Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Lepelletier planetary system

- Units: ZF 6HP, Aisin AA80E

- Issue: Design and operation

Jump from 4 speeds to 8 speeds – without adding much iron

There was a time, long ago, when four-speed automatic transmissions roamed the earth. Big, heavy monster transmissions like the GM Hydramatic and Jetaway helped to propel the vehicles of that time. However, by the early ’60s, the winds of change started to blow and the focus shifted to lighter-duty three-speeds.

That would have been it but for the fuel crisis of the ’70s and how to address the problem. The fix, of course, was more gears and lockup torque converters. One approach to that change was to add more iron. Case in point: GM took the TH200 and added an overdrive planet set, drum and clutches to create the 200-4R. Ford jumped on the C3, which became the A4LD, and Chrysler followed suit by adding a whopping tail section to Torqueflites, which became A500 and A518 models.

When it became apparent that four speeds weren’t enough, the games began by adding more gears. ZF stepped up to the plate in the early ’90s by launching several new-design five-speeds that involved a lot of stuff. Ford took a simpler approach by turning an A4LD (4R55E) into a 5R55E, mainly by computer strategy cycling the OD section on twice.

Without a significant change in thinking, though, stepping up to six or more speeds would have resulted in a transmission weighing a ton. The answer to the problem was the Lepelletier planetary system.

In 2002, ZF released the 6HP family of transmissions, which use the Lepelletier system. Although there are now several variations of the system used by different manufacturers, the basic premise is the same.

The ZF 6HP models (Ford 6R60, GM 6L80) with Lepelletier consist of a Simpson (simple) front-planet set and a Ravigneaux (compound) rear-planet set. Together, they provide six forward speeds while using only five clutch packs. So, how is that possible? Let’s start with the four-speed 4R70W.

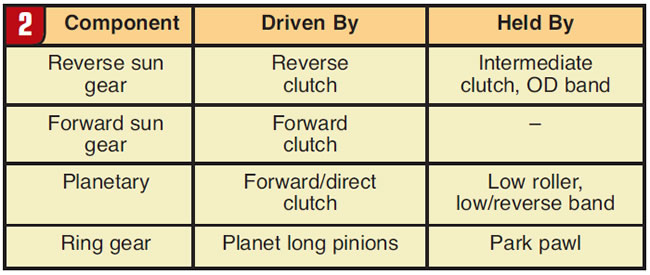

The planetary set in the AODE/4R70W family consists of the reverse (large) sun gear, forward (small) sun gear, compound planet with short and long pinions, and a single ring gear (Figure 1).

Figure 2 shows the operation of the components.

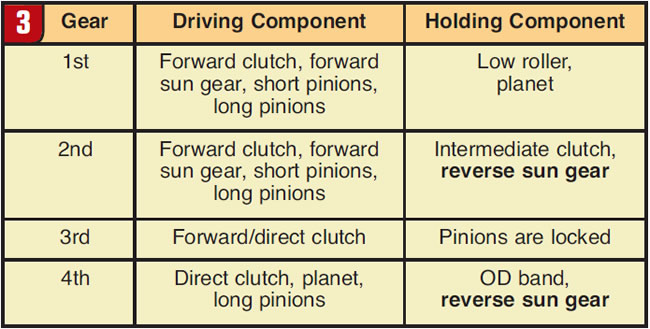

Figure 3 shows the transmission power flow.

Now imagine that in addition to the reverse sun gear being held stationary for 2nd and 4th, the sun gear could also be driven at different rates of speed. That would provide more gears, which is the case with the 6HP family of transmissions.

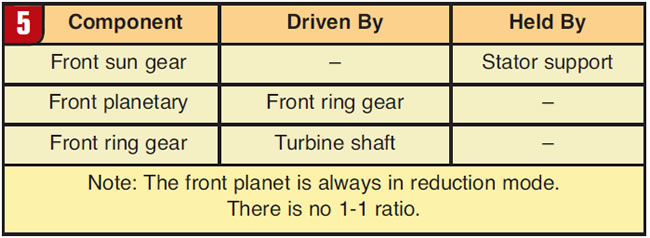

The back end of the 6HP is comparable to the 4R70W. The front end of the unit is where it differs, due to the front (simple) planet set (Figure 4). The key to this arrangement is the sun gear, which is anchored to the stator support and cannot turn.

Figure 5 shows how the front components operate.

