Up to Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Mistake-free repairs

- Issues: Questions, answers, facts, accuracy

Repairing, rebuilding and remanufacturing a transmission require many levels of skill. Proper diagnosis, adequate road testing and close, in-depth inspection are all required to ascertain what is not working and what needs to be fixed. All of this starts with INFORMATION. The information process begins with the repair order (RO). Year, make, model, mileage, engine type and size, transmission, transfer case, rear end, Vehicle Identification Number, production date component ID tags, shift patterns (especially on transfer cases) and tire sizes are all basic, required information that should be put on the RO. Guesswork of any kind is a no-no. As in any human endeavor – business, sports, social life – he who makes the least mistakes wins. Being properly prepared with every scrap of information that may be necessary to complete a repair successfully the first time, with a minimum of wasted time, is the only acceptable path to profit.

In the past, once a unit was removed from the vehicle and taken apart, the builder would usually order the necessary parts to complete the job. This has changed to some degree, with many parts orders coming from the center manager or front man, so the builder can work without distraction. Many times, if the necessary information is not available to the man making the parts order, there will be a lot of wasted time, incorrect parts ordered, money wasted on freight, and a delayed payment from the customer to the shop. I have been doing this for more than a half a century and have made or seen every screwup possible. There is only one path to righteousness, and that is to be prepared.

There are endless varieties of manual transmissions, transfer cases and rear ends. When you call your supplier to place an order, it is your responsibility to have every bit of information at your fingertips to avoid wasting your time and the supplier’s to get it right the FIRST time. The person on the phone will ask questions to absolutely identify what you are working on so that they can get you what you really need, right away. The questions asked are to complete the cycle of information so that everyone is happy with the outcome.

Your supplier is not asking you for bearing numbers, tooth counts, shift patterns, etc. because they have nothing better to do, and if you are dealing with a vendor who does not ask the appropriate questions you will soon be looking for one who does, because the order fill will be right only part of the time. You should have all of the pertinent information in front of you before you pick up the phone to make the call. Consider it the same as a menu in a restaurant. Sure the waiter will have some questions such as how you want your steak cooked, but you are reading from an information sheet that gives you what your available choices are. Would you try to order dinner without ever looking at the menu? I am sure you could but the waiter (supplier) will spend a lot of time trying to get you provide information he needs to please you and get your meal right and right away.

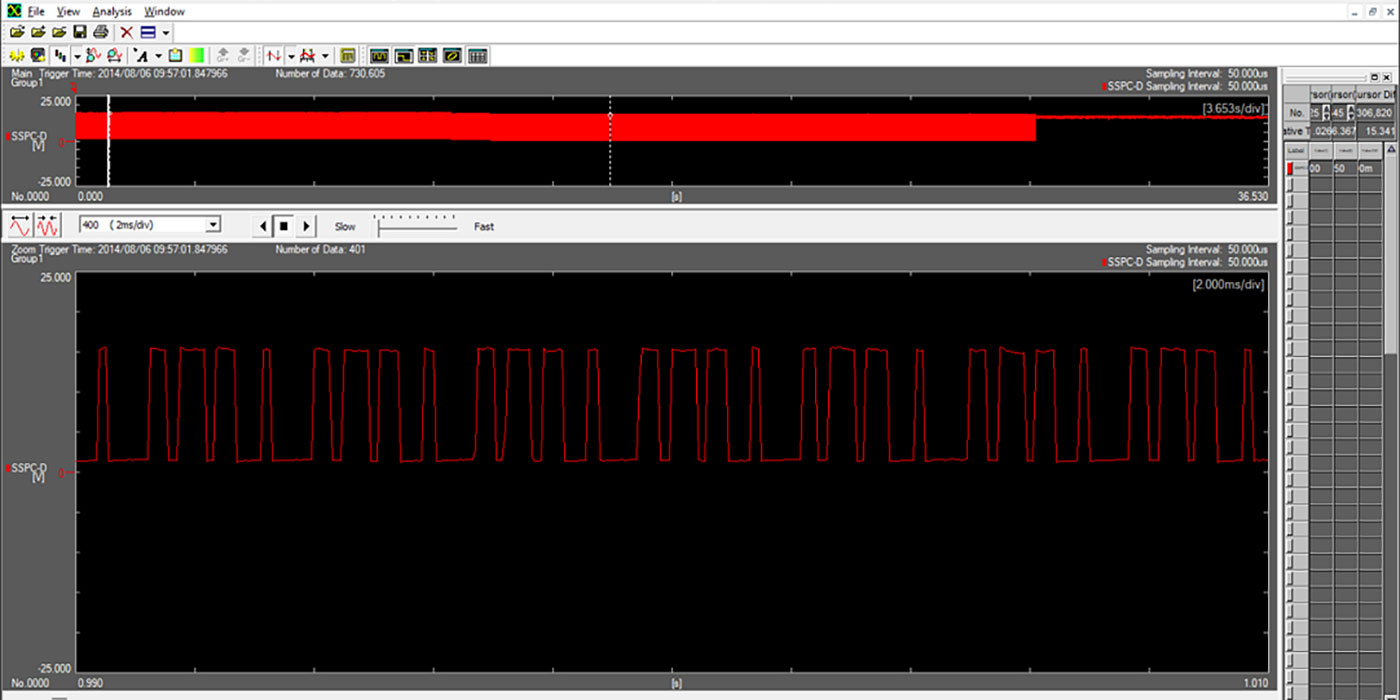

“They ask too many questions” is a common complaint. Did you not ask your customer many questions to identify the complaint, understand the problem thoroughly, and identify with what the customer wants? Did the diagnostic guy road-test the vehicle and through the process seek answers to many questions regarding codes, operating temperatures, battery voltage, tire sizes and pressures, engine management issues, ABS, stability control, P codes, U codes, and an endless quest to find out how and where the problem of concern shows up? When the unit was torn down for internal inspection was it not thoroughly cleaned and every part questioned through inspection before a parts list was drawn up?

