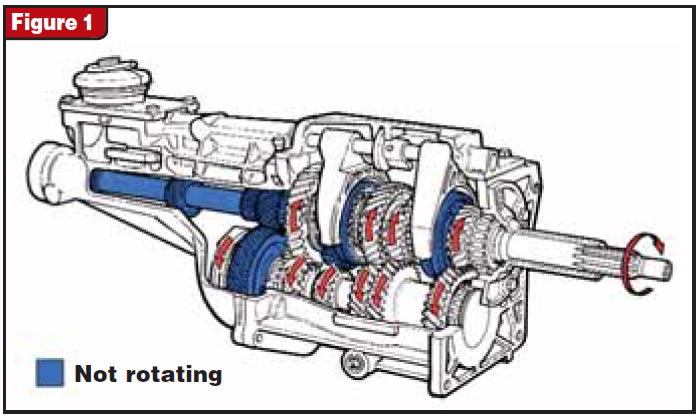

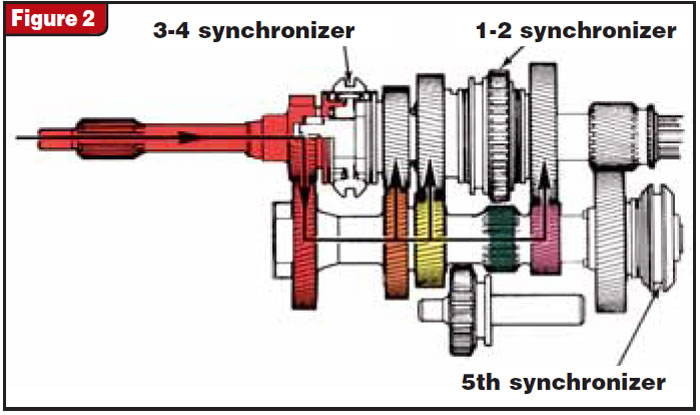

All forward gears on a manual transmission are in constant mesh. This means that if the input shaft is turning, it will turn the countershaft, as they are in constant mesh. If the countershaft is turning from power through the input, the opposing speed gears on the mainshaft (output shaft) also will be turning, as they are in mesh with the gears on the countershaft. The input shaft can turn freely with the counter gear (cluster gear) in neutral while the output shaft does not move with the vehicle stopped. This is how engine power is disconnected from the output shaft to provide a neutral condition (see figures 1 and 2).

Understanding the power flow through the transmission is the first step to a diagnosis by using operational theory. You must understand what is “on” in each gear to begin problem solving. At speed, when the driver disengages the clutch to make a shift, the rear wheels are driving the mainshaft at road speed while the input shaft is turning at idle or a lower speed than the mainshaft (output shaft).

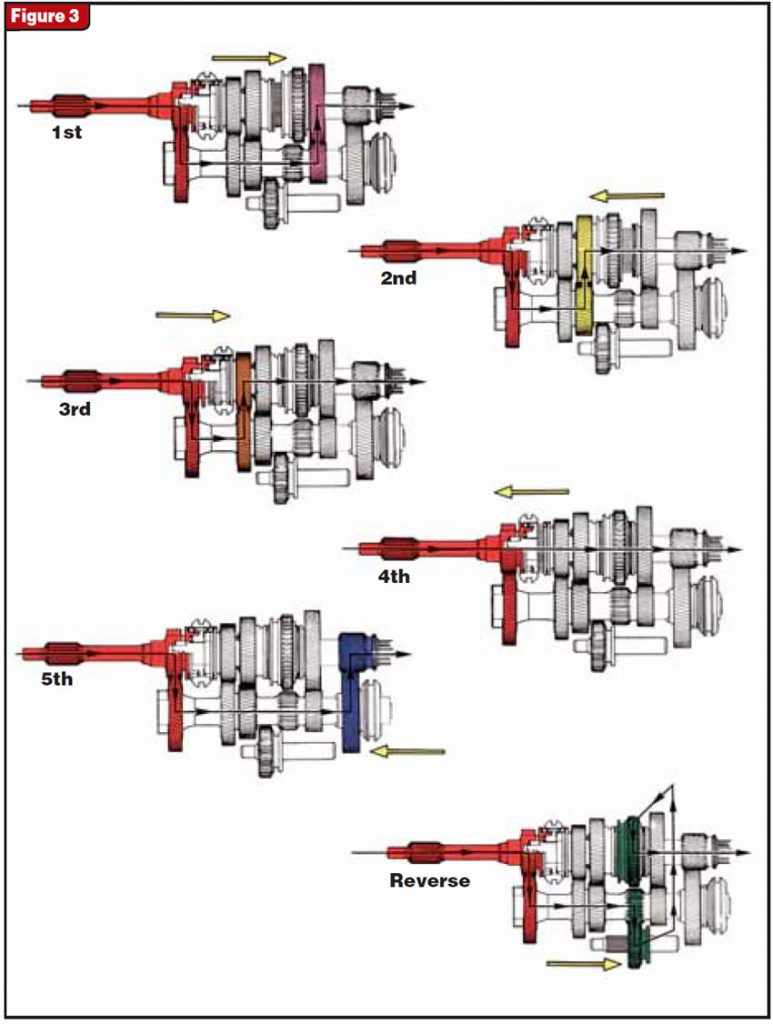

To achieve a shift it is necessary to lock the mainshaft speed gear selected, which is freewheeling to the mainshaft. The synchronizer body or hub is splined to the mainshaft. To select a gear, the driver moves the shift lever, which through the shift fork moves the sliding sleeve of the synchronizer to engage the coupling teeth on the speed gear. Once the teeth are engaged, the speed gear is now locked to the mainshaft while the other speed gears freewheel in mesh with the countershaft, and the ratio of the gear selected gives the engine the mechanical advantage to operate smoothly and efficiently (see Figure 3).