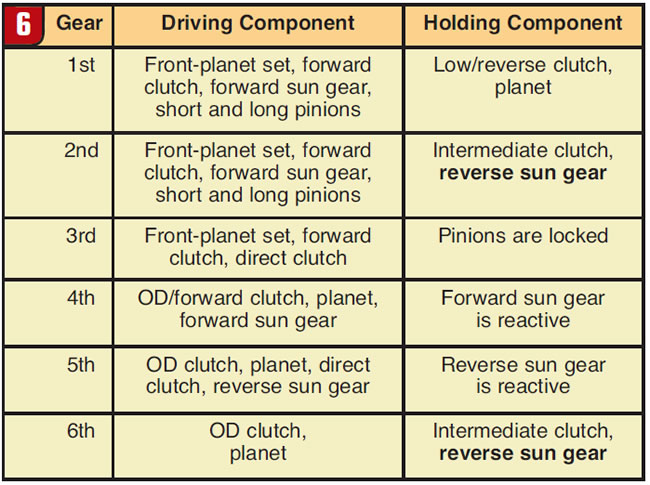

Figure 6 shows the transmission power flow.

First, second, fourth and sixth gears are somewhat comparable to those of the 4R70W. By adding one simple planet set and one clutch pack (kind of), two additional gears were achieved.

But an eight-speed? Is it possible to squeeze out two more gears beyond the 6HP? Apparently it is, since that’s exactly what Aisin did by developing the AA80E in 2007.

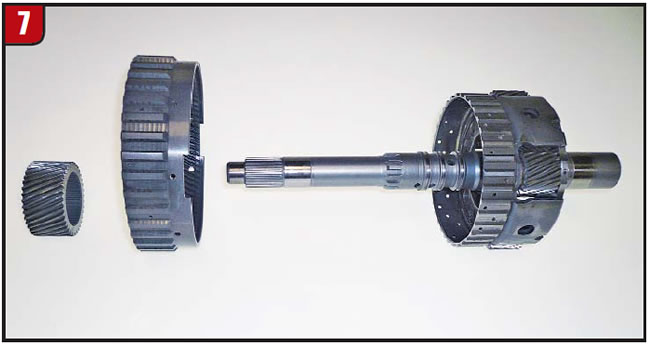

The layout of the AA80E is slightly different from the 6HP, in that the turbine shaft is made to the front planet instead of the front ring gear as in the 6HP (Figure 7).

Three clutches have effect on the reverse sun gear, and the C2-clutch drum is splined to the turbine shaft (Figure 8). There is also one more clutch than in the 6HP. The AA80E has a low one-way clutch (OWC), whereas the 6HP did not – until recently, that is. In 2011, the Ford 6R80 model had a low diode added to it.

The compound planet set is also slightly different from that of the 6HP (Figure 9). The reverse sun gear is made to a shell, and the planet has splines for the OWC. The hub for the C2 clutch bolts to the back of the planet.

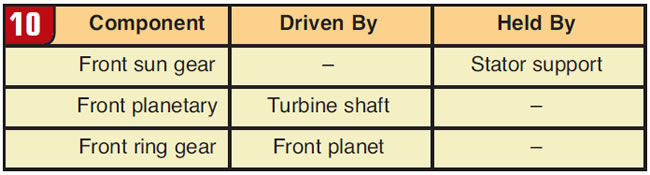

Figure 10 shows the operation of the front components.

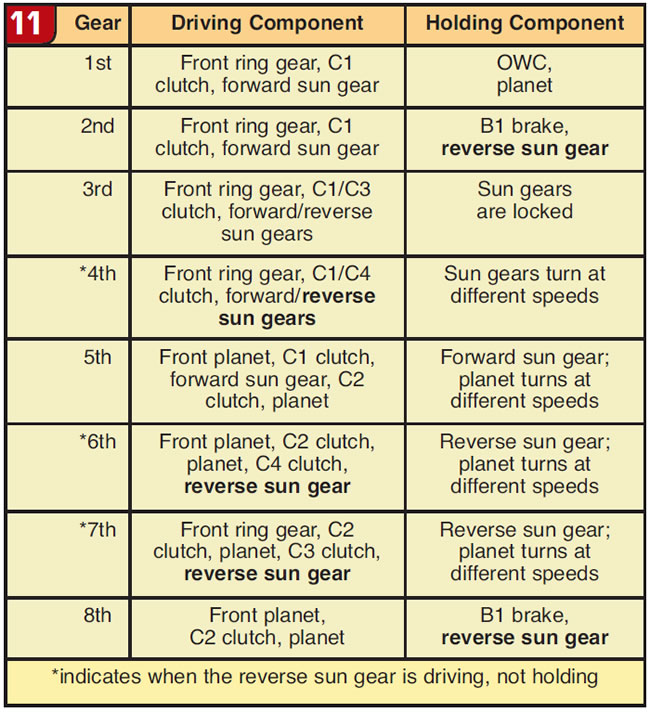

Figure 11 shows the transmission power flow.

Normally, when two apply components affecting the same planet are on, the planet would be locked up, 1-1. With the constant reduction mode of the front planet of Lepelletier, various gears are possible within the same system.

In the end, designing an eight-speed transmission comprised of only two planet sets and six clutch packs is no small feat. It will be interesting to see how many more speeds can be squeezed out “without adding much more iron.”