- Author: Mike Weinberg

- Subject Matter: QuadraTrac transfer cases

- Issue: Tire size is crucial

In 1973 Jeep introduced the QuadraTrac transfer case, designed and built by Borg Warner. Jeep, now part of Chrysler, which is now part of Fiat, trademarked the QuadraTrac name and continues to use it today. In 2011 Jeep introduced several new transfer cases for the Jeep Grand Cherokee models. There are three systems available providing 4-wheel drive: Quadra-Trac I, Quadra-Trac II Active on Demand, and Quadra-Drive II equipped with an Electronic Limited-Slip Differential (ELSD). This gives us three new transfer cases to learn about.

Quadra-Trac I is standard on Grand Cherokee Laredo with a 3.6L engine. The transfer case is the MP2010 (also called ITC for Integrated Transfer Case), which is a full-time, single-speed transfer case. The driver has no control or input into this system. Using an open-center differential inside the unit, torque is split 50/50 to the front and rear axles. Torque is constantly transferred, providing constant improvement to the vehicle’s stability. Invariably depending on conditions, there will be some wheel slippage that is handled by the Brake Traction Control System (BTCS), which will use a brake caliper to slow down a slipping wheel and transfer torque to the wheels that have grip. All of this occurs without any action by the driver.

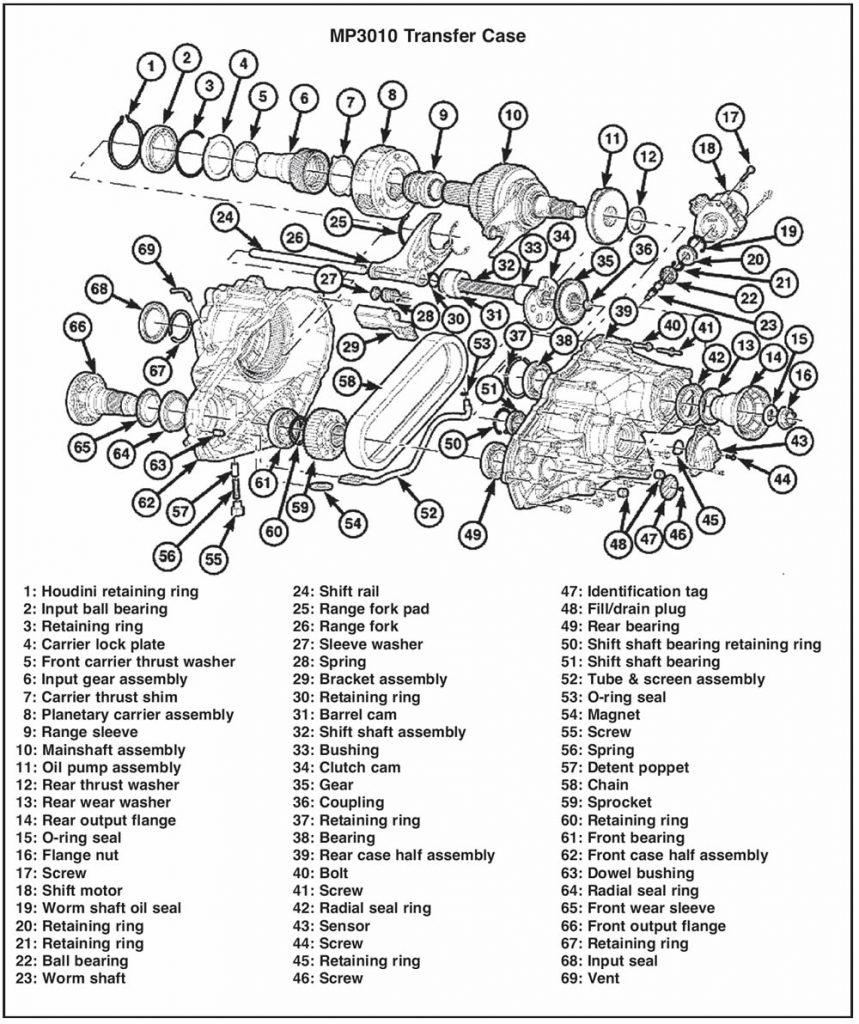

Quadra-Trac II Active on Demand is standard on SRT8 models of the Grand Cherokee. Using an MP3010 single-speed transfer case and uses an electronically control ELSD, which splits torque at 47% to the front axle and 53% to the rear axle with no driver input. The torque is transferred through an electronically actuated multi-disc wet clutch pack inside the transfer case. The Drive Train Control Module (DTCM) applies the clutch pack at the 47/53 torque split in normal dry road conditions and is capable of adding torque to the axle that needs it under slip conditions. The electric motor on the transfer case applies the clutch pack to increase torque and the ELSD transfers torque on the rear end to the axle with traction. This is a one-speed full-time transfer case.

Quadra-Trac II is standard equipment on the Grand Cherokee Limited and Overland models with 4-wheel drive. It uses the MP3023 two-speed computer-controlled transfer case. This is an electronic transfer case that uses a wet-pack clutch internally to transfer torque to the front and rear axles depending on need. This is a full-time unit and has electronically controlled shifts.

It has a console-mounted switch that has 4WD Auto and 4WD Low positions, with a push-pin button to achieve a neutral position to allow for flat towing. The 4WD Auto is for all normal driving and torque is constantly being redirected to the wheels that need it. 4WD Low when engaged is for off-road use only and should not be driven on dry pavement. In the low position, the clutch pack is fully locked and torque is split 50/50 front and rear and is only intended for part-time usage. The low gear planetary set changes the ratio from 1-1 to 2.72 -1 for enhanced traction in heavy snow or off-road use. To protect the driver, the vehicle is equipped with an Electronic Stability Program (ESP) and Traction Control, which works together with the DTCM to correct any under- or oversteer issues and control vehicle speeds in turns and underbraking. An available option on Overland 4X4 2012 and up Limited on Overland – and standard on Overland Summit models – pairs this system with ELSD rear end for maximum torque transfer.

As you can imagine there is a very complex electronic interface in all of these systems, and the diagnostics for them will require another article. One of the most critical factors that is often overlooked or ignored on these all-wheel drive systems is tire size. All four wheels must have equal size tires, same type of tire, equal and correct tire pressures and tire circumference to within a quarter-inch on all four wheels. This is always the place to start when trouble shooting any 4WD system. Incorrect or mismatched tires will create damage to the transfer case and create a monster diagnostic time waster. As usual, if you are repairing transmissions, transfer cases and rear ends, you will become a perpetual student and remain so throughout your career. If it was easy everybody would be doing it.

Mike Weinberg is president of Rockland Standard Gear.