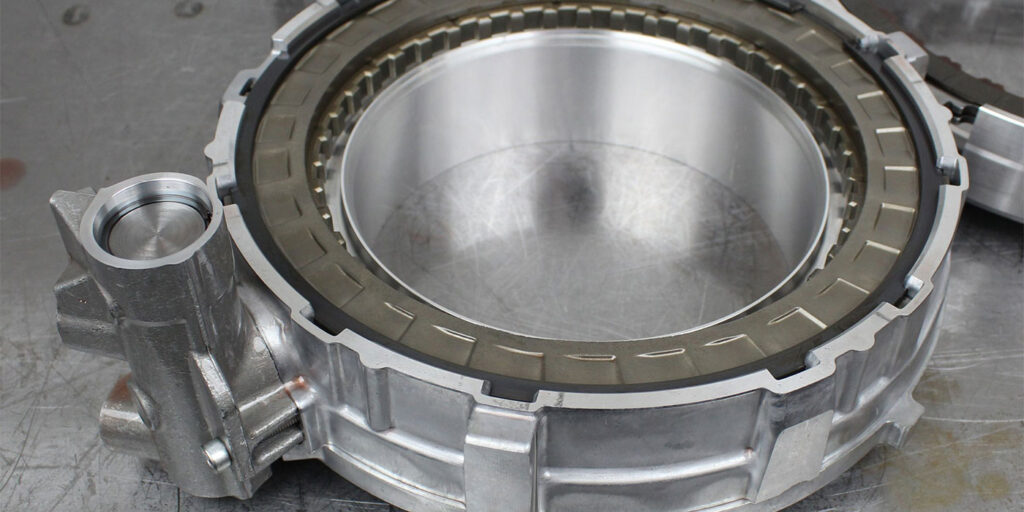

A Hydraulic Selectable One-Way Clutch (SOWC) is used in GM’s 9T50 (figure 1, above) and Ford’s 8F35 transmission (figure 2, below).

Its function and design are quite clever. The center plate inside this selectable one-way clutch lugs to the Overdrive Carrier. On the top side of this center plate are spring-loaded struts. Integral to the cover plate (which lugs to the housing), are one-way cam notches. These ramped style notches are designed so that the struts in the center plate can lock into it in one direction while allowing it to freewheel in the opposite direction (see figures 3, 4 and 5). Its basic construction is that of a mechanical diode.

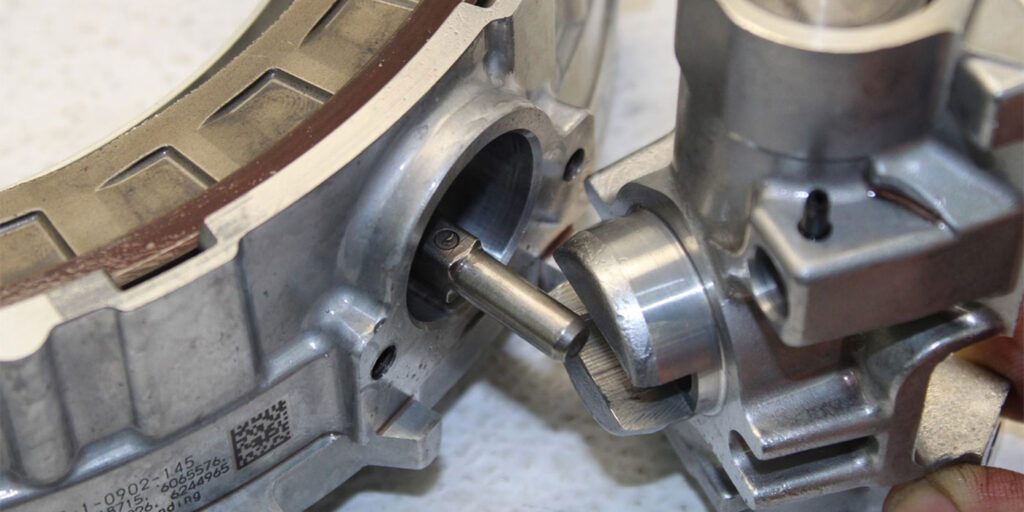

You will also notice that mounted on the side of this assembly is the SOWC hydraulic piston that is used to move a lever (see figure 6). This lever operates a sheet metal window which, in one direction, will hold down an additional set of spring-loaded struts. When the lever is hydraulically moved in the opposite direction, these spring-loaded struts will pop up. When this occurs, these struts will lock into the bottom side of the center plate which also has one-way cam notches. When these bottom struts engage the center plate, along with the top struts engaging the center plate, the center plate which lugs to the Overdrive Carrier is locked from moving in either direction.

When the lever is positioned to disengage the bottom struts from locking the center plate, the upper struts lock the center plate from rotating in a counterclockwise direction, but do allow it to rotate clockwise. This is the mode of operation this SOWC needs to be in for a first gear launch; the typical operation of all low one-way clutch devices. Once the transmission shifts out of first gear, the center plate can rotate in a clockwise direction.

