Technically Speaking

- Author: Wayne Colonna, Technical Editor

Exhaust-Brake Operation

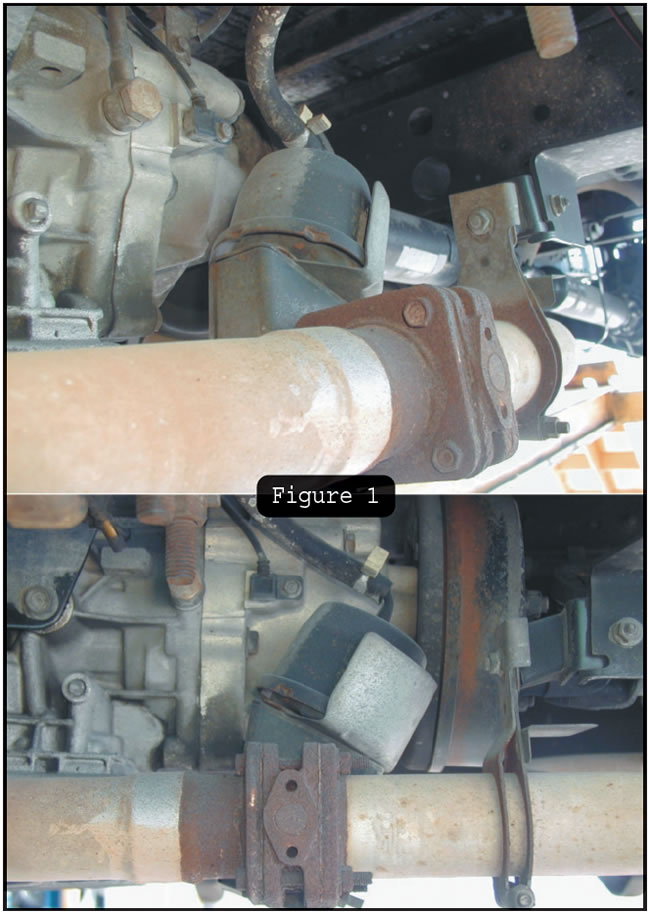

The Isuzu NPR Commercial Truck and GMC Forward Tiltmasters use an exhaust-brake system that assists in engine braking during downhill coasting while the trucks are carrying heavy loads. This system is used instead of the familiar Jacobs Vehicle System known as the “Jake Brake.” When the exhaust brake is activated, it restricts the flow of exhaust with a flapper valve in the exhaust pipe similar to that of a heat-riser assembly (see Figure 1). When the flapper valve closes, exhaust pressure increases, causing air intake to decrease. This increased backpressure and slower air intake reduce torque transfer to the geartrain, producing the desired on-demand engine braking needed during downhill coasting with a payload.

