Up to Standards

- Subject: Design and operation

- Units: MP 1222, 1225, 1226 transfer cases

- Vehicle Application: Late-model GM trucks

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

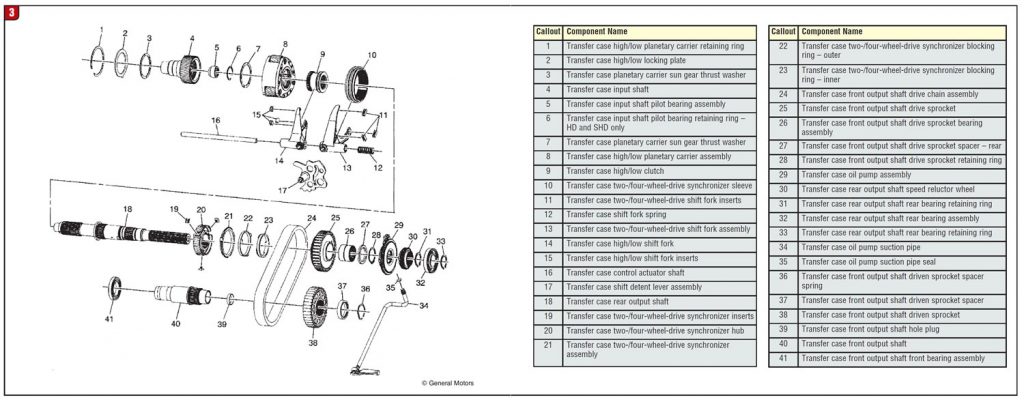

In last month’s article we identified and explored the basics of the Magna Powertrain transfer cases found in late-model GM trucks. In this article we take an in-depth look at one of the three series of models available: the MP 1222, 1225 and 1226 models, using RPO (regular production option) code NQG.

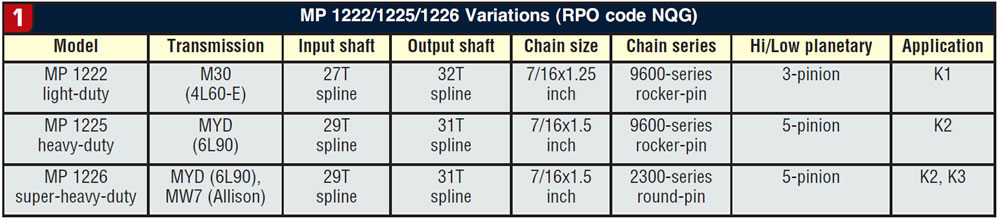

Understanding the significance of the RPO codes on GM vehicles will make parts ordering simpler. Figure 1 shows the variations and descriptions of the NQG series of transfer cases. As these units are used in K1, K2 and K3 models of trucks, there are differences in input and output splines, chain size and number of pinions on the planets. These variations provide the torque capacity necessary to cover the different engine/transmission combinations for light-duty, heavy-duty and super-heavy-duty applications.

Theory of operations

All the NQG transfer cases are two-speed, part-time units. They all have “shift on the fly” ability on the mode shifts. The vehicle operator can shift from 2H to 4H while driving by moving the floor-mounted shift lever to the 4H position with the vehicle in motion. During the shift a 4WD light mounted on the dash will flash until all the criteria are met for completing the shift. Once the synchronizer has fully engaged the drive sprocket, the front-axle disconnect locks the front axles and the electronic controls function, the dash light will remain on constantly.

Range shifts (engaging low or neutral) must be made at vehicle speeds under 3 mph. The electronic controls function once a ground is supplied through the transfer-case switch that engages the front-axle disconnect to lock the front axle. Once the ground is supplied and the front axle engages, the front-axle circuit informs the ECM (engine control module) and the antilock-braking system that 4WD mode is engaged. The ECM then forwards a signal through the GM LAN serial data bus to turn the dash light on steadily.

Selecting the 4WD Low range causes the transfer-case switch to send a ground to the front-axle actuator on a separate low-range circuit. The ECM then will modify the shift pattern of the transmission to compensate for the gear reduction in low range so the shifts are not stacked. The ECM accomplishes this by sending a signal to the transmission control module (TCM), which changes the software for the shift schedule to function with the change in low-range gear ratio.

These units are not to be driven on dry pavement in the 4WD ranges, since there is no way to compensate for driveline windup resulting from turning-radius issues. Shifts to low range should be made with the vehicle transmission in neutral and vehicle speed under 3 mph, as there is no way to synchronize the planetary engagement. The neutral position must be reached in the same way – transmission in neutral and speeds under 3 mph.

The neutral position permits the vehicle to be towed. The neutral position operates as if the transfer case were in the 4H position, with both front and rear output shafts turning. The rear output shaft is turning the oil pump in the transfer case to provide constant lube to the components, and the front output shaft will turn the front prop shaft, but the front-axle disconnect is not engaged, so no power is transmitted to the front wheels.

Although these units are manually shifted, you can see that there are a number of electronic issues involved with the front-axle-disconnect actuator, the ECM, TCM and transfer-case switch. Do not pull one of these units out for repair or replacement unless you have spent some time making sure all the electronics are functioning correctly. Time spent here will stop sales of unnecessary repairs and a lot of wasted labor.

