Technically Speaking

- Subject: Solenoid performance code

- Unit: 41TE

- Vehicle Application: 2007 Chrysler Sebring Coupe

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

Without question, aside from P1776 (47), one of the most-common trouble codes plaguing Dodge/Chrysler vehicles is P0750 (or 41), “Low/Reverse Solenoid Circuit error,” in 41TE-type transmissions (see Shift Pointers, October 2008). This is purely an electrical code and typically points to the solenoid, the wiring (which includes the connectors) from the solenoid body to the TCM, or the TCM itself. In so many instances on our technical hotline the cause has been a defective TCM. What becomes very frustrating is out-of-the-box remanufactured TCMs coughing up the same code as soon as they are installed; makes you think you missed something in your previous diagnosis.

Just recently John Thornton from Autotrain Inc. ran into another scenario that caused this code to set and was kind enough to share it with me. Now, keep in mind that all too often when this code pops up usually the first line of attack is to throw a solenoid body at it (sometimes this can be a literal act!). If that doesn’t work the wiring might be replaced, followed by a TCM.

Admittedly, a good portion of the time the code is resolved by one of these three methods; that is, if you happen to get a good remanufactured TCM. Otherwise, this code will drive you crazy, and out of desperation you finally use a meter or scope to locate the problem. After all, when everything has been replaced and the status of the code remains the same (a new Zeppelin song), everything is still up for grabs. Except in John’s case, which – as you will see – is a testimony to hooking up a scope first to see what’s going on. And sometimes we get blindsided with pattern-failure repairs and end up throwing parts at the car to see what works.

The vehicle was a 2007 Chrysler Sebring Coupe (JS) 2.4L with a 41TE sporting the P0750 code. The unit had been replaced twice, and what makes this particular vehicle of interest is that it has the Global Powertrain Engine Computer (GPEC) (Figure 1) instead of the old 60-way TCM. Could this mean that GPECs as well as the previous New Generation Controllers (NGC) 3 & 4 are cursed also?

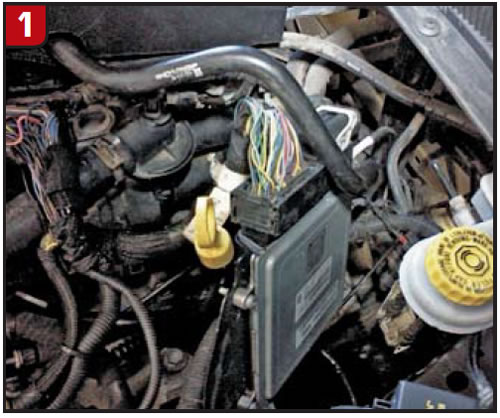

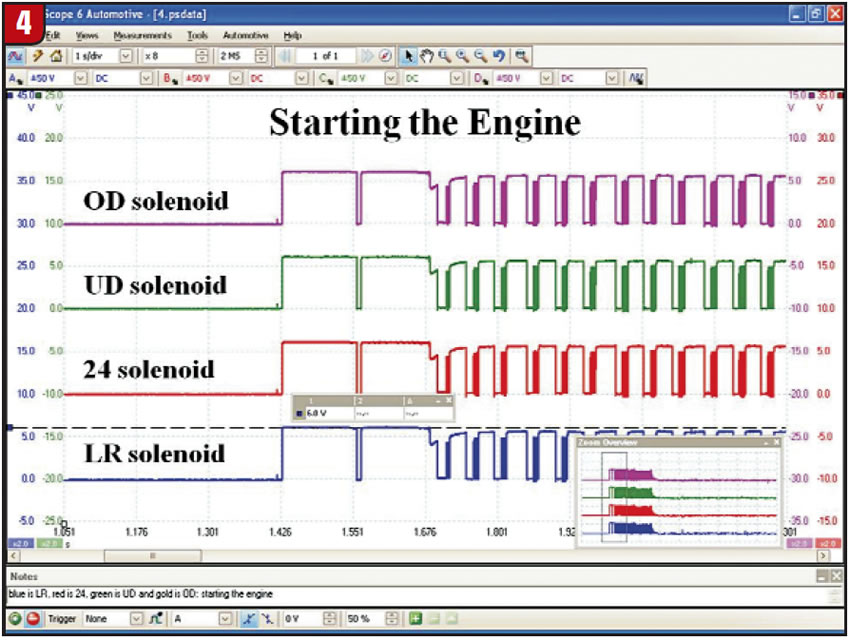

After verifying the presence of code P0750 John attached his scope to each of the four solenoids and cycled the key to the on position (engine off). The GPEC did an initial cycling of the solenoids (Figure 2).

