After overhaul and torque-converter replacement, 2006-up Dodge trucks equipped with the MDS multi-displacement 5.7-liter Hemi engine and the 545RFE transmission may exhibit a complaint of torque-converter shudder between 30 and 40 mph.

The cause may be that an incorrect torque converter was installed. There are two types of the 5.7 Hemi engine: a full-time V-8 and an MDS multi-displacement V-8. The MDS engine goes from eight cylinders to four within 40 milliseconds by deactivating valve lifters, spark and fuel. MDS activates when there is little to no load on the engine, as in highway driving.

The torque-converter-clutch lining on the MDS type has reliefs that go all the way through the lining. The converter with this type of TCC lining must be used or a shudder during partial TCC application may occur. Diagnostic trouble code 74/P1799 “Calculated Oil Temp. in use” may also set as a result of the TCC shudder, which may stop cylinder de-activation and result in poor fuel economy.

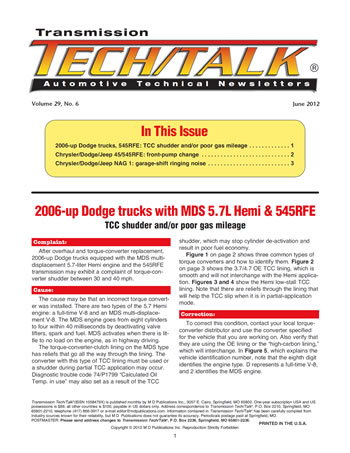

Figure 1 shows three common types of torque converters and how to identify them.

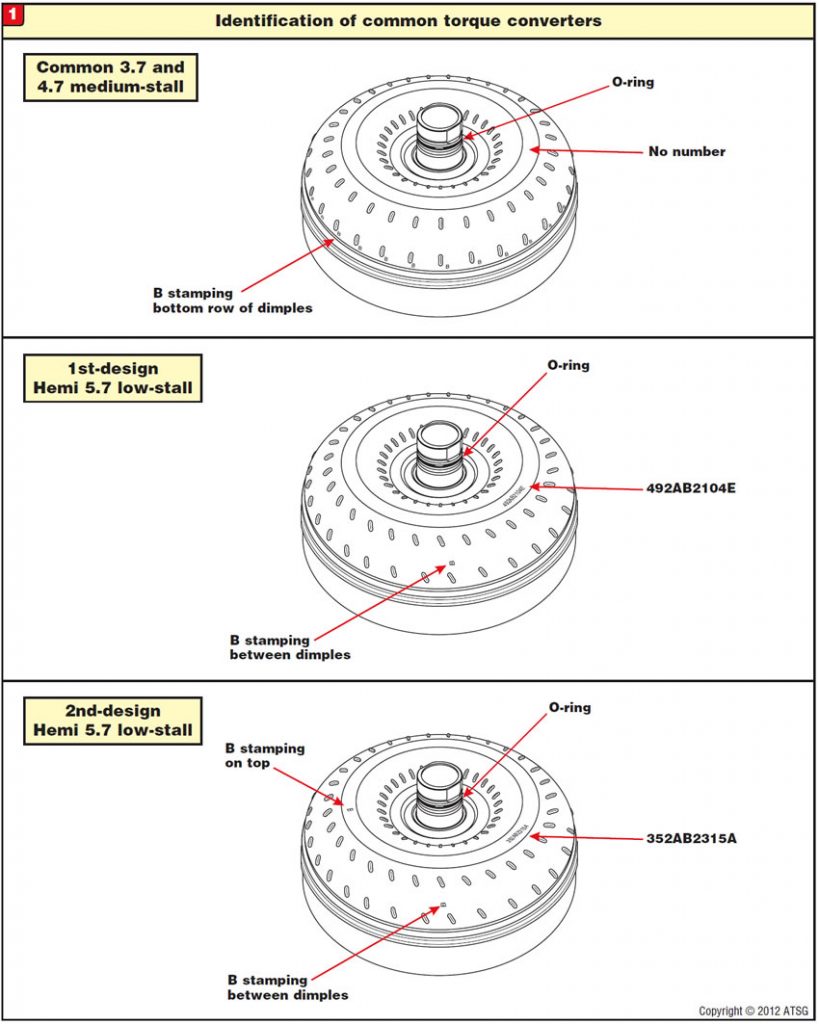

Figure 2 shows the 3.7/4.7 OE TCC lining, which is smooth and will not interchange with the Hemi application.

