Up To Standards

- Author: Mike Weinberg, Contributing Editor

The press and various economists have been kind enough to let us know that this country is in a recession. Our industry has known this fact for at least a year, and very few of our people have advanced education degrees. While all these geniuses were hyping stocks like Enron and Global Crossing, we grunts were in the trenches dealing with real people who have real problems, not the least of which is less money in their pockets. This makes it imperative for us to maximize our profit from every job and to do it right the first time.

If you are in the transmission-repair business, you will work on a percentage of stick transmissions. This will inevitably lead to replacing worn-out or damaged clutches, since a large percentage of transmission damage starts with a worn or improperly adjusted clutch. There is good money to be made in clutch repair, and any time you remove a stick transmission, make sure you remove and inspect the clutch. This is added value for your customer, because he already is spending money on labor to R & R the transmission, and you are doing a thorough job by inspecting and replacing a marginal or damaged clutch assembly while you protect yourself during the warranty period on the repairs you make to the unit. Remember that of all the components in the powertrain, the clutch and manual transmission are most at the mercy of the skill of the driver.

There are four major OEM clutch manufacturers. Daikin Clutch is OEM on every Japanese vehicle and on many American vehicles. LuK is a major OEM manufacturer in the U.S. market. Valeo also has a large OEM presence, and Sachs is OEM to the European carmakers. All of these manufacturers market clutch-replacement sets to the aftermarket.

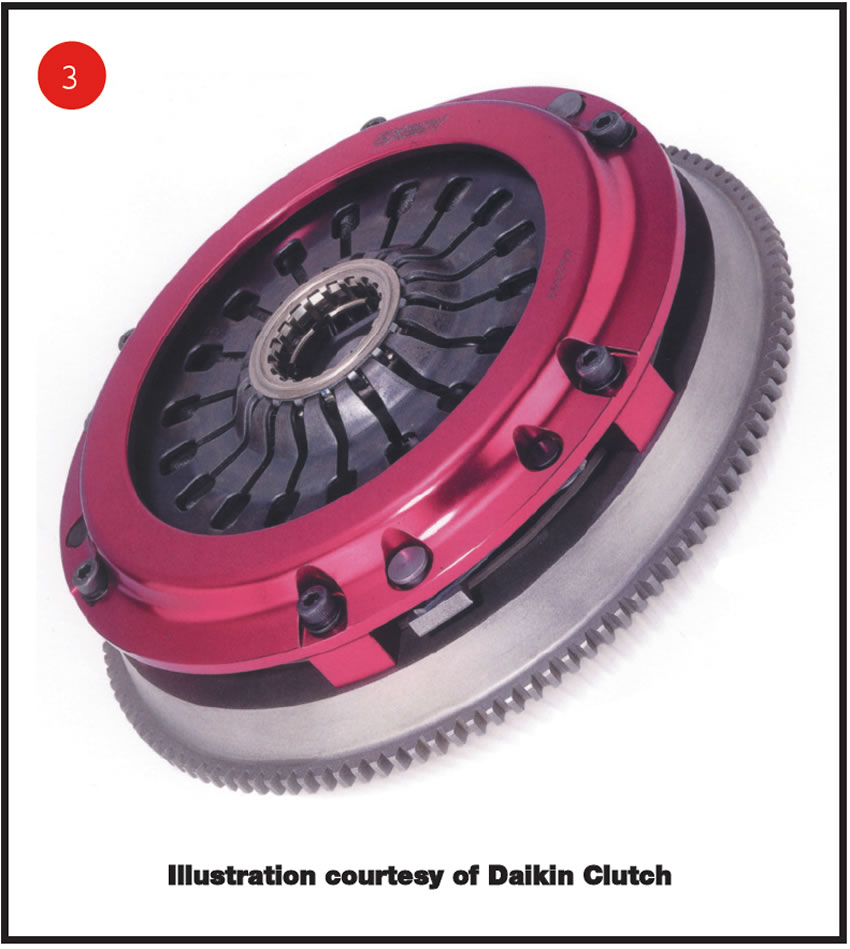

These replacement sets include a clutch cover (pressure plate), the clutch disc, a release (throw-out) bearing, a crankshaft pilot bearing or bushing, and usually a dummy spline tool to help you align the clutch assembly while torquing the pressure plate to the flywheel. The only profitable way to replace a worn or damaged clutch is to replace all of these components as a matched set. Beware of the shortcuts, such as changing just the clutch disc, as these components are matched at the factory and any mismatch in friction material or clamp load of the pressure plate will lead to a comeback.

These manufacturers are good enough for the OEMs, and they are the best for us. If you ever saw the quality-validation tests that they have to run to pass the quality-control people at the manufacturer level, you would never use a rebuilt clutch again. These clutch manufacturers trade product back and forth for efficiency, and many times you can get a set from one clutch company and find product in it from one of the others (see Figure 1).