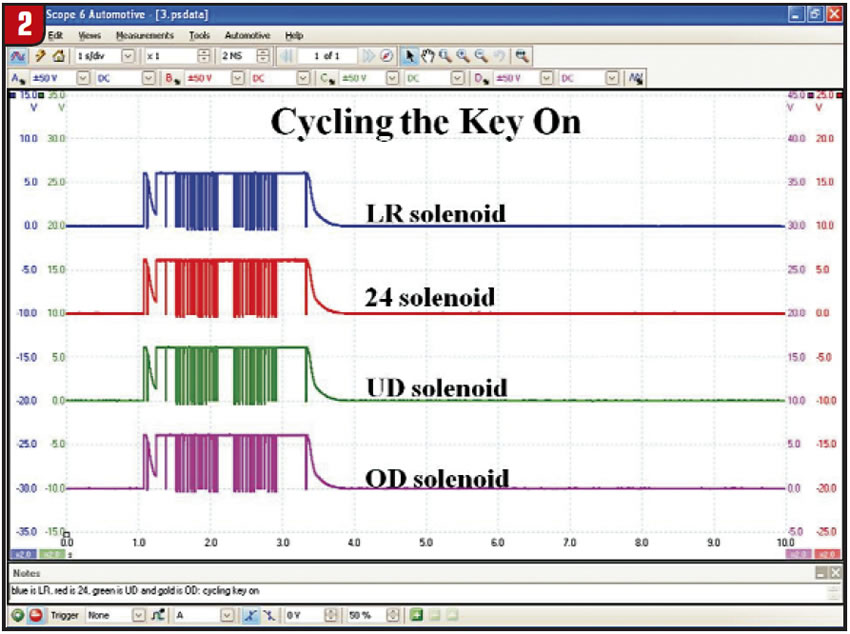

To an eye accustomed to viewing this type of data two things immediately become apparent: The typical inductive spike is missing, and all four solenoid voltages are half of what they should be (Figure 3).

These solenoids are supplied with system voltage via a relay. The computer pulses these solenoids to control shift scheduling as well as shift feel (clutch pressure). In so doing, it also continuously checks the integrity of each of the four solenoids’ circuitry by quickly turning the solenoid off. This causes an inductive spike (fly-back voltage) that typically is in the range of 42 volts.

With two issues immediately observed, the engine was started (Figure 4) and the same two issues remained, even with the alternator now in play. Since all four solenoids were behaving incorrectly in the same way and all four receive the same voltage supply, the next logical diagnostic step is to check this common voltage supply.