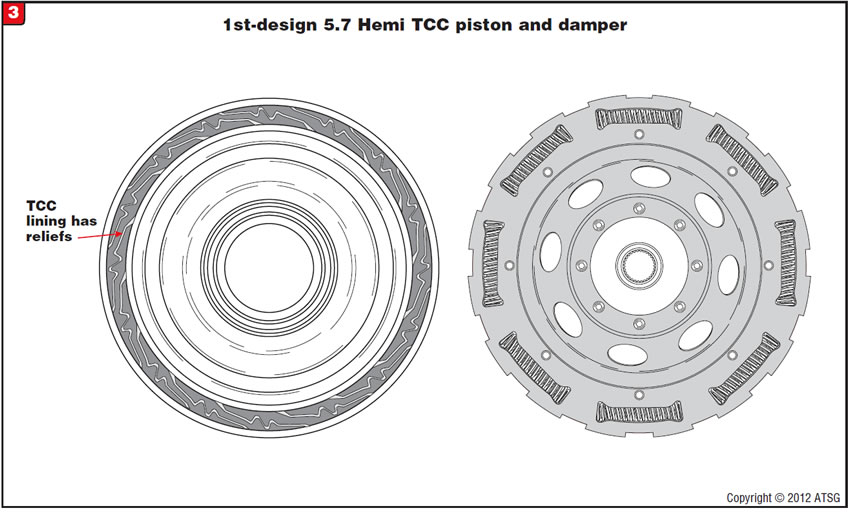

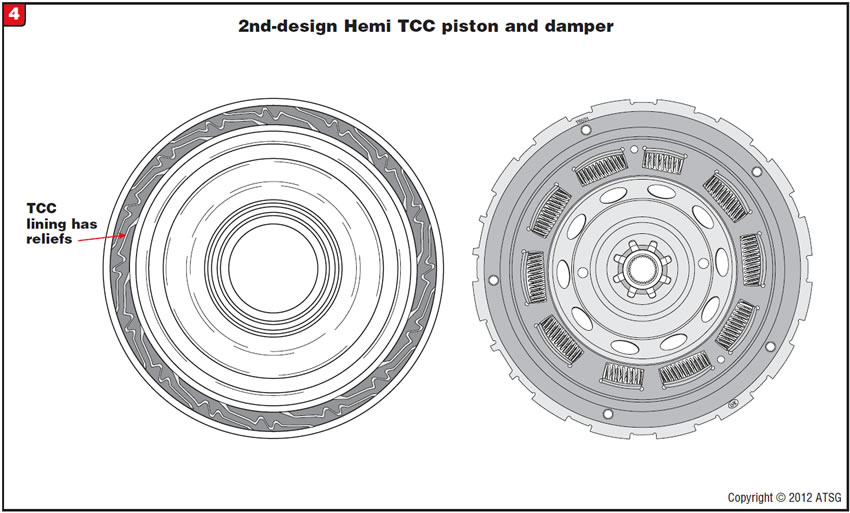

Figures 3 and 4 show the Hemi low-stall TCC lining. Note that there are reliefs through the lining that will help the TCC slip when it is in partial-application mode.