A good clutch job will start with a thorough inspection of all the components that are involved in clutch operation. Just the clutch components alone are not the whole picture. Start with the clutch pedal and inspect it for wear at the pivot, damaged or weak return springs, bent or deflected pedal, stretched or frayed clutch cables, worn self-adjusters, and all the linkage and pivot points. If the vehicle is so equipped, inspect the entire hydraulic system. Look for leaks, worn or leaking lines, and cracked firewalls, and inspect the master cylinder for dirt and water.

Brake fluid, which is used to actuate the hydraulic system, is hygroscopic. This means it has the ability to absorb water vapor from the atmosphere. Water affects the master and slave cylinders in several ways: One, it doesn’t help the seals in the master and slave cylinders; second, many hydraulic systems have lines running near exhaust and other heat-producing items. If the brake fluid has water in it, the water can boil and produce some strange pedal problems that are hard to diagnose. Several companies market test strips that can be dipped into the brake fluid and will change color in the presence of water. If the water content is high enough, the line should be flushed thoroughly and the master and slave cylinders replaced.

Inspect the rear engine-crankshaft seal, cam plugs on the back of the block and the transmission to make sure no oil can leak on the clutch. The facings on the disc will fail very quickly with just a little oil on them. It pays to handle the clutch disc from the side, because even the natural oil on your skin can have an effect on the friction material.

Inspect the crankshaft for endplay. When the driver steps on the clutch pedal, the clamp load of the pressure plate, which is usually several thousand pounds, transfers to the crankshaft and the thrust bearing in the engine. If the thrust bearing is worn and the crank can move, you will never be able to adjust the clutch throw correctly.

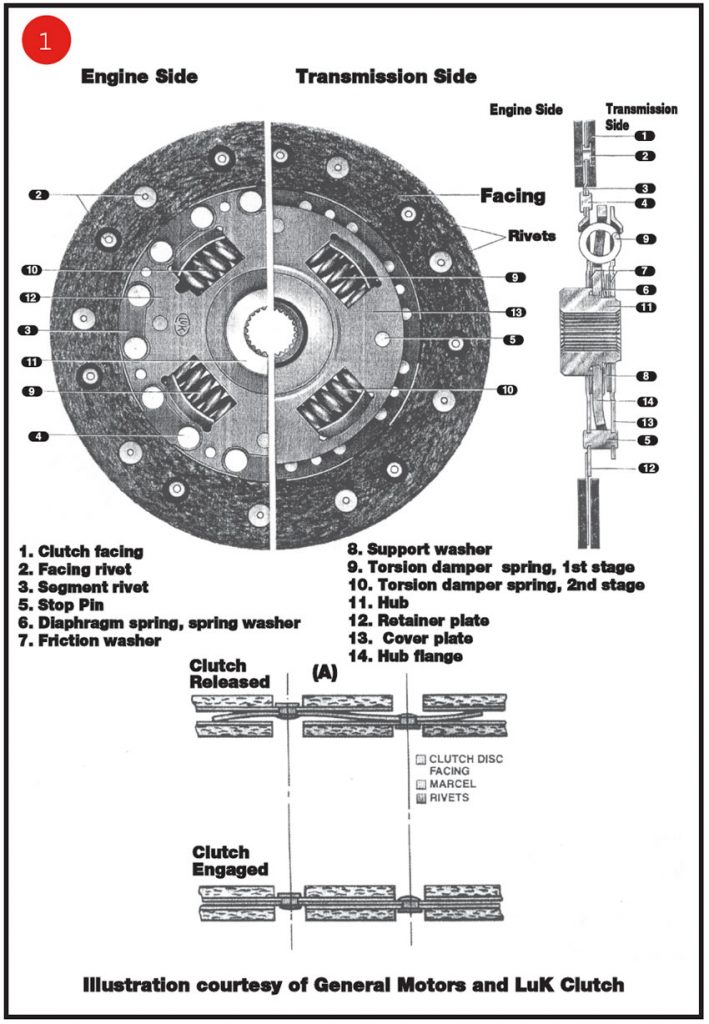

Once the transmission is removed, examine the bellhousing carefully for cracks and misalignment (see Figure 2). Make sure the dowel pins in the block are in place and that there is no wear. Misalignment of the bellhousing or transmission will damage the clutch-disc splines and the Marcel plate, causing a poor release and possibly gear jump-out in the transmission.

Next, resurface or replace the flywheel. Resurface does not mean sanding by hand or a whiz wheel. The flywheel must be ground flat and parallel to the crankshaft flange. You can’t do it on a lathe correctly, because the bit will skip over the heat spots and you will not get the proper flat finish. The correctly ground finish is necessary to meet the co-efficient of friction built into the disc. Any shortcut here will come back to bite you.

Replace the pilot bearing or bushing. Lightly lubricate the pilot bearing with a small quantity of high-temp grease. Do not lube a pilot bushing. These are made of oilite bronze material and are soaked in oil during manufacture. If you lube it up, the grease will carbonize and make noise in a very short time.

