Issue Summary:

- Some 1997-2002 vehicles equipped with the 4T40-E or 4T45-E transaxle may exhibit harsh engagements and/or harsh upshifts and may have trouble codes PO112, PO113, P1111 and/or P1112.

- Since the introduction of the THM 4T40-E transaxle in 1995, there have been three different design levels of the accumulator springs and their locations.

- Some 2003-model THM 4T65-E transaxles come equipped with a newly designed input and third pawl-clutch assembly instead of the previous-design input and third sprag clutch.

- Beginning in June 2002 Hydra-matic changed the design of the oil-pump assembly on 2002 and 2003 models of the 4T65-E transaxle.

Some 1997-2002 vehicles equipped with the 4T40-E or 4T45-E transaxle may exhibit harsh engagements and/or harsh upshifts and may have trouble codes PO112, PO113, P1111 and/or P1112.

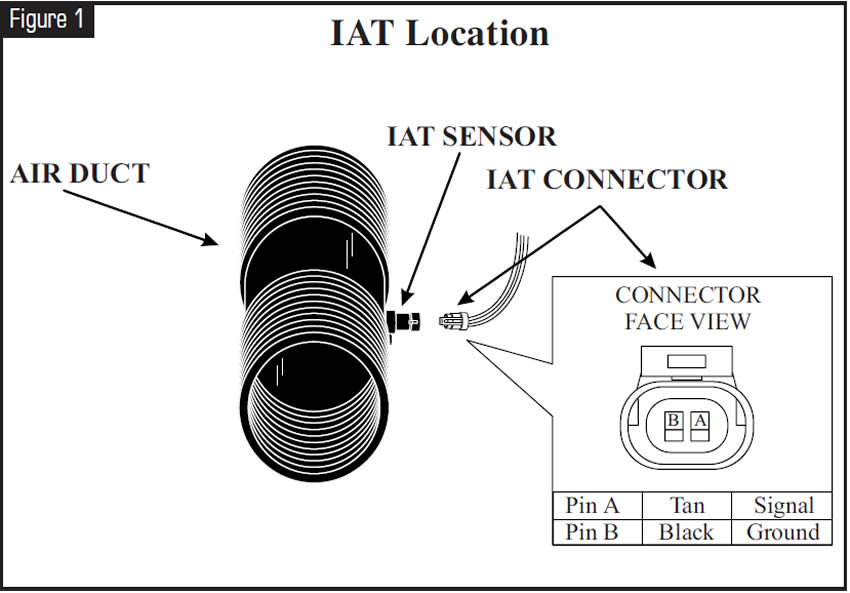

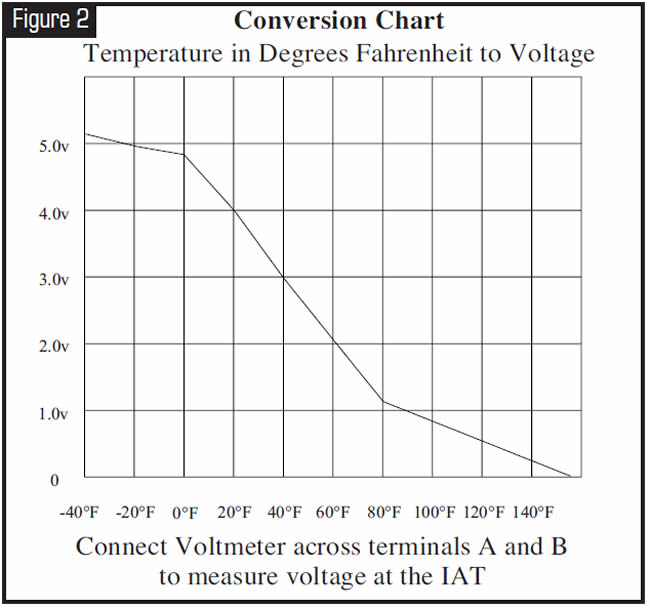

One cause may be a broken ground wire at the connector of the intake-air-temperature (IAT) sensor. The reason for the hard shifts is that computer strategy monitors the IAT sensor for pressure control. When the ground wire to the IAT is open, the powertrain control module receives information from the IAT that the temperature is below -40° F, which causes the PCM to command maximum line pressure.

The IAT sensor is in the air duct between the mass-air-flow sensor and the air cleaner (see Figure 1). The IAT sensor can be checked using the chart in Figure 2. Factory technical-service bulletin # 02-06-03-005.