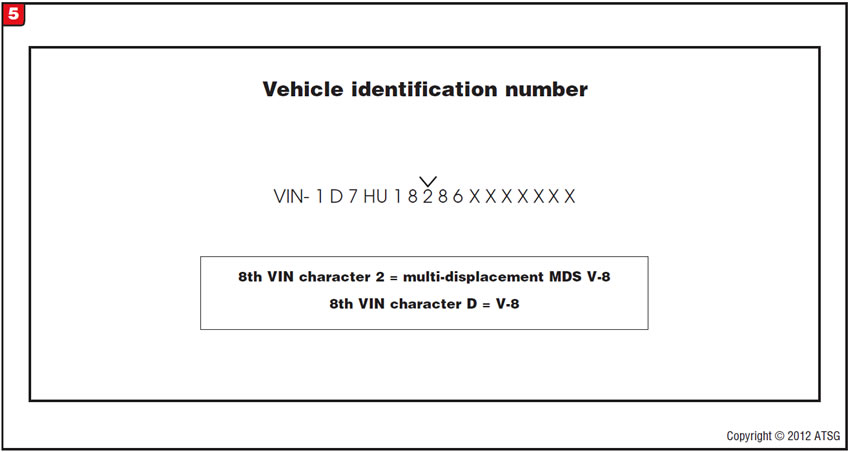

To correct this condition, contact your local torque-converter distributor and use the converter specified for the vehicle that you are working on. Also verify that they are using the OE lining or the “high-carbon lining,” which will interchange. In Figure 5, which explains the vehicle identification number, note that the eighth digit identifies the engine type. D represents a full-time V-8, and 2 identifies the MDS engine.

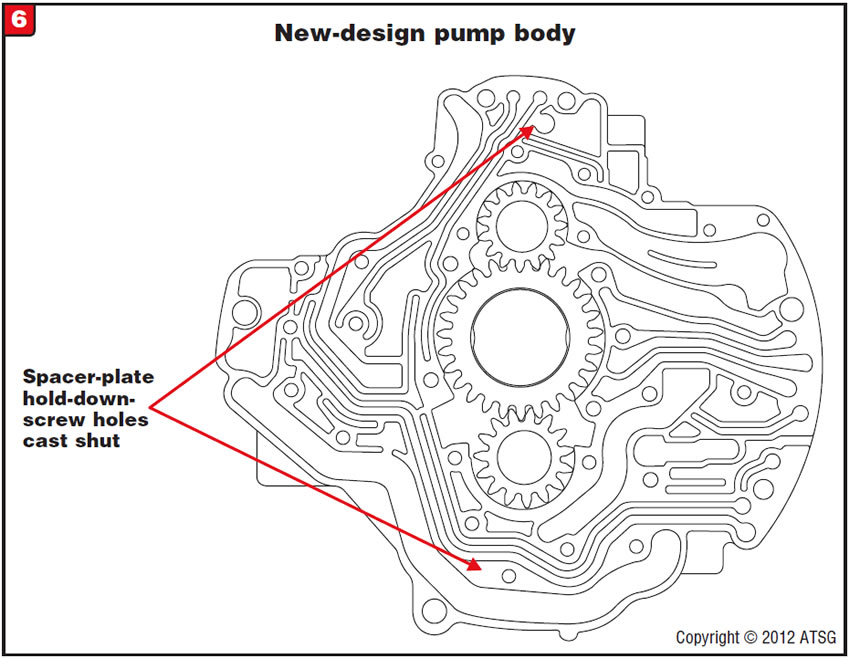

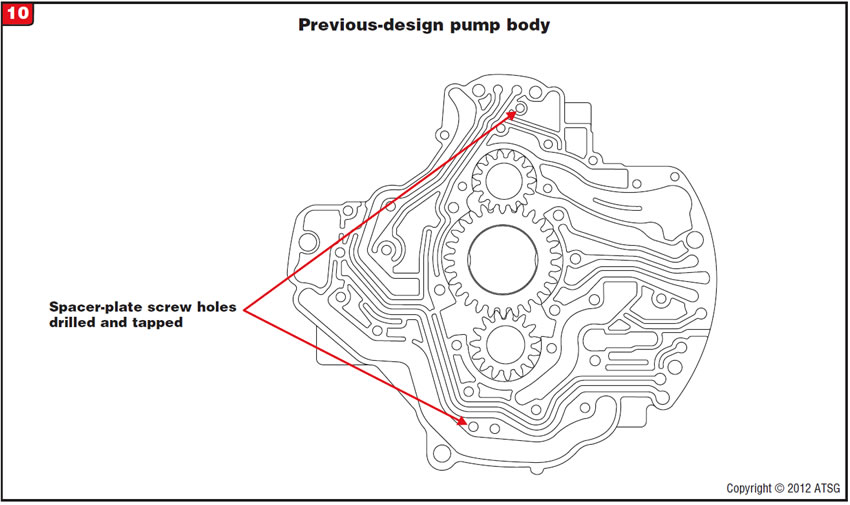

The two screws that held the spacer plate to the pump body have been eliminated and the screw holes have been cast shut (Figure 6).

