Up to Standards

- Subject: Design, operation and diagnostic procedures

- Unit: MP3023/3024

- Vehicle Application: Late-model GM trucks

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor.

In this third part of the series on Magna Powertrain transfer cases found in late-model GM trucks, we look at MP3023/3024 (RPO code NQH). These units are known as ATC, or automatic transfer cases, which are computer activated and have five modes: Auto 4WD, 4HI, 4LO, 2HI and Neutral.

In the Auto 4WD mode, the unit will engage an internal wet clutch to bias torque from the rear wheels to the front wheels automatically with no driver involvement. The computer software program is tunable to provide more-advanced features that make the clutch response time extremely quick and create the proper torque load on the internal clutch without creating the driveline windup that causes crow hop and other NVH concerns at low speeds.

The computer receives wheel-speed signals from all four wheels and interprets a difference between front- and rear-wheel speeds as a slip. This engages the transfer-case actuator (motor) to apply the internal clutch to send power to the front wheels until the wheel speeds equalize, and then the electronics will release the internal-clutch pressure to return power to the rear wheels. This is known as torque on demand, and the program will preload the clutch pack at 5 lb.-ft. of torque at vehicle speeds under 25 mph and increase the torque load above 25 mph and increased torque levels from the engine.

As with any active or automatic transfer case – regardless of electronic actuation, viscous coupling or hydraulic-pump couplings – tire sizes and pressures are critical. These units may be driven on dry pavement in the Auto 4WD mode and the 2Hi mode. However, if the tire circumferences are not within 1/4 inch of each other and air pressure is not equal in all four tires, the computer will pick this up as a slip and activate the clutch.

Before you do anything else on one of these units you must MEASURE the tire sizes with a stagger gauge or a tape measure around the center of the tread. Only after all tires measure the same can you go on to other diagnostics. The sidewall labels on the tires will not help you; you need to measure. If there is more than 1/4 inch difference, the tire should be replaced and measured again, as tires even when new will grow to different sizes when inflated. It doesn’t take as long to measure the tires as it does to try to diagnose the problems caused by mismatched tires.

These units are controlled by a five-mode rotary switch on the dashboard. With the ignition switch in the run position the transfer-case control module reads the switch position to select the correct mode. If the driver rotates the switch to command a different mode, the light on the control switch will flash as the actuator motor on the transfer case selects the desired mode and will go to a steady state when all the parameters of the shift have been completed. Depending on the mode selected, other criteria may be needed. For a shift into 4LO the transmission must be in park or neutral and the vehicle speed must be under 3 mph. Shifting into Neutral requires the transmission to be in neutral or park, the rotary switch to be in the 2HI position prior to selection of neutral and vehicle speed to be under 3 mph.

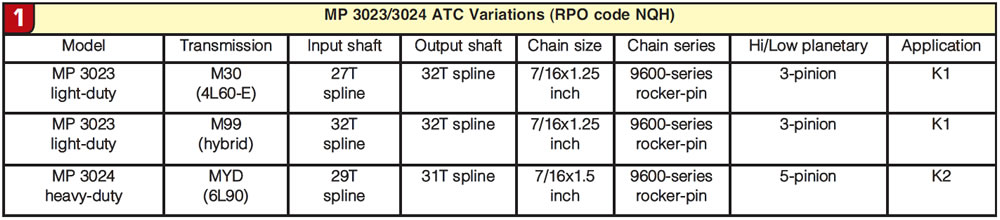

Figure 1 provides information on the two variations of the MP3023 depending on the transmission the vehicle uses. The only difference here is the input shaft being either 27 or 32 splines. These are considered light-duty transfer cases, with the MP3024 being a heavy-duty model that has a 29-spline input shaft, a 1.5-inch drive chain and a five-pinion low planetary assembly.

4LO position on all units has a 2.68-1 gear reduction, and when the driver selects that position the transfer-case control module will signal the transmission control module to change the shift pattern of the automatic transmission to allow correct shift timing for the lower gear ratio. There are some internal differences mechanically between the MP3023 and 3024. The 3024 HD model has heavier-duty bearings, seals, bushings and shaft. Also, the engagement teeth on the 3023 sliding sleeve are bias pointed and non-symmetrical; the engagement teeth on the sleeve and sprocket on the 3024 are symmetrical.