- Intake-air-temperature-sensor connector repair end. . . . . . 12162199

- Intake-air-temperature sensor . . . . . . . . . 12160244

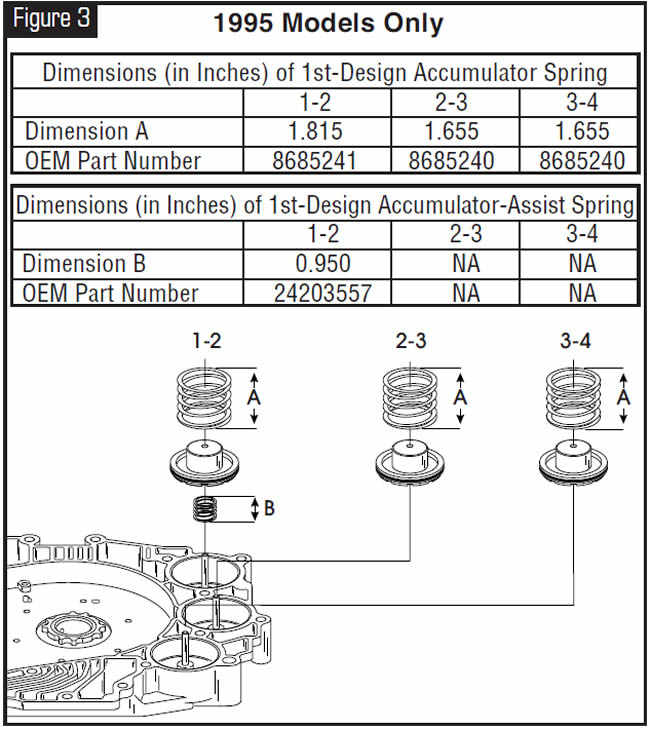

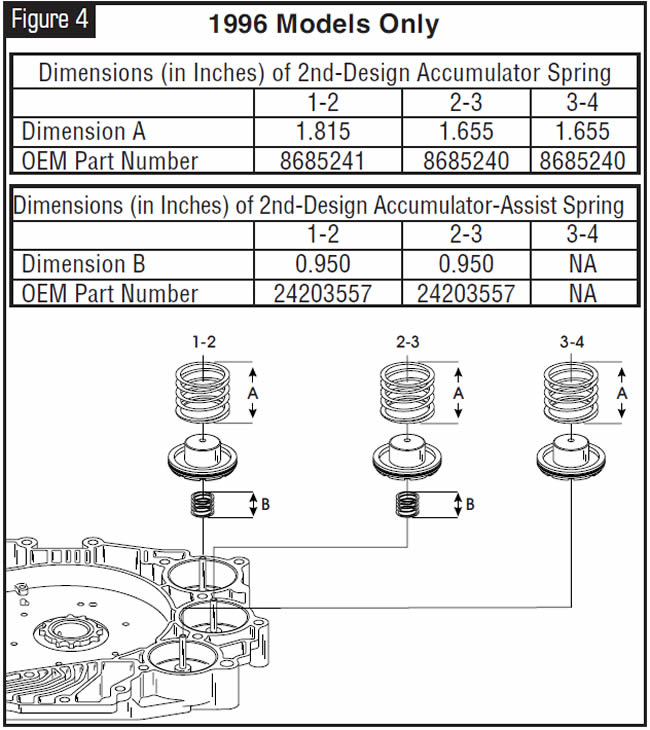

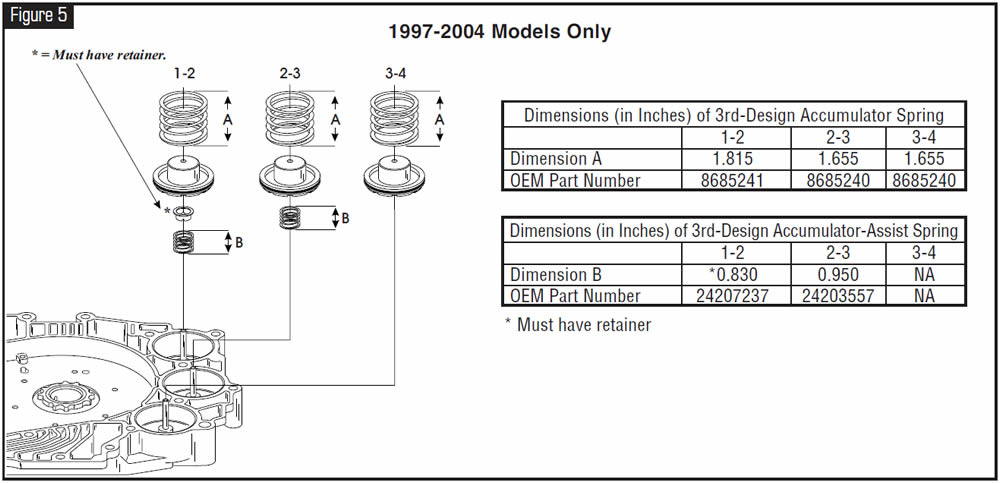

Since the introduction of the THM 4T40-E transaxle in 1995, there have been three different design levels of the accumulator springs and their locations.

Refer to Figure 3 for 1995 models.

Refer to Figure 4 for 1996 models.

Refer to Figure 5 for 1997-2004 models.

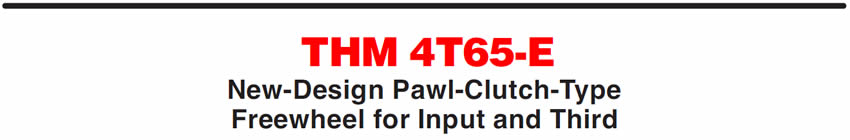

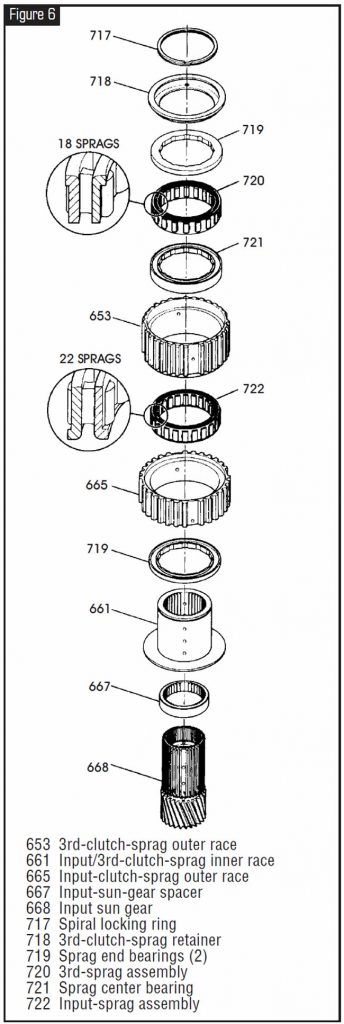

