Up to Standards

- Subject: Electronic diagnosis of GM transfer cases

- Vehicle Application: 2005 Chevrolet Silverado 1500 pickup

- Essential Reading: Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

Are you working on the part of the car that has the problem?

With the steady advance of technology, motor vehicles have become safer, more fuel efficient, less polluting and much more complex. This will continue to make very large demands on the people who work at repairing them and must learn how these systems work and how they relate to each other. Failure to do so will be a career-threatening move.

Every day technicians are faced with complex diagnostic routines to locate the problems causing the customer complaint. It may seem exaggerated to say that without the correct scan tool, and access to OEM repair information, it is now impossible to be successful at transmission repair, but I will win the argument.

Along with meeting the requirements mandated by law to improve fuel economy and reduce automotive emissions, the auto manufacturers have made great advances in vehicle safety. We now have “active” transfer cases, antilock braking systems, traction-control systems and stability-control systems being built into these cars. Computer controls have made all this possible, and the manufacturers are creating these systems to protect the driver from himself, to preserve their customer base.

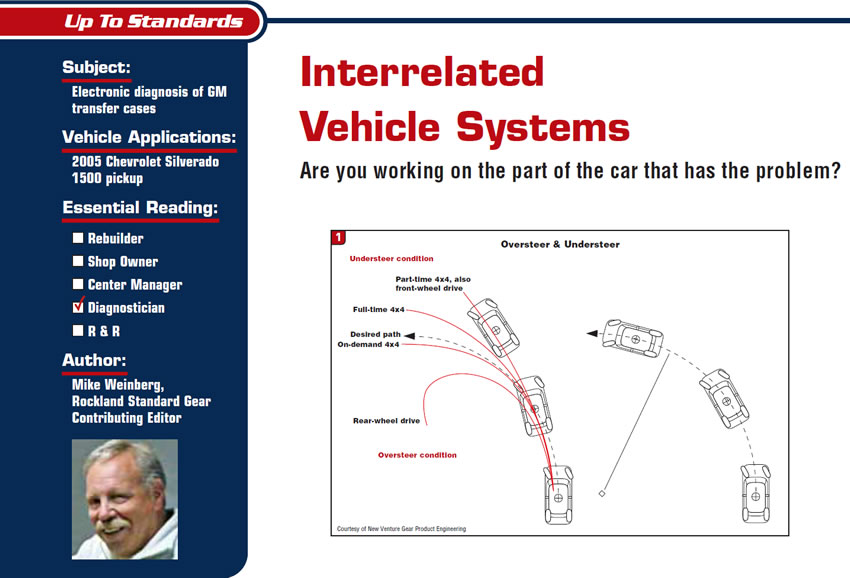

The problem facing our industry is the greater complexity in diagnosing customer complaints to find out where the cause of the problem is. The first step is understanding vehicle dynamics. Most drivers are completely unaware of understeer or oversteer. Understeer – or push, in racing terms – is the inability of the vehicle to turn in at speed because its tendency is to continue in a relatively straight line (see Figure 1). Oversteer – or loose, in racing terms – is the rear of the vehicle wanting to pass the front in a turn.

As Richard Petty was fond of saying “When the car pushes (understeers) you see the crash happen, and when it is loose (oversteer) you don’t.” All cars are built with a slight amount of understeer, which is easier for the average driver to handle. What happens in real life is that a huge number of people on our highways are traveling at high speed, talking on a cell phone, with no idea of vehicle dynamics. You see a big SUV with 4WD flying by in slippery conditions with the driver confused by the fact that having four driving wheels gives them the ability to get to speed but it’s still difficult to stop or make a turn without spinning out.

Enter the factory designers with computer controls to prevent disaster and help keep the vehicle on its intended path despite the loose nut behind the steering wheel. First came ABS, which modulates fluid pressure to each wheel brake so that the wheel can turn without locking up and producing a skid. Then came intelligent transfer cases, which send torque to the wheels that need it to prevent unintended off-road excursions. Later came traction control, which helps control a driver with a heavy right foot by applying the transfer case, braking at individual wheels to prevent loss of traction due to too much power, and selectively limiting firing on certain engine cylinders to slow forward motion until wheel speeds are equalized and traction is maintained. Stability control changes body-roll rates through the shock absorbers, generally to keep the entire tread surface of all the tires planted on the roadway.

All these systems are related by serial data between various computers, and what seems like a transfer-case problem may be an ABS problem. Now the understanding of how these systems work together is your only path to making a repair and working on the correct parts of the vehicle, the first time.

For purposes of this discussion we’re looking at a 2005 GM Silverado 1500 pickup. Ford, Dodge and other manufacturers have similar systems, and we have room to deal with only one of them. The theory, however, is the same for all makes, and by understanding the theory you can easily read up on a specific manufacturer’s system.

The GM design features a PCM (power control module), an electronic brake-control module (EBCM), a traction-control switch (TCS), wheel-speed sensors (WSS) and an instrument cluster that has both ABS and TCS lights. As the front wheels rotate, the wheel-speed sensors create an AC signal. The EBCM calculates front-wheel speed from that signal, which the PCM converts into a signal of 128K pulses per mile. The EBCM uses the vehicle-speed signal from the PCM to measure rear-wheel speed.