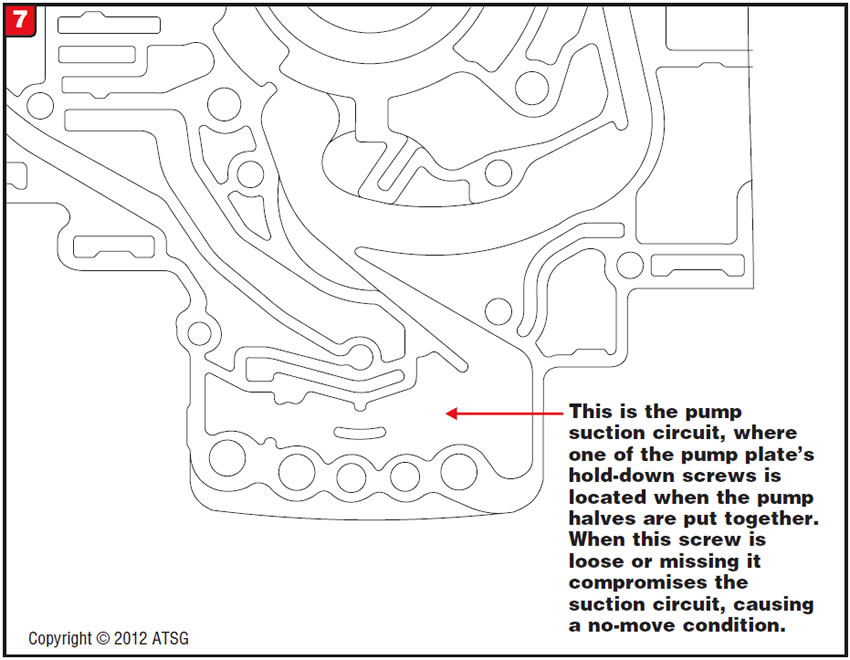

With the spacer-plate-screw holes cast shut, the pump suction passage in the pump cover is sealed and therefore cannot cause a no-move condition. This eliminates the need for the screws (Figure 7).

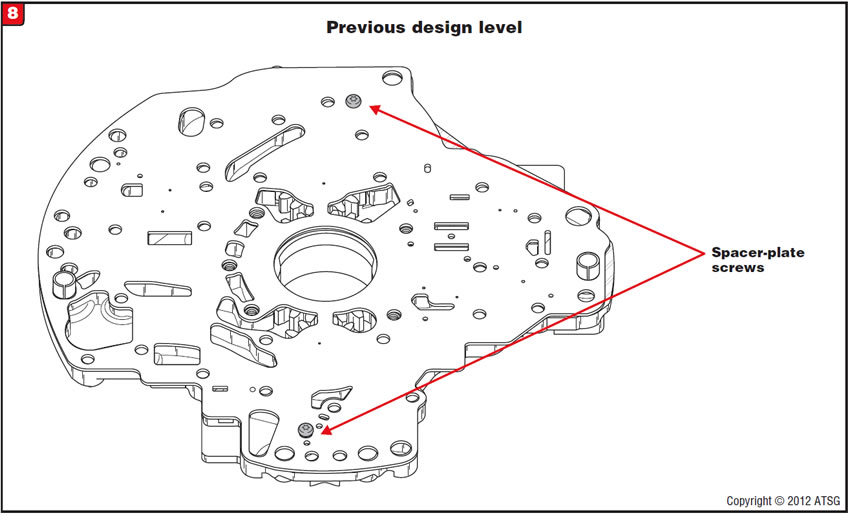

The previous design pump spacer plate has the holes for the screws (Figure 8);