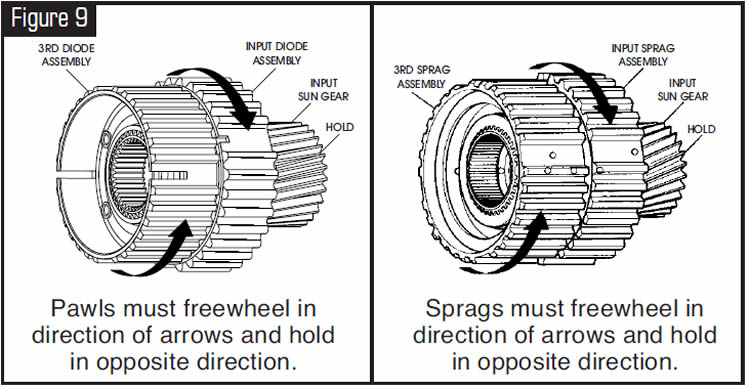

Some 2003-model THM 4T65-E transaxles come equipped with a newly designed input and third pawl-clutch assembly instead of the previous-design input and third sprag clutch (see figures 6 and 7). GM implemented this change at the start of production for the 2003 model year.

Ease of assembly and cost savings.

Input pawl clutch – The new-design outer race has 30 splines instead of the previous 32 on the input sprag. Unlike the previous-design sprag clutch, it cannot be disassembled, which obviously makes the assembly process easier. Refer to figures 6 and 7 for illustrations of both designs.