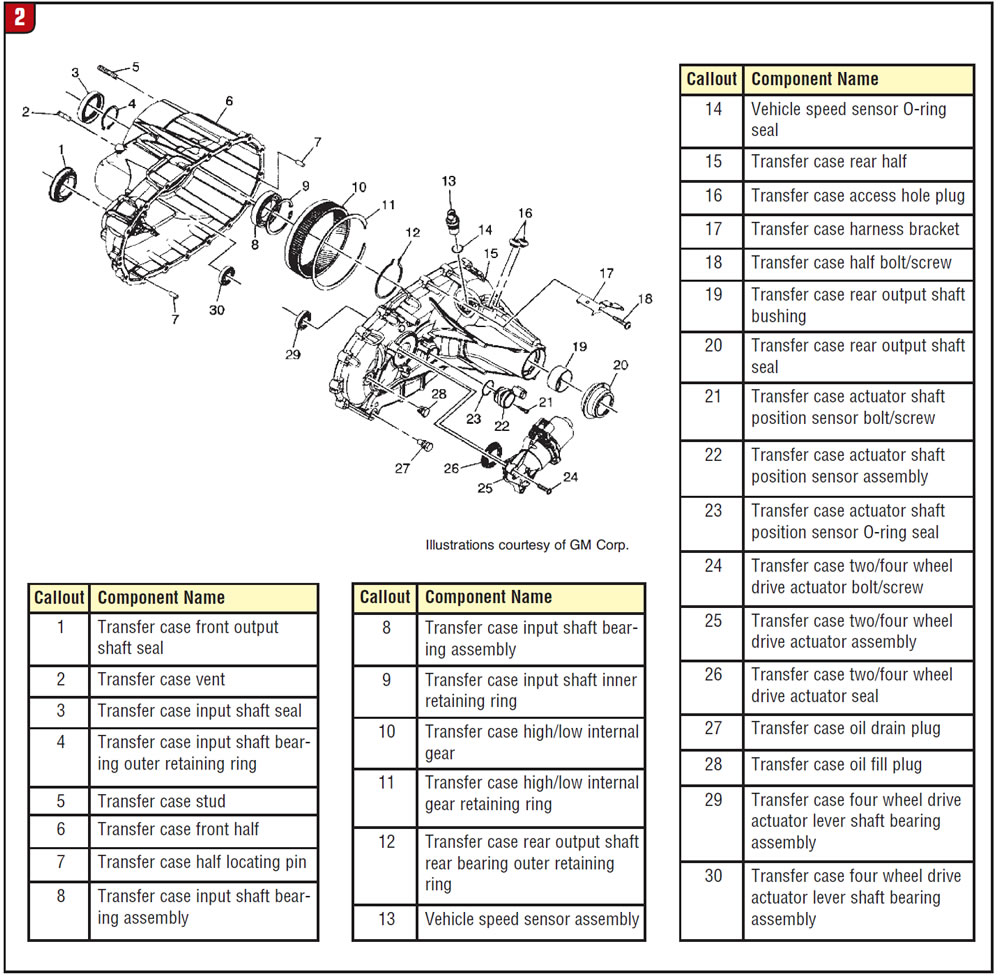

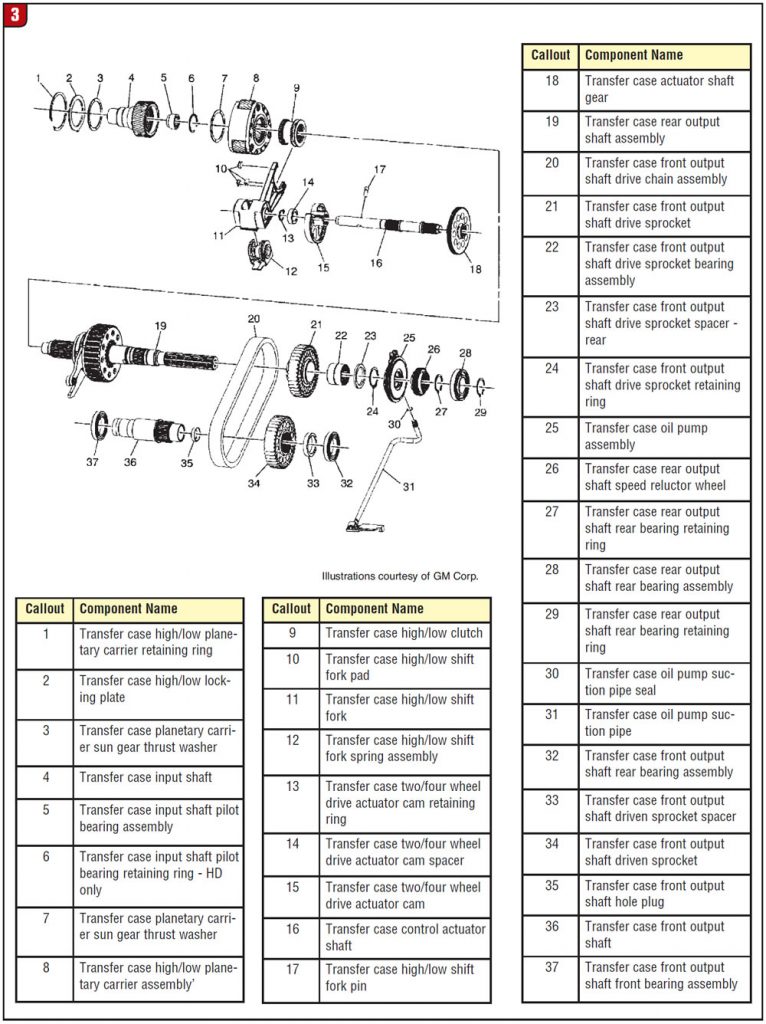

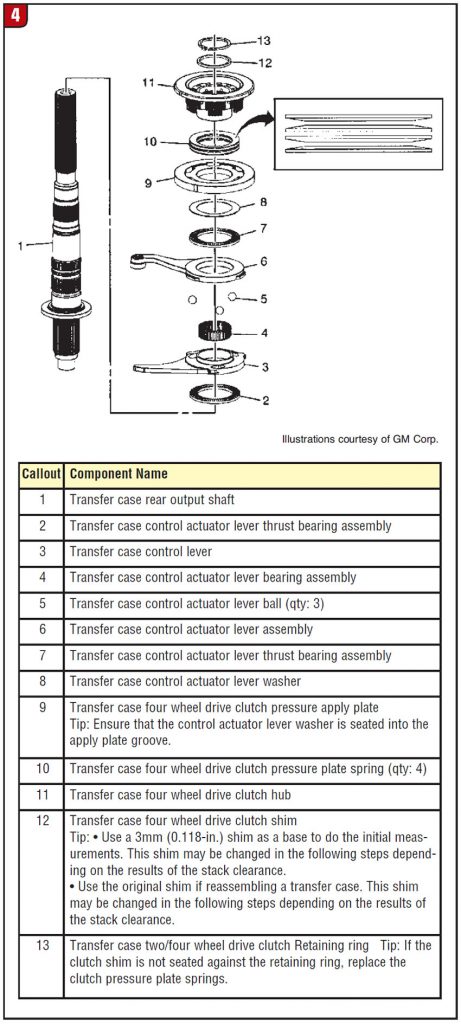

The internal-clutch application uses a ball-and-ramp design to apply the torque load to the clutch pack. You have seen this before, as the BW 4405 and 4411 use a ball-and-ramp system. Magna Powertrain uses a different design to apply leverage to the balls to force them up the ramp and load the clutch pack. Figures 2 and 3 identify the components of the unit, and Figure 4 provides a closer look at the mainshaft and clutch components. The previous designs from New Venture Gear (which Magna acquired from Chrysler) used a clutch fork that was moved by the encoder-motor assembly and the clutches had a considerable preload, which made low-speed operation subject to noise, vibration and harshness concerns. This is a refinement but more complex from a design and manufacturing standpoint.