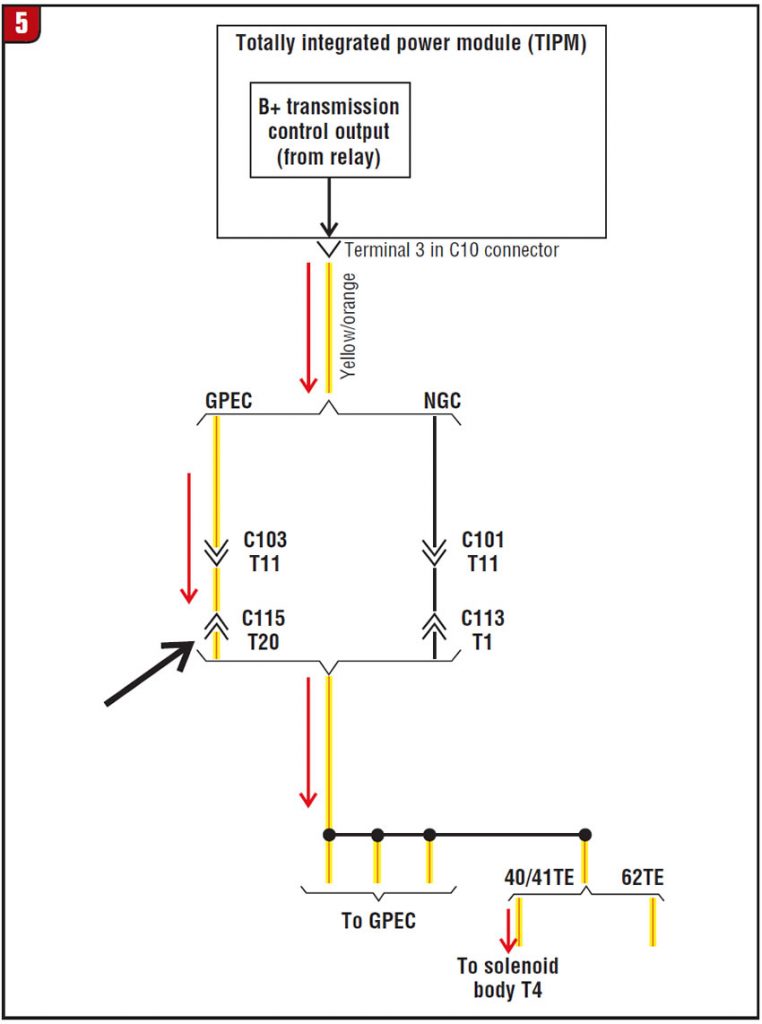

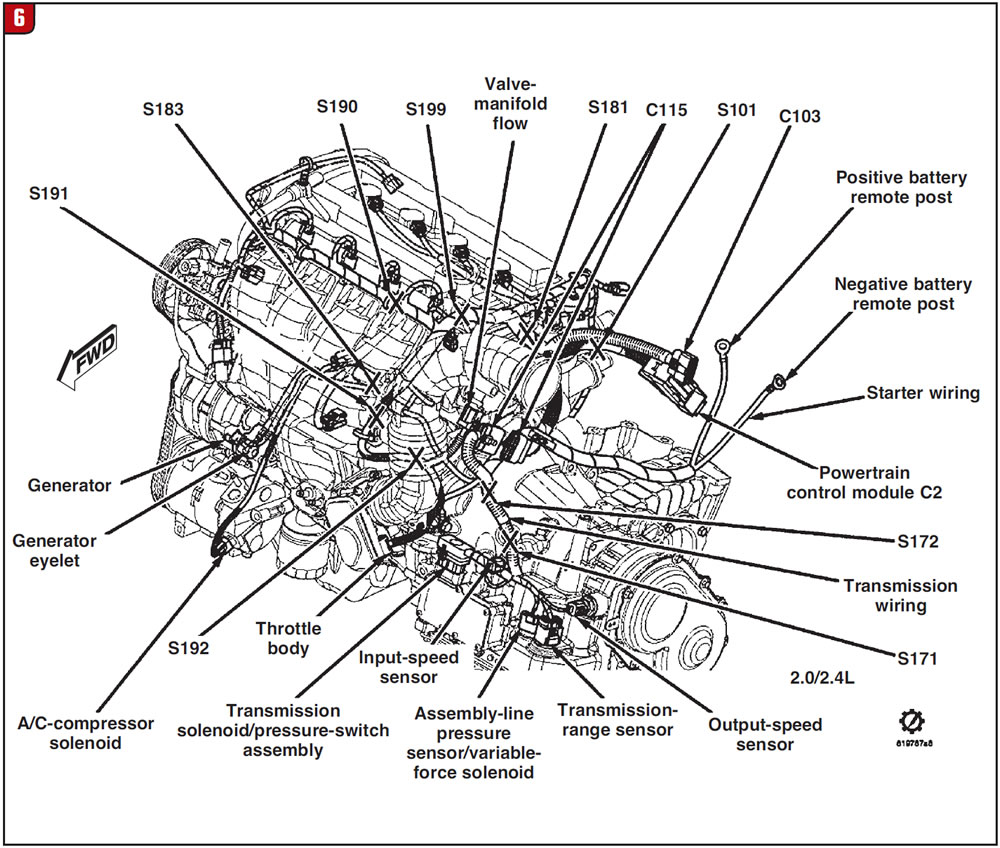

At this point John referred to a wiring diagram (Figure 5) and decided to check this power source at connector C115, terminal 20, on the relay side of the connector (figures 6 & 7).