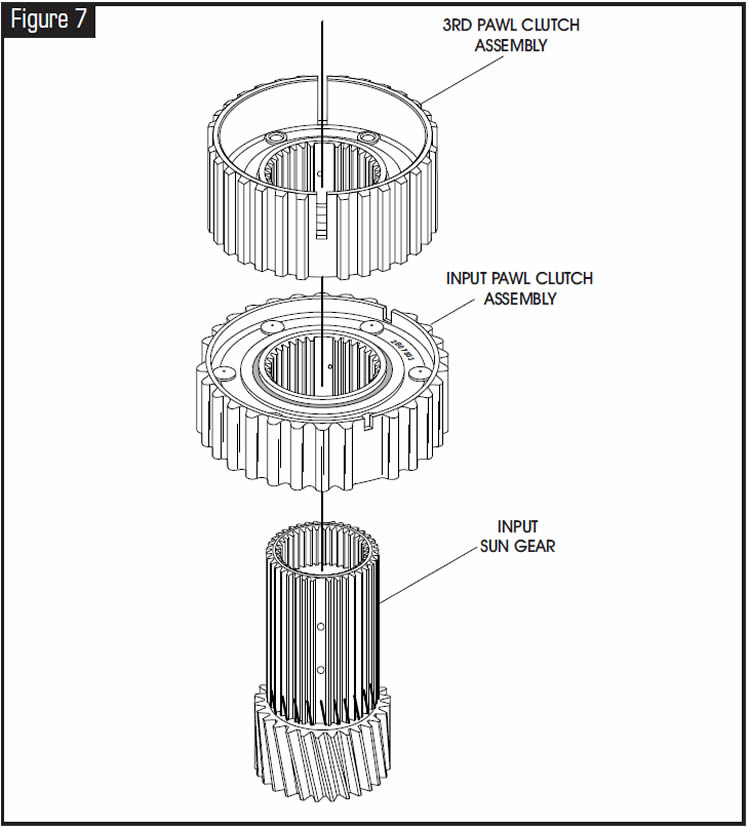

Input-clutch fiber plate – The new-design fiber plate has 30 teeth instead of the previous design’s 32 teeth, to accommodate the new-design pawl-clutch assembly. Refer to Figure 8 for illustrations of both designs.

Third pawl clutch – Unlike the previous-design sprag clutch, the new design cannot be disassembled, which obviously makes the assembly process easier. Refer to Figures 6 and 7 for illustrations of both designs. The third-clutch fiber plates remain the same as in previous models.

The parts listed will back-service any model of 4T65-E transaxle equipped with the previous dual-sprag design when all parts are used as a service package.

Note: To maintain proper operating clearances within the transaxle, these parts must be used as a set. Do not mix these parts with any previous-design assemblies.

BorgWarner OEM

Input pawl-clutch assembly. . . . . . . . . . . . . . . . . . . . 13013BW. . . . . . . . 24216816

Input-clutch friction (mates with pawl clutch) . . . . 29194AM. . . . . . 24216502

Third pawl-clutch assembly. . . . . . . . . . . . . . . . . . . . . . 13000BW. . . . . 24216817