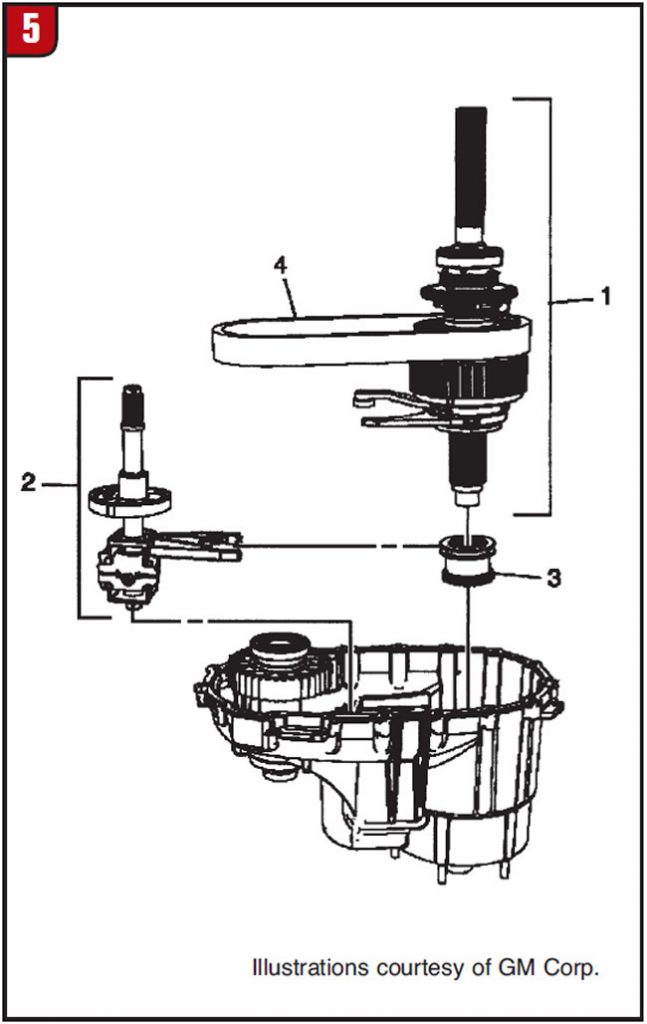

The actuator motor on the 3023 and 3024 has been relocated on the transfer case to enable the motor to apply torque to the two transfer-case control levers, which form a sandwich with the balls inside. One lever is moved by a cam that is driven by the actuator motor, acting like a scissor to push the balls up the ramp, and as the depth of the ramp declines the clutch is loaded. The first time you work on one of these, it will be critical to have an assembly manual to show the assembly procedure to follow to avoid breaking the cam. Essentially, you will have to install the assembled output shaft, low-range sleeve, and actuator-motor arm and cam together at one time into the case (Figure 5).