It should be obvious that any differences in tire size or tire air pressures can cause incorrect readings and miscommunication between the two computers. This will immediately ruin your diagnostic day, so make sure that you measure all tires with a stagger gauge and make sure all tire pressures are correct before proceeding further. The diagnostic trouble code (DTC) for this problem is C0238, “Wheel Speed Mismatch.” When the code sets, the EBCM disables the ABS and TCS, the ABS indicator turns on, the Traction Off indicator turns on and a red brake warning indicator turns on. The problem is that these symptoms can be present without setting a DTC.

Another set of issues comes from a difference of WSS readings even though the tires are OK. If you are lucky you will see DTC CO245, “Wheel Speed Sensor Frequency Error.” This will occur if one or more of the sensors has a signal frequency 15% higher or lower than that of the other sensors. The problem is that the conditions for setting the code must be present for a total of three minutes during a single ignition-on cycle. The symptoms can occur without setting a hard code.

One of the most-common tech calls we get is created by a difference in WSS readings, and you must be aware of the following: The customer complaint will be that after the vehicle slows on dry pavement the ABS actuates. Traction control may come on for no apparent reason, and the truck will feel as if the transfer case has bound up as the vehicle is coming out of a turn. The shudder is usually dramatic, and then the engine will show a loss of power due to activation of the traction control. The tires are fine.

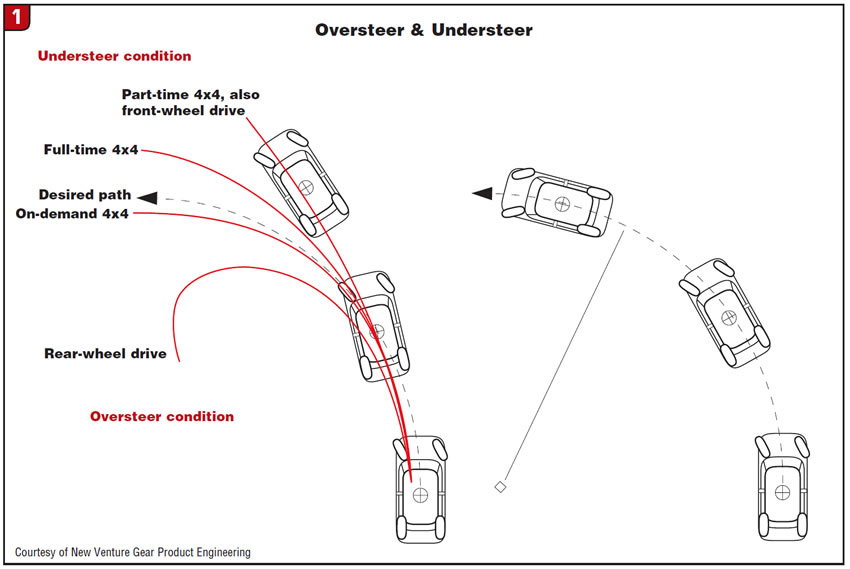

If you measure the signal from each individual speed sensor up front you will see a disparity, but the problem is not in the actual sensor. Unbolt and remove each of the front speed sensors, which are in the hub/bearing assembly (see Figure 2). Look for corrosion built up under the WSS. What happens is that the buildup of corrosion raises the sensor’s position relative to the tone wheel. This creates a larger air gap between the tone wheel and the reluctor and results in false readings.

The good thing is that you can sand off the corrosion, being careful not to contaminate the bearing with foreign matter, and reposition the WSS with the correct air gap, and the problem should be solved. This will happen with AWD transfer cases, leading you to believe the problem may be in the transfer-case clutch pack. Many times technicians remove and disassemble transfer cases only to find that they are AWD with no clutch pack, or if the unit has a clutch pack everything is fine inside.

We always pay for our education, one way or another. Reading is an investment in time and yourself; taking the wrong things apart is a loss of billable time, lost opportunity costs (you could be working on something else for money) and a downer for shop morale.

Knowing how these systems work together should make a few things obvious before trouble hits. If a customer has a GM vehicle equipped with these systems and has changed tire and wheel sizes, or has changed differential ratios, you need to tell the EBCM about this. Every time the ignition is turned on the EBCM gets a signal giving it the stock wheel size and differential ratios. If either or both of those have changed, the computer needs to be reprogrammed with those changes by a scan tool or else you will be trying to solve an impossible problem.

The guy who sold your customer the new wheels and tires or the shop that changed the differential ratios may not have reprogrammed the EBCM. Assumption is the mother of all screw-ups. Get into the computers and verify that all information is correct for what is on the vehicle. Ask the customer the right questions to help you solve the problem.

There is collectively about 125 pages of technical information involving the diagnosis of ABS and TCS, and dozens of DTCs. We do not have the space here for a complete discussion. The object here is to get you thinking about interrelated systems, and get you interested in learning the theory of how they work and how to make the correct diagnosis to ring the cash register every time. Ignorance is not bliss; it is expensive and dangerous to your reputation and job security. These systems are complicated but are easy to understand, and ignorance will drive the butchers back to the meat market where they belong.