Technically Speaking

- Subject: Theory and principles of operation

- Unit: GM 6L80

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

The other day I had an interesting conversation with Bob Augustine from Vetronix Corp. in which he reminded me of the day when good old carburetors were being replaced with fuel injection. And you would hear technicians say, “I’m only a carburetor guy; I’m not going to work on any car with fuel injectors.” This made me think of how often I hear transmission technicians say they will never work on imports. The term “import” is becoming increasingly difficult to define.

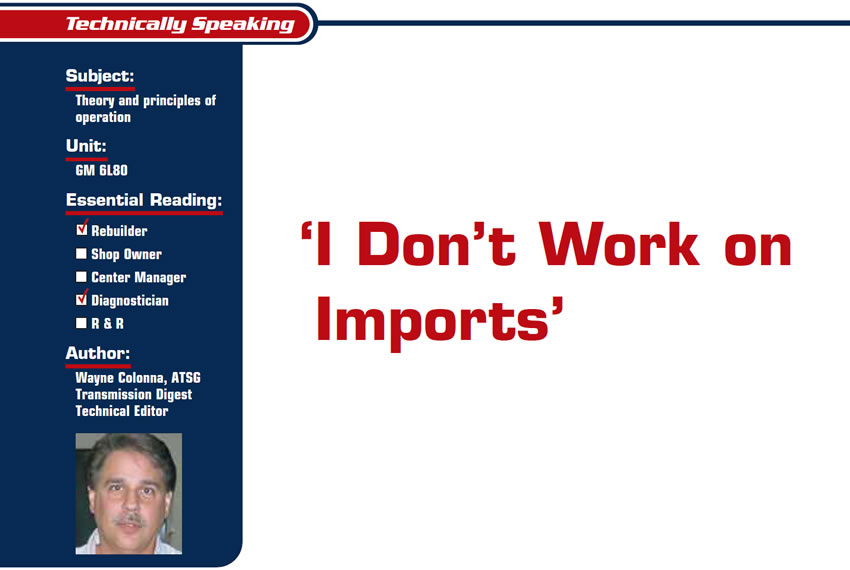

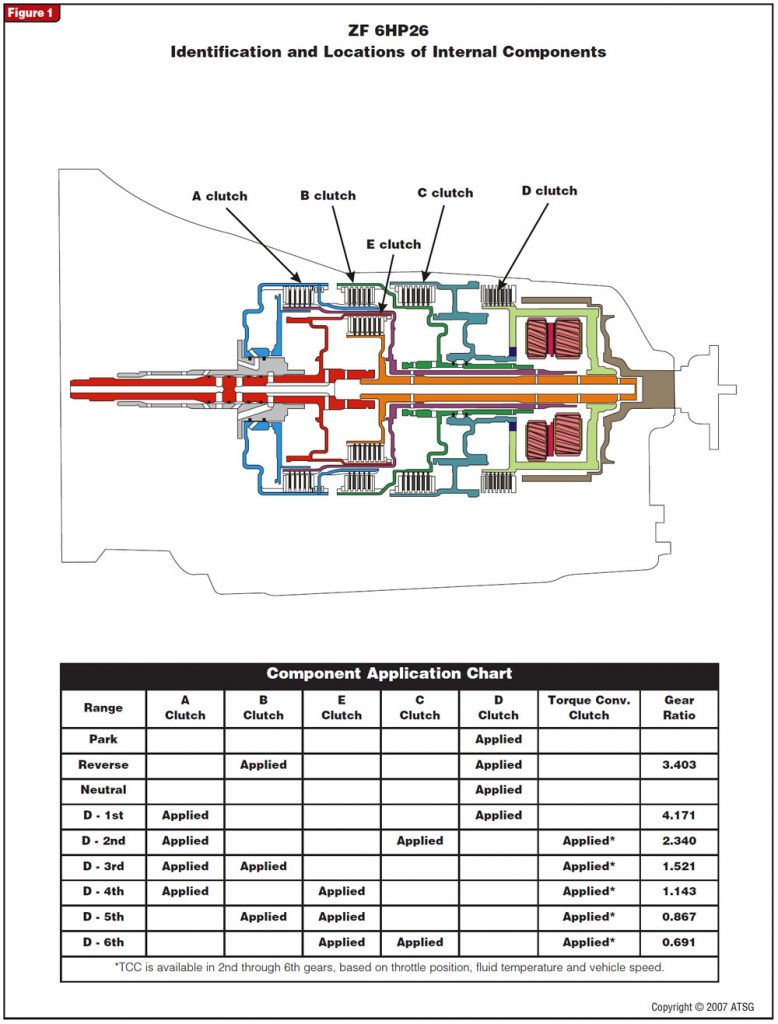

The Shift Pointers article in this issue by Niel Speetjens, an ATSG technical field adviser, is a good example of what I am talking about. Niel’s article gives us a brief introduction to ZF’s rear-wheel-drive six-speed automatics. For those of you who may not be aware of this, GM’s 6L80 has the exact same clutch application and geartrain design as the ZF 6HP. The parts are different, but as you can see in figures 1 and 2 the clutch locations and applications are quite similar.