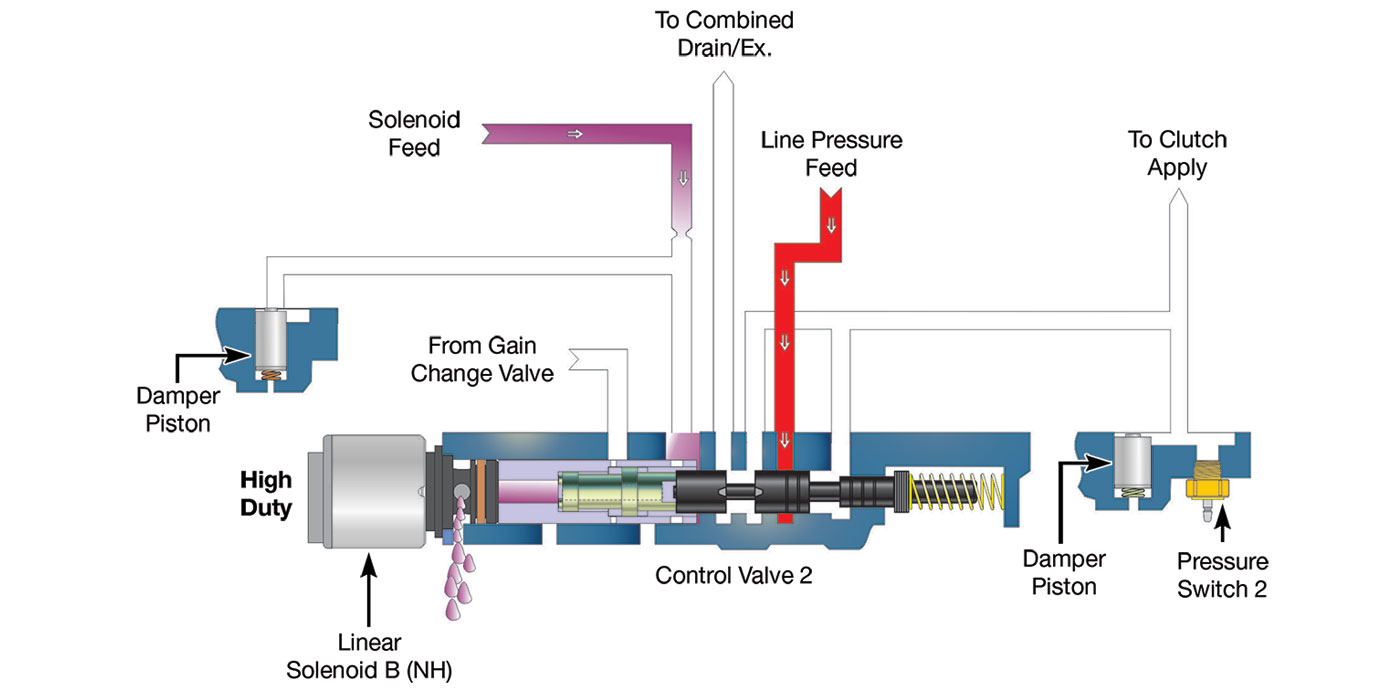

If you hold yourself out to be a professional, it is your responsibility to ask all the questions to obtain every necessary piece of information to solve a very complex problem. Careful note-taking and proper paperwork give you the keys to the kingdom of INFORMATION. There is no one-size-fits-all answer. The manufacturers make constant changes to improve their product and eliminate as much cost under warranty as possible. This means that in any model year there may be multiple internal changes in the unit, where without the correct information, success is impossible. Has someone been into the unit before you? This should be an instant red flag to make sure you have very bit of information, as you are now in limbo as to who did what, and what parts were used or replaced. The short period of your time that is required to have all the correct documentation will pay you back with large dividends in time and freight saved, along with your reputation as a business. It is said that we live in an information age. At no point in my lifetime has the public been able to access more information through a computer or smart phone. They are used to instant gratification, being able to access vast quantities of info in minutes. This is a double-edged sword that cuts both ways. They want it yesterday and for free, and they are unwilling to put the work in to really understand the issues involved. Nobody wants to push themselves away from the table and work out physically to lose weight and get into shape. They want to buy a pill that will work miracles with no effort involved.

You and I both know that there are no shortcuts to achieve a desired goal. Success comes only by using the common sense that you were born with, hard work, and the never-ending learning curve it takes to be qualified as a technician. The only way to succeed is to have all of the information available to you and to use it. Answer the questions asked from your supplier right away because you have already invested the time to get the information and put it to good use, thereby insuring you are getting the RIGHT parts the FIRST time – which increases your ability to generate the profit margin necessary to stay in business and gave a good life. There is no other way to do this.

Mike Weinberg is president of Rockland Standard Gear.