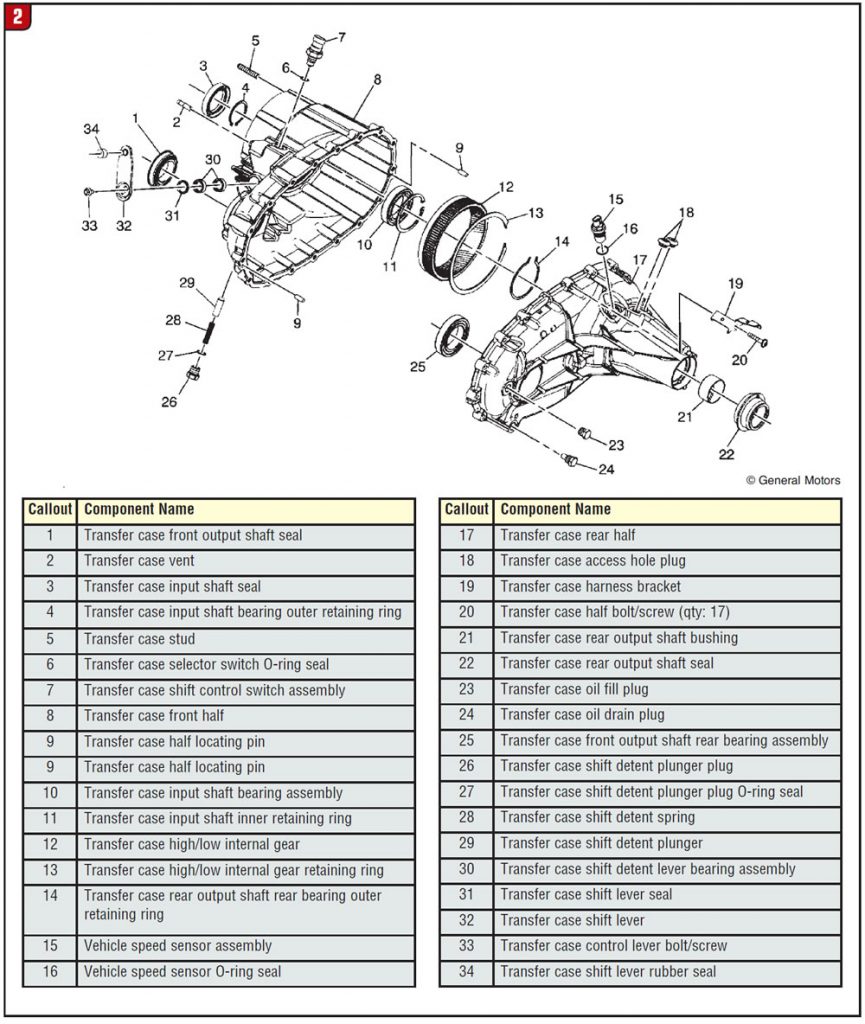

Differences in internal parts

It should be apparent from looking at Figure 1 that there will be differences between the three models of NQG units. Following are some basic specs to help you when you need to replace parts. It is common to take advantage of a good core in making a repair, but there is a big difference between the MP 1222 and the MP 1225 and 1226 models that you need to understand.

MP1222

- Input-shaft seals are of a dual-lip design, necessary because the transmission adapter housing is filled with fluid.

- The smaller transmission output shaft (27 splines) uses a smaller input-shaft bearing, with a 1.5-inch outer diameter.

- The synchronizer for drive-sprocket engagement has bias pointing on the leading edge of the engagement teeth. This means that each tooth is slanted across the entire face rather than having symmetrical points.

- The 32-spline output shaft is smaller than those in the heavier-duty units.

- The driven and drive sprockets are 1.25 inches wide to accommodate the smaller drive chain.

- The snap rings that retain the rear-output-shaft bearing are smaller; the snap-ring grooves measure 1.476 inches.

- The rear output shaft uses a smaller bearing, with an internal diameter of 1.575 inches.

- The rear-output-shaft bushing and seal are smaller, and the rear case half has smaller bores.

MP1225/1226

The MP1225 uses a single-lip input seal, as the MYD (6L90) transmission has a dry adapter housing. The MP 1226 uses a dual-lip input seal, as the transmission adapter housing is filled with fluid.

Because of the larger 29-spline transmission output shaft, the input-shaft bearing in the transfer case is larger, measuring 1.625 inches.

- The input-shaft bearing is retained in the case with a retaining ring.

- The synchronizer for the drive sprocket has symmetrical engagement teeth.

- These units use a larger rear output shaft.

- The drive and driven sprockets are 1.5 inches wide for the heavier-duty drive chain.

- The rear-bearing retaining rings for the rear output shaft are larger (1.516-inch journals).

- The inner diameter of the rear-output-shaft support bearing is 1.614 inches, larger than that of the MP1222.

- The rear case half has larger bores and larger bushings and rear seals.

These units are found in a large number of popular GM trucks and should provide a good volume of work for us as the vehicles age or their owners abuse them. These are not complex units, but diagnosis on all vehicles has become much more complex as the systems that they interact with become more electronically advanced. It is easy to get in trouble by concentrating all your attention on one component (the transfer case) that seems to be the problem. The few minutes you spend in a thorough diagnostic routine before pulling the unit will pay you dividends in really understanding the problems, writing more-profitable repair orders that include all the parts needed and cutting wasted labor out of your day. Overlooking something as simple as a bad ground can put a real hole in your bottom line. The transfer case is only one part of many that make the vehicle function.

Next month we will look at RPO code NQF MP models 1625/1626.