Now is the time to check the clutch splines on the main drive gear of the transmission and make sure they are not worn, damaged or rusty. Lightly grease the splines with high-temp grease, and fit the disc to the splines, making sure it slides as smoothly as on glass. Wipe off any excess lube so that centrifugal force can’t throw it onto the clutch components.

Examine the quill on the front bearing retainer to make sure there is no wear that can hang up the release bearing in its travel. A little wet sanding with 400-grit paper and solvent should do the trick. If it won’t clean up with light sanding, replace it.

Replace the flywheel onto the crank after making sure the crank flange is smooth and free from burrs or raised edges. Make sure to use the correct Grade 8 bolts and torque to specifications. You will never see damage like that from a 40-pound flywheel breaking or coming loose at speed. It usually goes right through the floor of the vehicle like a buzz saw.

Use an old input shaft or spline tool to align the disc while you hand-tighten the bolts that attach the pressure plate to the flywheel. Now torque the clutch-cover bolts by hand in a star pattern, a couple of turns at a time. This is no place for air tools. If you buzz the plate down one bolt at a time with air, you risk bending or distorting a new cover, with expensive results.

On flywheels with blind holes, make sure that the bolts for the clutch cover are not too long. They will bottom out, giving a good torque reading, but the excess play will kill the clamp load and the clutch will slip.

Use a jack when replacing the transmission. Never let the transmission hang unsupported on the disc, as the Marcel plate will bend and you will never get a proper clutch release.

Adjust the clutch to proper specifications, and bleed the hydraulic system to get all the air out. If you don’t own a reverse-bleed system from Phoenix Systems, buy one now. It will pay for itself in three clutch jobs. Remember that the plumbing on many hydraulic systems takes some bizarre turns, and every corner is a place to trap air. Some vehicles are notoriously hard to bleed. For instance, Ford Rangers like to hold air, and many times jacking up the vehicle to get the master cylinder level is necessary to release all the bubbles trapped in the system.

Drive it and deliver it. Congratulations; you just did a first-class clutch job that put added dollars into the repair order and should give your customer lasting use of the vehicle.

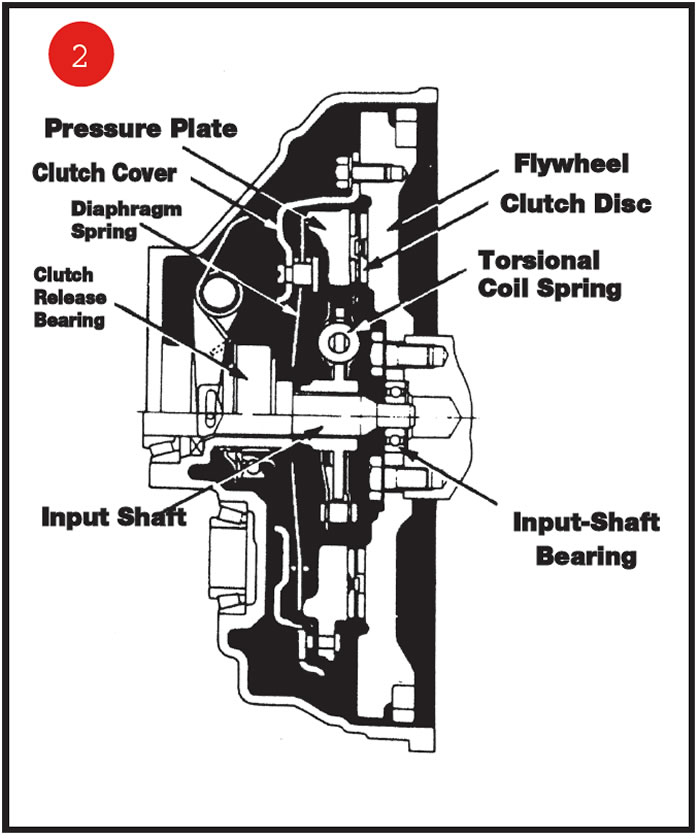

Speaking of added value and growing your business, look at performance clutches. There is a monster market for performance clutches in the import market. The muscle cars of today are the little Japanese and German rockets that make up the fastest-growing segment of the performance market. The import drags are the biggest growth factor in the NHRA, and they even have their own movie at the box office. If you haven’t seen “The Fast and the Furious,” rent it. The movie doesn’t have much of a plot, but it looks at the world of today’s car nuts. Street racing should not be glorified, but it gives a true picture of the buckets of money the kids will put into these cars.

Daikin Clutch has just released an import performance-clutch line that is what these guys want (see Figure 3). These are super-performing clutches that install just like any others, and you already have the knowledge and equipment. These clutches come with organic and cerametallic friction material, in single- and dual-disc models, at prices that leave you lots of profit margin. This line already is being used by most of the world’s top rally and racing teams and is another avenue to fill your bays with people who want to spend money. When was the last time you had a customer who wanted to have the clutch replaced? Daikin also has lightweight billet flywheels for added acceleration and safety. Work smarter, not harder. This is stuff for street cars that you can do with no extra effort.