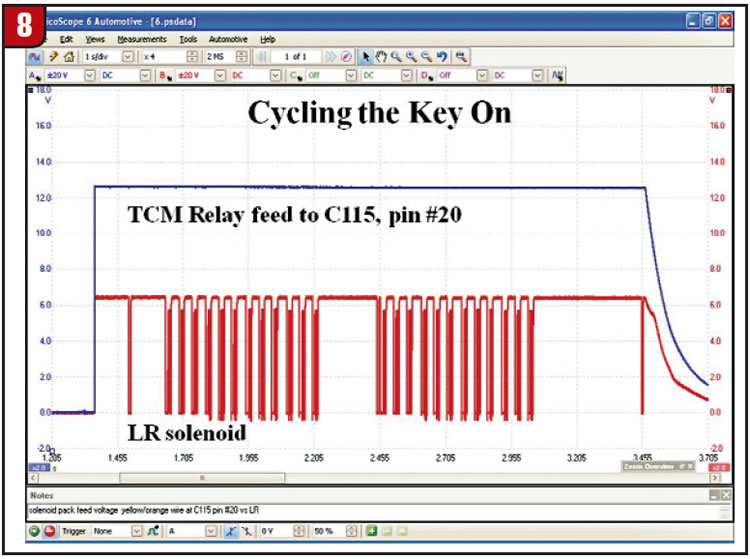

With the scope hooked up to both the power source and the low/reverse solenoid on the opposite side of the connector and the ignition turned on, you can see full power to the connector with a voltage drop to the low/reverse solenoid still present (Figure 8). You can also see how quickly the computer recognized a problem, as evidenced by the power supply going to 0 because of the relay being turned off.

This indicated that there might be a problem with the connector itself, so John quickly put a jumper wire in place (Figure 9).

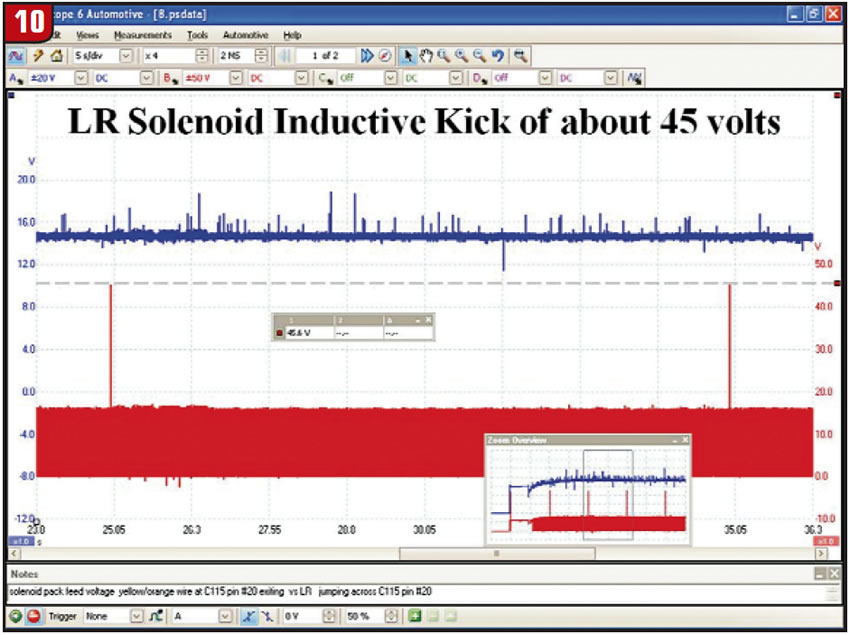

Once this was done, the low/reverse solenoid came back to life, being pulsed on and off at full battery voltage along with a 45-volt inductive spike (Figure 10). With this inductive spike the computer can determine the integrity of the circuit. If it’s too high or too low, the P0750 code sets. With the old 60-way TCM this spike is around 42 volts. With this new GPEC (in use since the 2007 model year) the spike is not as loaded down so it hits the 45-volt mark.

The one question you may be asking yourself is if all the solenoids were affected by a common power supply, why did only P0750 come up? This is a good question. When these vehicles start up, the low/reverse solenoid is the first one the computer looks at. If there is a hard fault with this circuit, the low/reverse code will set before the computer looks at any others. This may explain why in the past you may have seen a wire problem for the low/reverse solenoid. After it was repaired, you suddenly had another code for the 2-4 solenoid, as it too had a wire problem. Since the low/reverse set first, the computer didn’t look further. Once low/reverse was repaired, the computer then moved on to the next solenoid to be checked, the 2-4.

The correction for this vehicle was to do a simple, inexpensive, 30-minute repair of the connector.