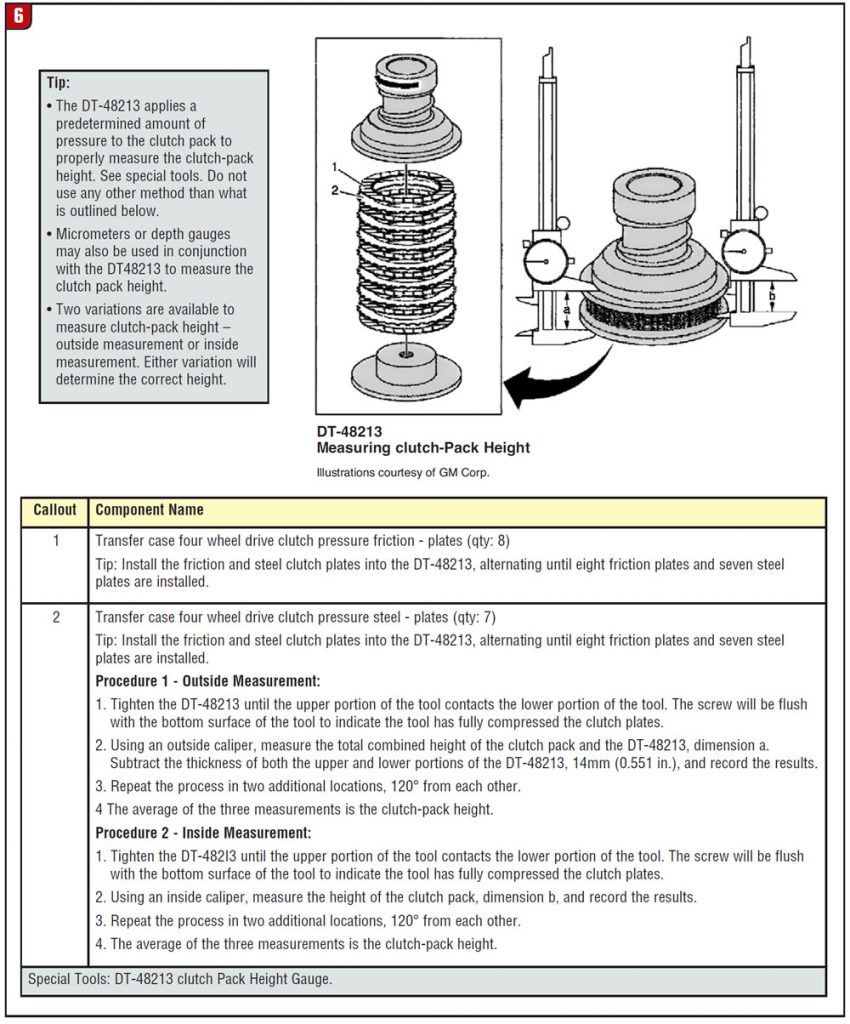

The clutch setup requires a special tool, # DT48213, to make sure the stack height of the clutch pack is correct (Figure 6). Also make note that the pressure-plate springs for the clutch pack are Belleville springs and must be stacked as shown. The clutch uses eight friction plates and seven steel plates alternating as in an automatic clutch drum. Measure at three locations 120° apart to arrive at an average height of the clutch pack.

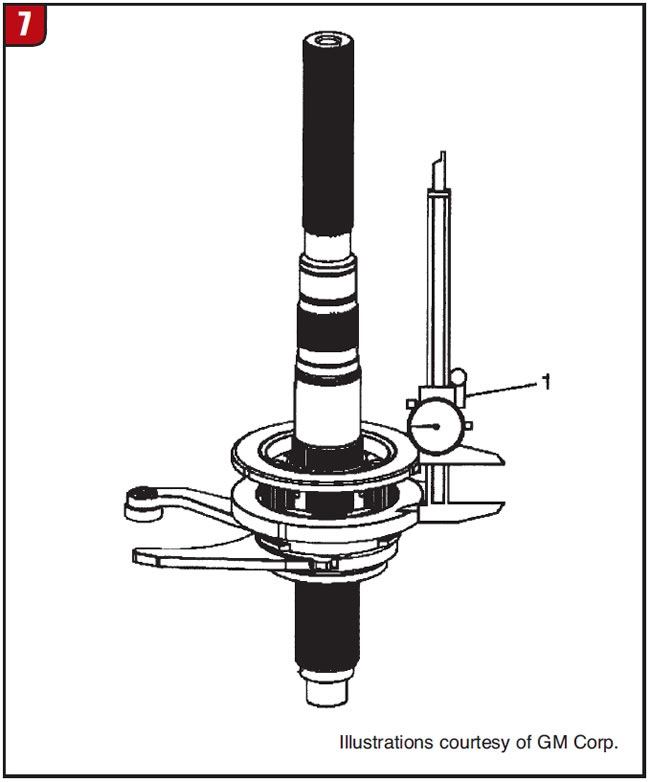

Using an inside caliper measure the clutch assembly loaded onto the output shaft (Figure 7) in three locations to obtain an average clearance of the components. Subtracting the clutch-plate stack height from the clutch-assembly height will give you the clearance of the clutch pack, and that should measure between 0.118 and 0.126 inch. There are shims available to adjust the clearance to the factory specs. Always start with the original shim or a 0.118-inch shim as a baseline. If the clutches are good and you are not replacing them, reuse the original shim.

The more things change, the more they remain the same. Different designs still have the same function and require common sense and a clear understanding of the function and interaction of the components internally and externally for the unit you are working on. As we see rapid advances in automotive technology, the one thing we know for sure is that we have to change with the times and continue our education. If we fail to do so we will be left behind quickly. Imagine that you take a six-month vacation and then come back to work. It will be a rude awakening to realize how many changes have occurred during that time. Technicians who make the effort to read and keep current add daily to their knowledge base. We know the fundamentals, we learn the advances.

Next month’s article will be devoted to the electronic diagnoses of the 3023 and 3024 active transfer cases.

Mike Weinberg is President of Rockland Standard Gear and Transmission Digest Contributing Editor.