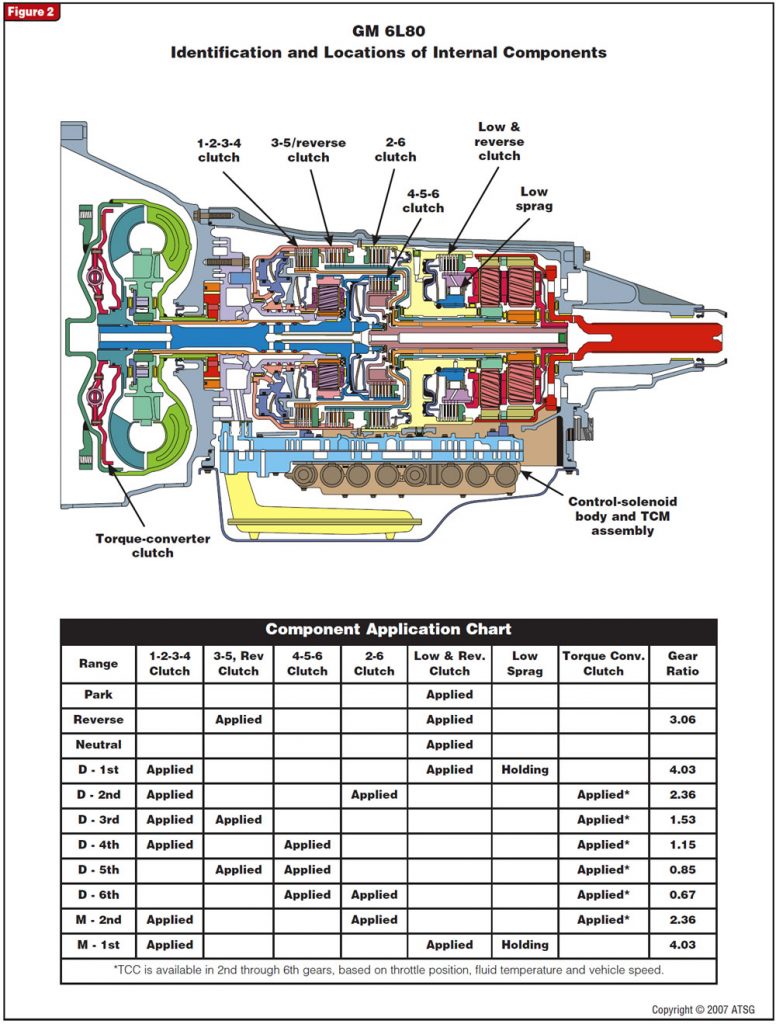

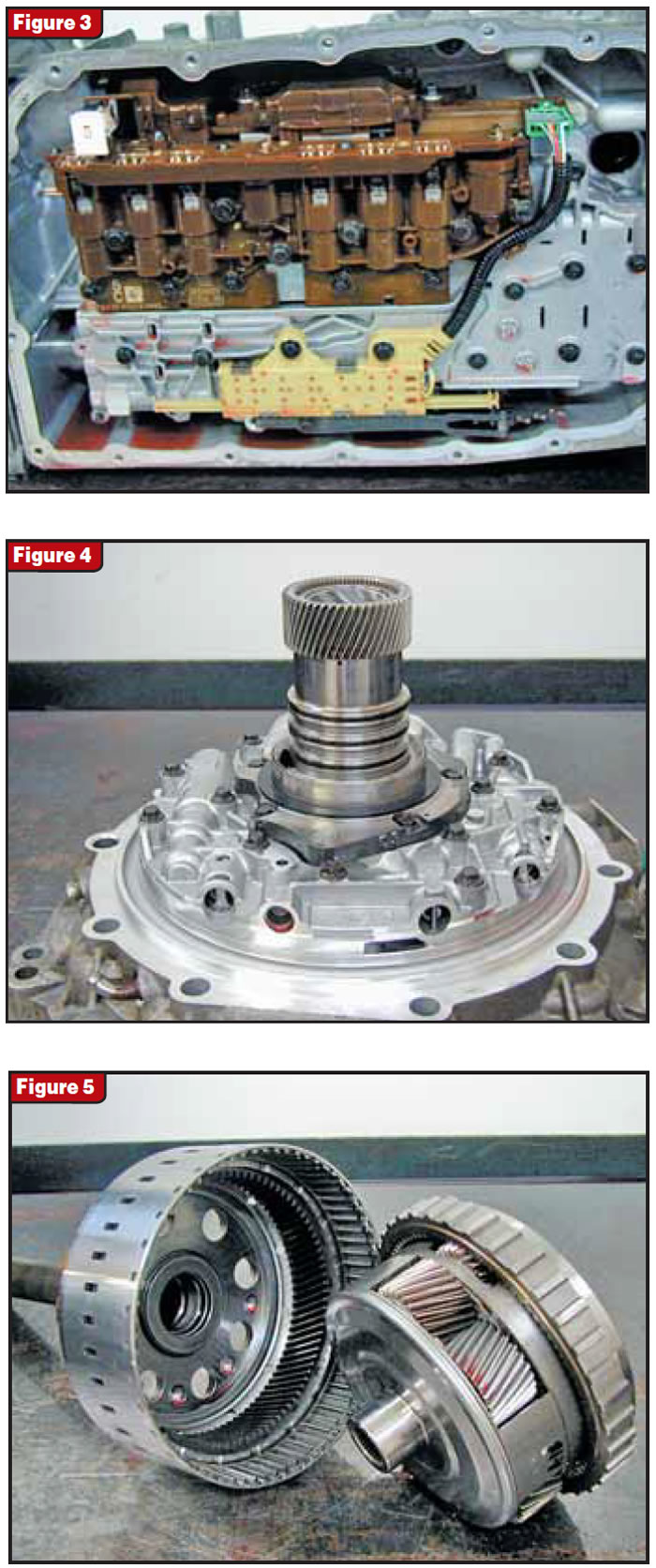

Both units have the TCM and electronics mounted on the valve body (see Figure 3). The pump holds the front sun gear stationary (see Figure 4), just like in the ZF 6HP, and when you see the rear-planetary assembly, it’s obvious that both GM and ZF are using the Lepelletier gear train (see Figure 5).