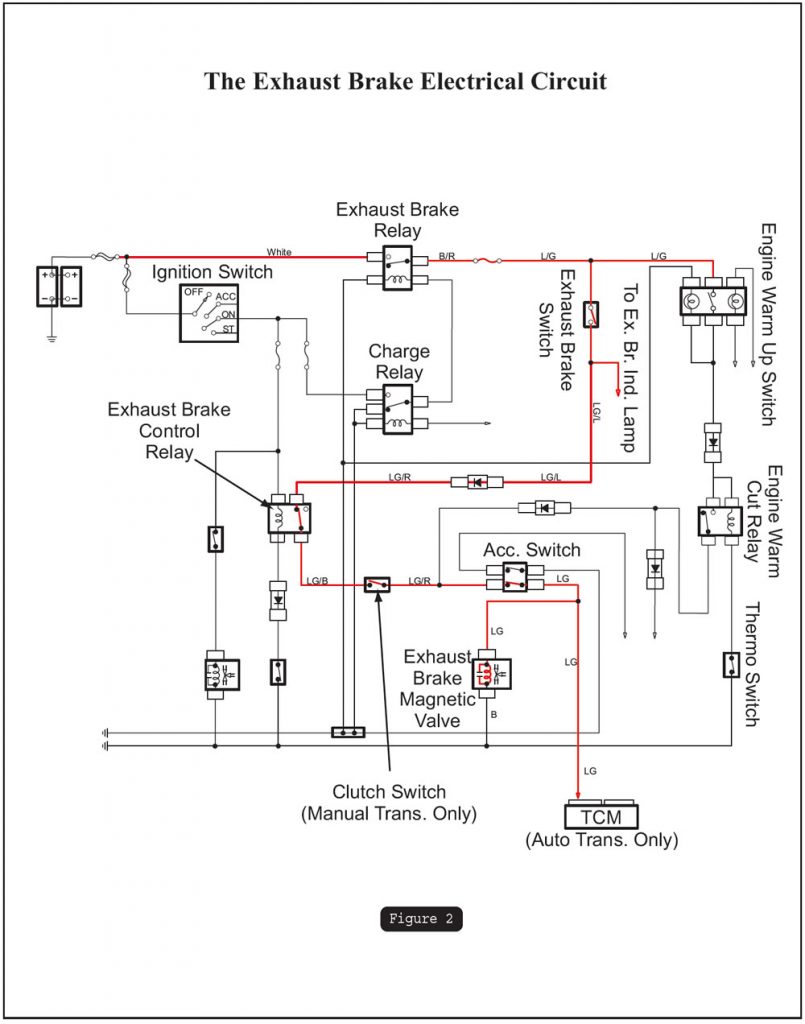

The overall system’s operation is similar in trucks using either a manual or automatic transmission. The difference is that the clutch switch is used in trucks with a manual transmission, and with automatics a signal is sent to the PCM (powertrain control module), as seen in the system wiring diagram in Figure 2. This signal informs the PCM that the driver has requested exhaust-brake operation, and when certain driving conditions are met, the PCM elevates the transmission’s main line pressure. This elevation in line pressure decreases the possibility of the band and various clutches slipping – especially so for the overrun clutches, since they are being used to provide engine braking also.

As designed, this exhaust-brake operation aids in extending the life of not only the brakes but also the transmission. But when this system malfunctions, it can produce various complaints, some of which will affect transmission operation – premature transmission failure, poor engine performance or no engine braking, to name a few.

The exhaust-brake switch is incorporated into the smart arm (see Figure 3). Pulling the arm forward opens and closes the switch. When the vehicle is at operating temperature and the exhaust-brake switch is activated, the same symbol on the smart arm appears in the dash (see Figure 4). This indicates that the exhaust-brake relay, exhaust-brake switch, engine-warm-up switch, engine-warming-cut relay and thermo switch are functioning correctly.

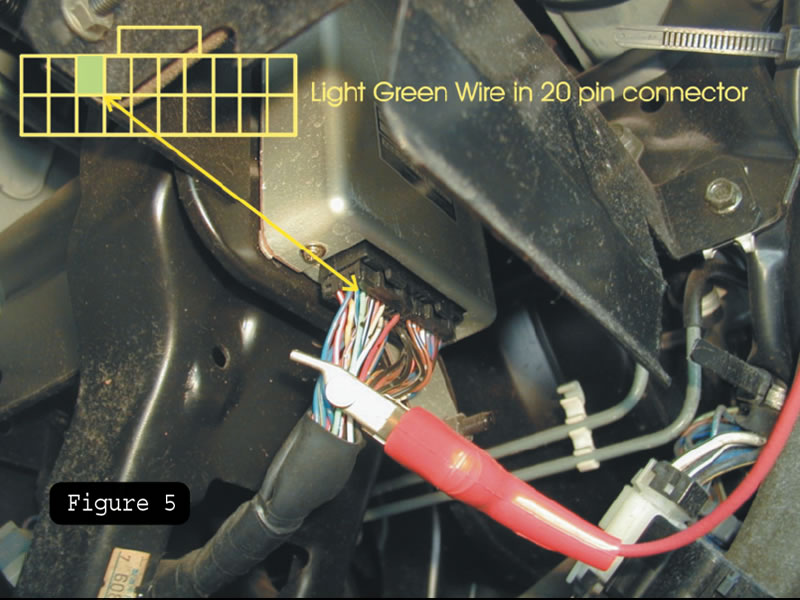

To verify that the signal is being sent to the PCM, probe into the light-green wire in the 20-pin connector (see Figure 5). When the switch is off, you should see no voltage (see Figure 6). When the switch is on, you should see system voltage (see Figure 7). Without this signal, the PCM will not elevate line pressure when needed, causing premature clutch and band failure.

The same light-green wire goes to the exhaust-brake magnetic valve in the frame rail close to the exhaust-brake assembly in the exhaust pipe (see Figure 8). This magnetic valve opens and closes a vacuum supply to the exhaust-brake assembly that opens and closes the flapper valve in the pipe. You should see system voltage here in the same manner as at the PCM.

If you see system voltage on the light-green wire at both the PCM and the exhaust-brake magnetic valve when the exhaust-brake switch is turned on, and no voltage when it is turned off, the entire electrical system has been verified to be functioning properly. If engine braking is still not functioning, the possible causes may be:

- A loss of vacuum supply to the magnetic valve.

- A mechanically failed magnetic valve.

- The flapper valve in the pipe may be seized in the open position.

If the vehicle is experiencing poor engine performance, it is possible that the magnetic valve has failed mechanically and is stuck open or that the flapper valve in the pipe has seized in the closed position.

One other note regarding bad performance: Throttle cables on these units like to stretch beyond adjustment. Sometimes the pedal is halfway to three quarters depressed before the throttle body begins to open. This becomes a problem, as the TPS is on the throttle-pedal bracket. The computer sees medium to full throttle before the vehicle begins to move. This makes for complaints of late and harsh upshifts.

Many thanks to Rolly at Rainbow Transmissions in Hialeah, FL, for letting me into his shop to take these photos and for buying me lunch while I was there!