When the engine reaches the limit of the power band or torque curve, the driver selects another gear. With few exceptions fourth gear is usually direct drive, in which the mainshaft is locked to the input and we have a 1-1 ratio; the counter gear is still turning because of constant mesh with the input, but there is no power flow through the counter gear. There are a few transmissions in which fifth gear is direct drive and sixth is overdrive.

The next step to understanding power flow is through ratios and the difference between input- and output-shaft speeds. We’re using a typical rear-wheel-drive five-speed transmission to look at the power flow on the attached chart. The Tremec T5 transmission for a Ford Mustang in this illustration has the following ratios:

- 2.95-1, 1st

- 1.94-1, 2nd

- 1.34-1, 3rd

- 1-1, 4th

- 0.68-1, 5th (overdrive).

You will notice that the first-gear ratio is not that low, because this unit is meant for use with a 302-cubic-inch V-8 engine, which has enough torque so that a very low (numerically high) first-gear ratio is not necessary. A unit for a V-6 engine might have a 3.36-1 1st gear, and a four-cylinder engine would require an even higher number (lower ratio) to make up for its lower torque rating.

This is also why identifying which unit you are working on is absolutely necessary. We have seen many instances in which a customer with a V-8 bought a “similar-looking” unit from a salvage yard, only to have poor drivability and a failure within a few weeks. Putting a transmission designed for a four-cylinder behind a more-powerful engine is a recipe for instant disaster.

Looking at the power flow in 1st gear with a ratio of 2.95-1, we see that power flows through the input into the cluster and then to the 1st-speed gear. With this ratio we will have 2.95 turns of the mainshaft for every turn of the input, which is almost 3 to 1. This is easy to see when you’re driving, as the engine will turn three times as fast as the output shaft and you will reach maximum engine speed at a low road speed, with a maximum pulling power at the wheels.

In 2nd gear, with a 1.95-1 ratio, the engine will turn almost twice to get one revolution of the mainshaft. In 3rd gear, with a 1.43-1 ratio, the crankshaft will turn 11/3 times to get one turn of the output shaft. In 4th gear we get direct drive, with one turn of the crankshaft giving us one turn of the mainshaft.

In 5th gear, which is overdriven, we get about 5/8 turn of the crankshaft for a full turn of the output shaft. You can see how this is a cruising gear, maximizing fuel economy with low engine revolutions for efficient highway cruising. When you come to a hill in 5th, though, it will be necessary to shift to a lower gear to put some mechanical advantage back into the driveline to maintain highway speed without lugging the engine. Note: We have looked at only transmission ratios here, and those need to be multiplied by the drive-axle ratio to get the overall final-drive ratio.

Figuring out ratios helps you to be able to identify which transmission you are working on. Many times you will be asked to repair a unit that has been previously repaired and that has no ID tag. Your gear supplier will ask you for tooth counts to make sure it is giving you the correct parts for your application. The T5 we are using for our example has 261 design levels, most of which have different ratios depending on application.

To determine ratios you need to do some simple math. Starting with the input shaft, divide the number of helical teeth on the input into the number of helical teeth on the mating gear on the countershaft. This will be your input ratio; put it aside for future use.

Now go to 1st gear and divide the number of teeth in the larger counter gear by the number of teeth on the 1st-speed gear on the mainshaft. Multiply your answer by the input ratio and you now have your 1st-gear ratio. To find the overall ratio for 1st gear multiply the 2.95-1 1st gear by the final-drive ratio. Using a 4.10-1 drive-axle ratio as an example, you have 2.95 X 4.10 = 12.09 overall ratio, which should give you tire-spinning mechanical advantage.

Do the same thing with the 2nd and 3rd gears. 4th gear is direct drive, so your overall ratio would be 4.10 with mechanical advantage coming from the ring and pinion.

Overdrive gear presents a slightly different approach. The overdrive gear is mounted on the countershaft with the speed gear on the mainshaft. Divide the large number on the countershaft into the smaller 5th driven gear, and multiply the answer by the input ratio you previously determined. This will result in a much lower ratio, which is overdrive.

If you know your theory and what is working inside the transmission in any gear, problems become easier to solve. Knowing your ratios will help you obtain the correct parts if a tag is missing or unreadable and to make sure that the transmission the customer brought to you is correct for the application intended. This precludes unnecessary warranty issues and lost time.

Here’s an example of troubleshooting by theory: A five-speed transmission in a pickup truck comes your way with a customer complaining of noise while driving. You road-test the vehicle and find that all gears except for fourth are noisy in operation. The noise relates to increased engine speed, getting louder as the engine revs up. Fourth gear, however, is much quieter.

If you understand that in fourth gear no power is flowing through the countershaft, attributing the noise to failed countershaft bearings is a fair conclusion. A bearing noise will increase with rotating speed, and since there is little or no thrust load on the countershaft in fourth, there is much less noise in that gear as there is very little load on the countershaft bearings.

In the next article we will look at more-advanced theory, including shift problems and synchronization, and follow that up with common electrical and mechanical diagnoses for electronic and other types of transfer cases. Knowledge equals confidence to solve problems and make good decisions. Most problems aren’t that hard; we just make them hard through ignorance or learning while we go, which is expensive.