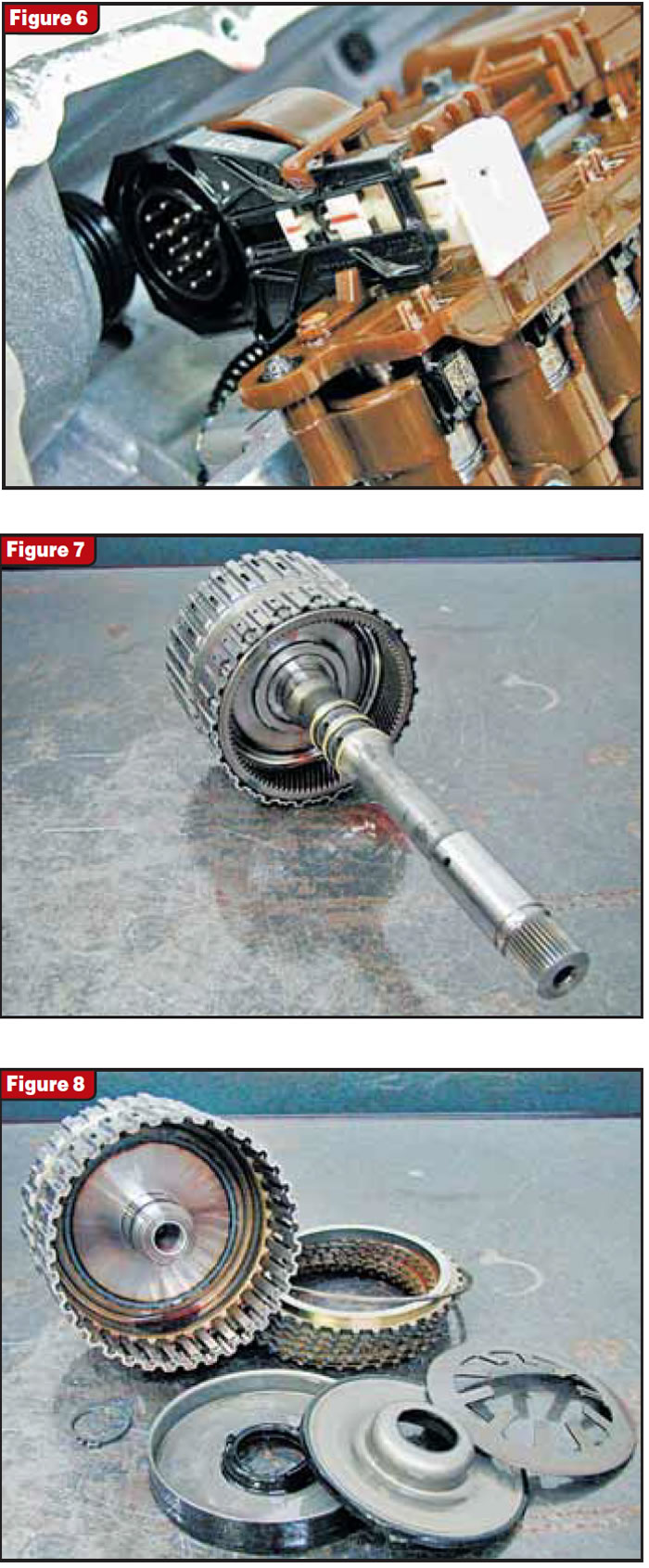

Other similarities between these two units include a locking tab used in both units to secure the electrical connector to the case sleeve. You must release this tab (see Figure 6) before you can remove the TCM/valve-body assembly from the transmission. The turbine shaft is an integral part of the 1-2/3-4 clutch drum in the GM version and the A-clutch drum in the ZF unit. The internal ring gear also is integral to the drum (see Figure 7). This is what drives the front pinions around the stationary sun gear on the pump. The front carrier drives the 1-2/3-4 (or A) and 3-5/reverse (or B) drum. When the 1-2/3-4 (A) clutch applies it drives the rear sun gear in the rear-planetary assembly. When the 3-5/reverse (B) clutch applies, it drives the front (middle) sun gear in the rear-planetary assembly.

One more similarity between these two transmissions, one that I find quite interesting, is what GM calls the “Compensator Feed Fluid” circuit and BMW, using the ZF 6HP unit, refers to as “Dynamic Pressure Balance.” Notice in figures 8 and 9 that the 1-2/3-4 (A)-clutch drum has a double piston. The bottom piston is the one used to apply the clutch. The piston that fits inside the bottom piston is used to retain compensator feed pressure. This pressure counteracts centrifugal force that could cause the clutch to partially apply when it should be released, preventing premature failure of the clutch.

This is the same thinking behind using the 3-4 load-relief springs in the 4L60-E transmission. They prevent centrifugal force from applying the 3-4 clutch in 1st and 2nd gears. But the 6L80 and the ZF 6HP employ this strategy by using hydraulic pressure in all three driving clutches: the A, B and C (BMW) and the 1-2/3-4, 3-5/reverse and 4-5-6 (GM) clutch-piston assemblies. Since the other two clutch packs are not rotating assemblies, there is no need for this strategy. BMW does claim that with the clutch assemblies using this “Dynamic Pressure Balance” system (A, B and C), the computer has greater control over the apply and release of the clutch during their engagements and disengagements, making for a smoother transition. I would imagine this would be the same for GM’s 6L80 transmission.

GM’s 6L80 Technician’s Guide provides a detailed hydraulic presentation of all the circuits, including the Compensator Feed Fluid circuit to each of the three clutch-piston assemblies. In this guide you learn that there is a valve in the valve body called none other than the Compensator Feed Regulator Valve. This valve is fed line pressure, then regulates it down to an unspecified pressure to provide a constant feed to each of these clutch-piston assemblies. I wonder what will happen when this valve sticks or when the spring weakens.

So what’s going to happen to the transmission technician who is determined not to work on imports when a Chevrolet Corvette or a BMW 750i comes into the shop needing transmission work?