For reverse, the lever is hydraulically moved so that it engages the bottom struts, preventing the center plate from moving clockwise while the upper struts prevent the center plate from moving counterclockwise. In other words, it is locked from moving in either direction, functioning like a low/reverse brake clutch.

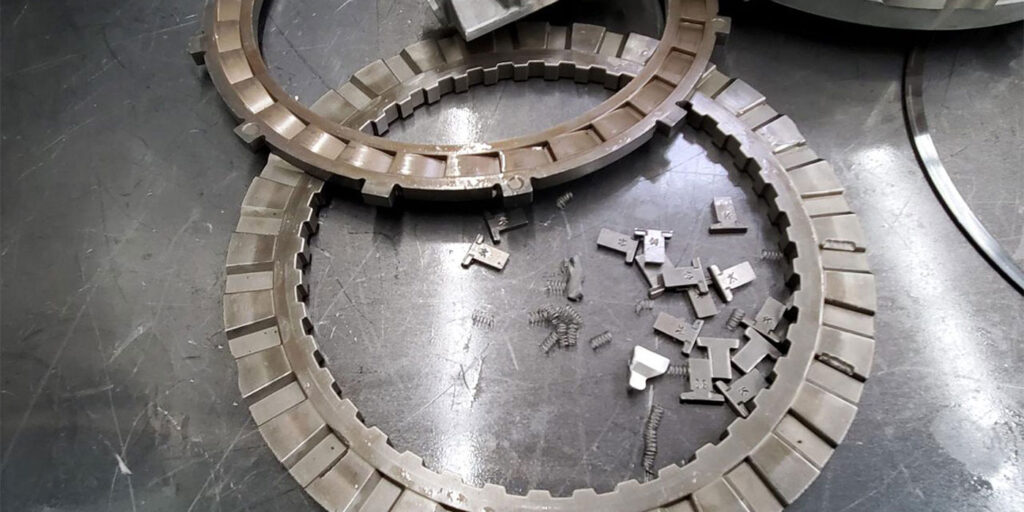

There have been occasions when this SOWC does not work as designed, which you can see by looking at figures 7 and 8. The bottom side of the center plate has gouge marks in the cam made by the spring-loaded struts. You can also see chunks of aluminum which broke away from the housing.

This suggests several possibilities. A rolling engagement into reverse is the most common cause. Another cause occurs after backing up: When drive is selected, the SOWC lever remains in a reverse position. When a shift is made into second gear, a harsh bind up occurs as the overdrive carrier is unable to rotate in a clockwise direction. Or, worse yet, a hydraulic fault occurred while driving forward, causing the lever to move and engaging the bottom struts into the center plate. This would be the scariest and most dangerous scenario of all—but thankfully as of now there has been no report of such a failure.

Ford uses SSD via a SOWC Limit, turning this solenoid on in Park in anticipation that Reverse will be selected. It keeps this solenoid on in Neutral as well for the same reason. Once Drive is selected, pressure is supplied to the release side of the piston to ensure that the center plate does not remain locked from turning clockwise.

With this lever already engaged for reverse in Park or Neutral, when Reverse is selected, only the 4-6-R clutch needs to apply. And this is done via a latch valve to assist in a smooth engagement.