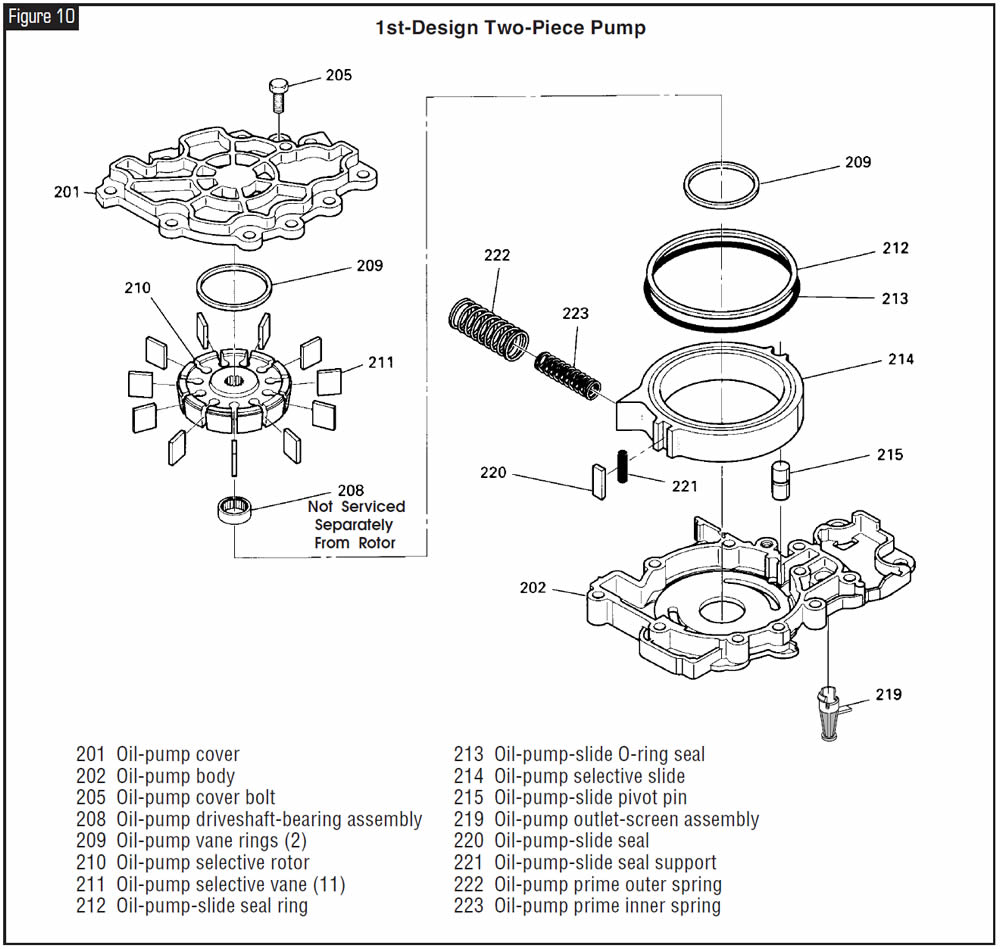

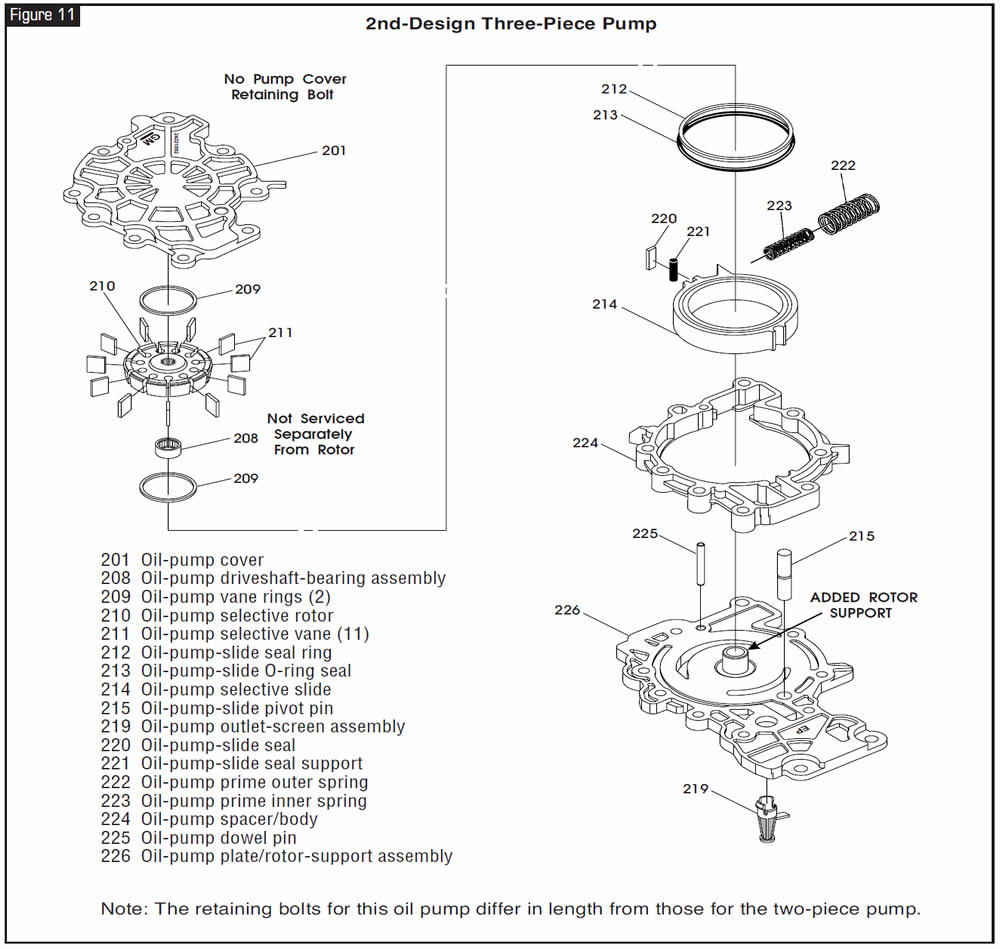

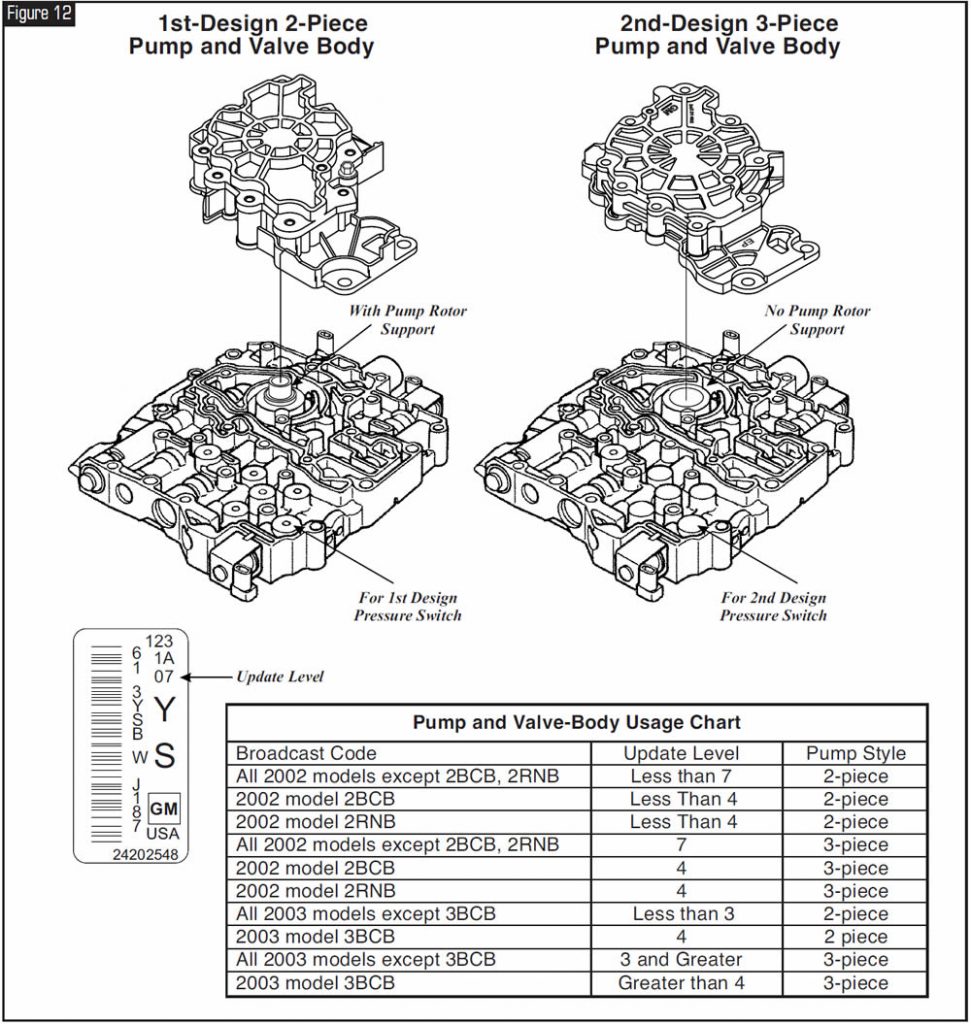

Beginning in June 2002 Hydra-matic changed the design of the oil-pump assembly on 2002 and 2003 models of the 4T65-E transaxle. The pump has been changed from a two-piece design to a three-piece design, which has affected many of the related parts. Figure 10 illustrates the two-piece pump, and Figure 11 illustrates the three-piece design.

A physical inspection of the ID tag will be mandatory, to obtain the update level, before you order components for these transaxles. Refer to Figure 12 for the location of the update level on the ID tag and a usage chart for design level of the pump assembly.

Oil-pump assembly – Changed to a three-piece design, as shown in Figure 11. The three-piece design now incorporates the rotor-support sleeve in the pump instead of the valve body. Figure 10 illustrates the previous-design two-piece pump.

Oil-pump-assembly retaining bolts – Are different in length from the previous-design bolts.

Valve-body assembly – The pump-rotor-support sleeve has been removed from the valve body to accommodate the three-piece pump assembly (see Figure 12).