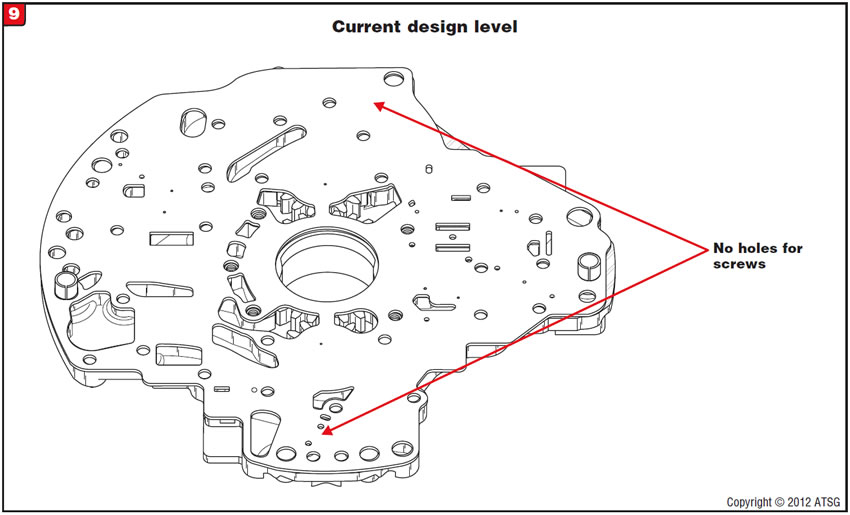

the later-design pump spacer plate has no screw holes (Figure 9).

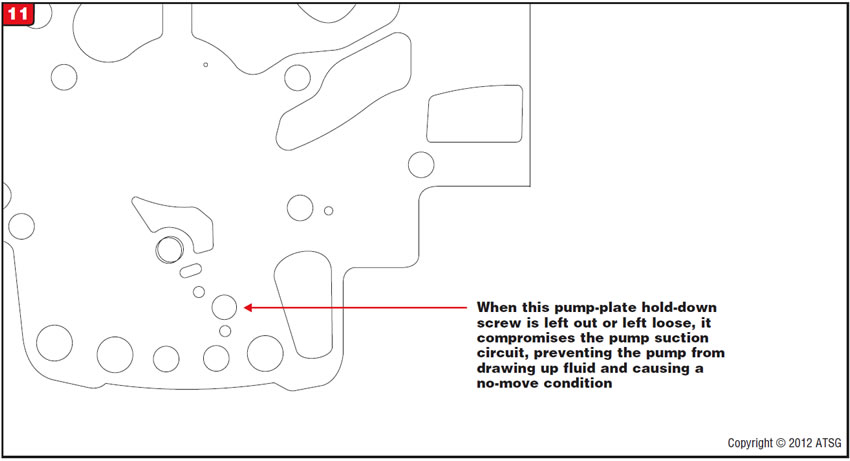

With the previous-design pump, which has the screw holes drilled (Figure 10),

the screws are necessary because those holes exist in the pump suction passage in the pump cover (Figure 11).

If the screws were loose or missing, the pump suction circuit would be significantly compromised, making the pump unable to draw up fluid and resulting in the no-move complaint.

The pump body and spacer plate.

The newly designed pump assembly will back-service all 45/545RFE transmissions.

- New design pump assembly . . . . . . .68009879AD

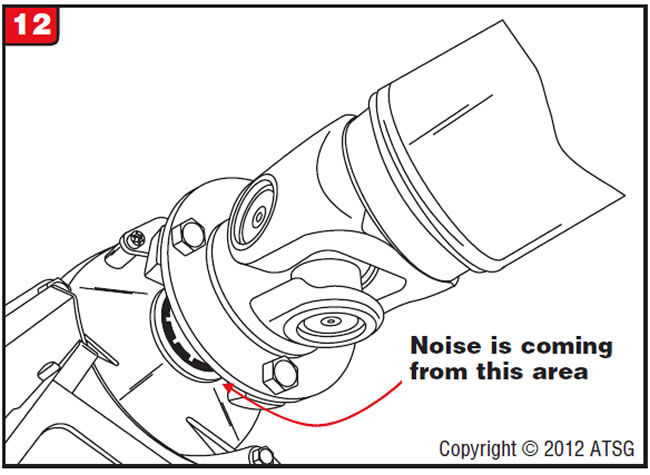

A 2005-07 Dodge Nitro, Magnum or Charger; Chrysler 300; or Jeep Grand Cherokee or Commander may come in with a complaint of a ringing, snapping or popping sound during a garage shift from drive to reverse or from reverse to drive. The technician finds that the noise is coming from the driveshaft (Figure 12).