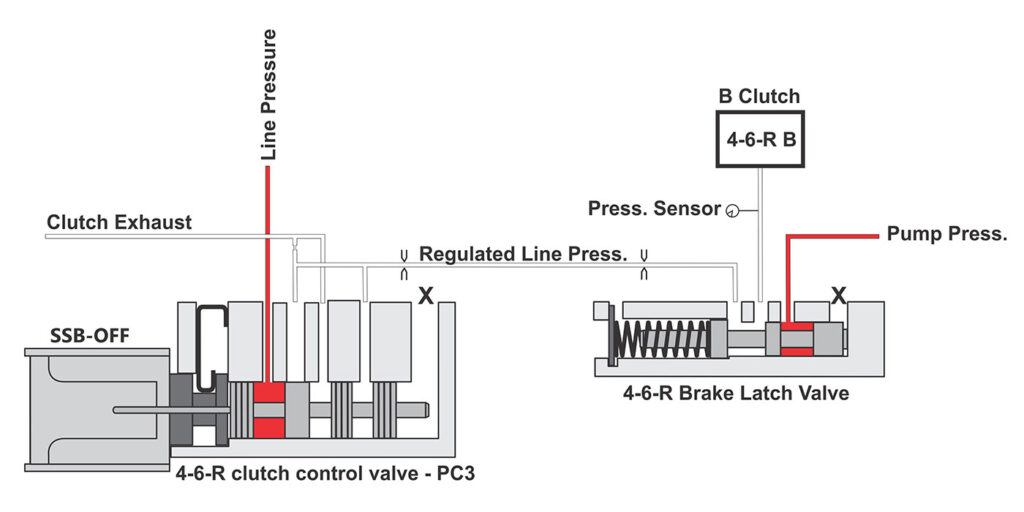

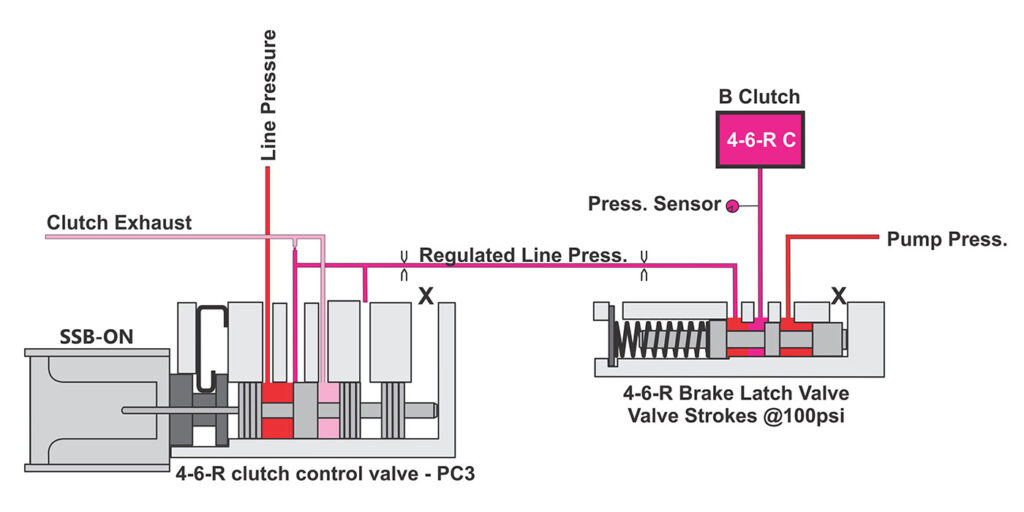

Figure 9 shows that the shift solenoid B is off:

Figure 10 shows what it looks like when this solenoid turns on, sending pressure to the latch valve and the clutch:

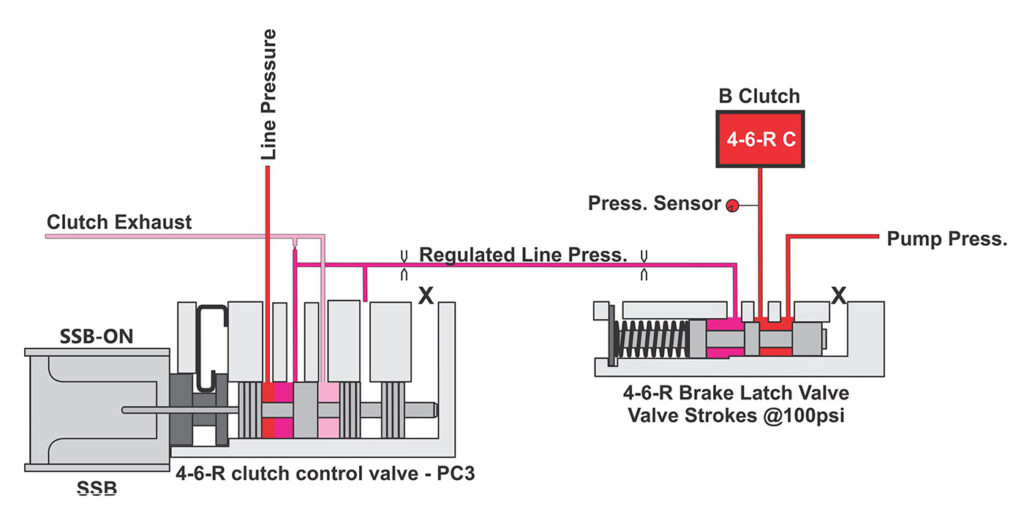

Once 100 PSI is achieved in this circuit, the latch valve strokes, and full pump pressure is supplied to hold the clutch on (figure 11). This progressive application provides a smooth engagement into gear.

Similarly, GM engages this hydraulic SOWC piston in reverse using Solenoid F (1 Rev/6-7-8-9). When this solenoid is off, it provides engagement pressure to the SOWC piston via the clutch select control valve which is stroked by the clutch select control valve solenoid. This solenoid is on in Park, Neutral, and first through fifth gears and then turns back off for sixth through ninth. A feed limit valve provides pressure on the release side of the hydraulic SOWC piston to ensure that the center plates will rotate in a clockwise direction.

So, when Reverse is selected on the GM transmission, two actions take place: Solenoid F turns off to engage the hydraulic SOWC piston, while solenoid E turns on to apply the 5-7-R clutch via a Reverse Clutch Boost Valve. This boost valve is designed to provide a smooth engagement of the 5-7-R clutch ending with full pressure apply on the clutch.

In summary, this cleverly designed SOWC provides both a typical low one-way clutch for a first gear launch while also becoming a Low/Reverse Brake for Reverse. This strut-based one-way clutch mechanism helps improve fuel economy by way of reduced drag torque, lowered mass and improved packaging.

Read more stories from our Technically Speaking columns here.