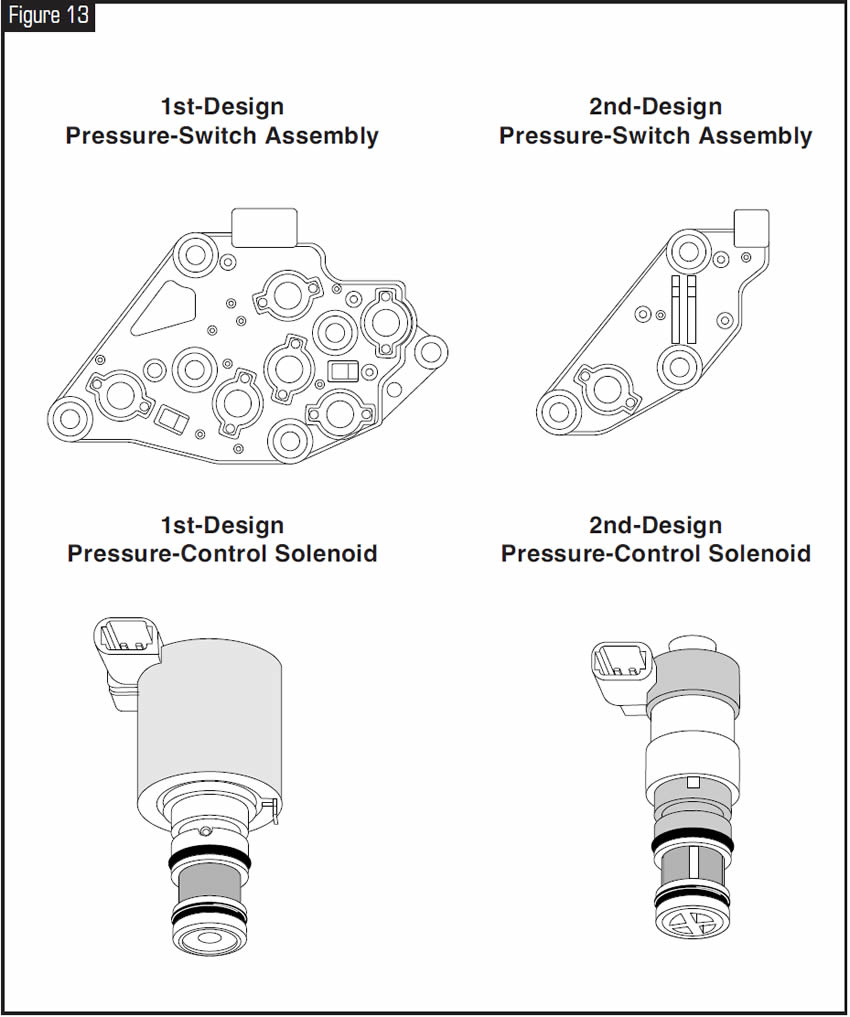

Pressure-switch assembly – Changed to a much smaller assembly with the elimination of all switches except the TCC switch (see Figure 13).

Internal wire-harness assembly – Changed to accommodate the second-design (smaller) pressure-switch assembly.

Pressure-control solenoid – Is much smaller than the previous design (see Figure 13) for improved line-pressure control.

Special Information: Following are the possible combinations that you may encounter.

- Two-piece oil-pump and valve-body assembly with large first-design pressure switch.

- Three-piece oil-pump and valve-body assembly with large first-design pressure switch.

- Two-piece oil-pump and valve-body assembly with small second-design pressure switch.

- Three-piece oil-pump and valve-body assembly with small second-design pressure switch.

None of the parts listed above will interchange with one another. First-design parts must be used together and second-design parts must be used together.

Special Note: The physical dimensions will allow the new pressure-control solenoid to be installed in past models, or the previous pressure-control solenoid to be installed in 2003 models. Interchanging the pressure-control solenoids will result in customer dissatisfaction and additional repairs.

June 2004 Issue

Volume 21, No. 6

- 4T40-E/4T45-E: Harsh Engagements and Upshifts

- THM 4T40-E: Dimensions and Proper Assembly Procedure for 1-2, 2-3 and 3-4 Accumulator Springs

- THM 4T65-E: New-Design Pawl-Clutch-Type Freewheel for Input and Third

- THM 4T65-E: 2002-2003 Oil-Pump Changes