Spline rub of the output flange to output shaft.

Mark the prop shaft in relation to the differential yoke and remove the prop shaft. Remove the output-shaft nut and use an appropriate puller to remove the output flange. Replace the output-shaft flange if the vehicle you are working on is one of the following:

- 2005 Chrysler 300C with 5.7-liter engine built prior to Aug. 18, 2004.

- 2005 Dodge Magnum with 5.7-liter engine built prior to Aug. 18, 2004.

- 2005 Jeep Grand Cherokee with 3.7-liter engine built prior to June 22, 2005.

- 2006 Chrysler 300C with 3.5-liter engine built prior to June 22, 2005.

- 2006 Dodge Magnum with 3.5-liter engine built prior to June 22, 2005.

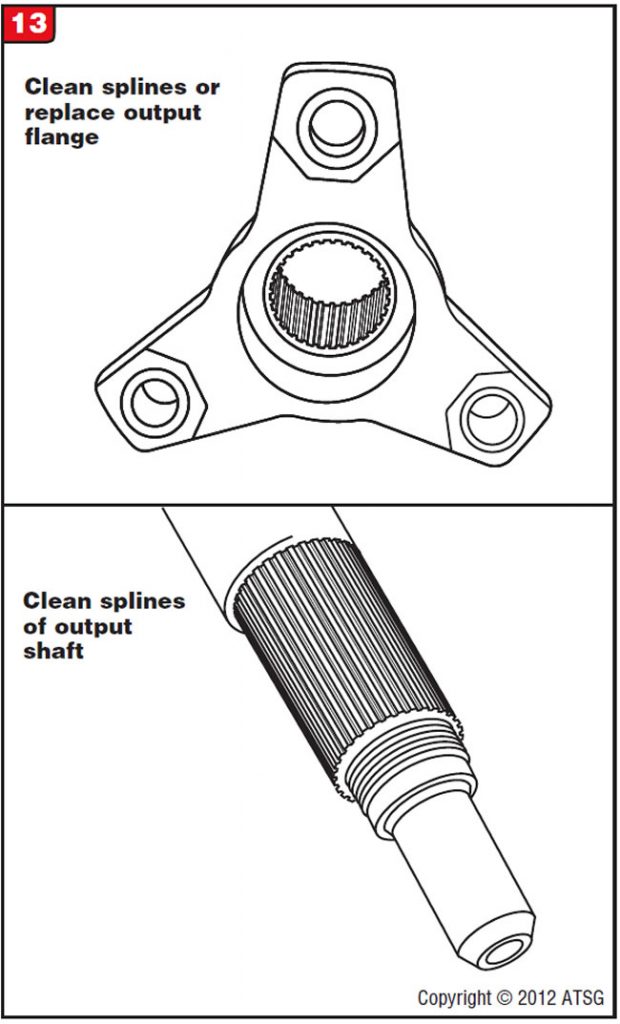

If you are working on a vehicle not listed here, clean the output shaft and the output-flange splines and apply a thin coating of Stud & Bearing adhesive to the splines of the output flange (Figure 13).

Install the flange and nut and tighten the nut to 150 lb.-ft. (200 Nm). Stake the nut in place.

Install the prop shaft, lining up the previously created alignment marks.

- Output flange nut . . . . . . . . . . . . . . . . . . 52108234AA

- Output flange (3.5L). . . . . . . . . . . . . . . . . 05175566AA

- Output flange (3.7L). . . . . . . . . . . . . . . . . 52108628AB

- Output flange (5.7L). . . . . . . . . . . . . . . . . 05135158A

- Output flange (6.1L). . . . . . . . . . . . . . . . . 05170003AB

June 2012 Issue

Volume 29, No. 6

- 2006-up Dodge trucks, 545RFE: TCC shudder and/or poor gas mileage

- Chrysler/Dodge/Jeep 45/545RFE: front-pump change

- Chrysler/Dodge/Jeep NAG 1: garage-shift ringing noise