Up to Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Real-world experience

- Issues: Noises, parts and more

More Real World Experience

No one wants to have comebacks or waste time with difficult diagnostic issues, but in the long term they are truly educational.

This third article in a series explores real world problems and fixes. This material is based on a huge volume of technical calls and field fixes that we live through in the course of doing business.

Every unit that you repair or rebuild that goes in the car and never comes back under warranty is profitable and an indication of the quality of your workmanship, but you didn’t learn much about the unit. The ones that never leave the lift, or come back in short order, will be your first experience in really learning everything about that unit. Every once in a while you get one that will need to have a zipper on it because it has been in and out of the car so much, and when you finally solve the problem, you will know more about that unit and its operation than the engineer who designed it.

Time is a great equalizer, as no one on earth has any more than 24 hours in a day. Time constraints and expediency will force a shop to change multiple items at once to get a job out the door. If the fix works, there is a sigh of relief, but you did not discover the actual problem with a shotgun approach. The correct learning experience would be to change one thing at a time until you find the key. The extra labor and time is worth knowing for sure which of the components cured the issue, but there is a point at which you need to reunite the customer with his vehicle.

Noises

We get a great many calls about noise complaints. These are by nature a difficult fix, as you cannot see a noise. One interesting trend in these calls is how many times the shop has not checked the fluids. One of the first noise issues is what component is causing the noise, and is it migrating from one area to another and sending the technician in the wrong direction?

Manual transmissions, transfer cases and rear ends don’t have a great deal of oil in them, less than 3 quarts in many applications. It would only take a few minutes to drain and check the fluid in all three components and by doing so isolate the problem to one of them. Is the fluid burnt, is it overfull, low on oil, filled with the wrong oil, or is the oil filled with enough metallic debris to resemble mercury? If the noise sounds like it is in the transfer case, but the T-case oil is pristine and correct type, look at the rear end and you might find burnt oil or low oil that is contaminated with metallic debris, and you may have found the cause of the problem. Almost all of the late-model units require very specific oils and very specific amounts, lack of which is the start of a problem.

Recently we had a caller who had purchased a reman Tranzilla six-speed transmission from us and complained of a noise issue. The unit was in a late model Mustang with a 302R Coyote motor. The transmission oil was correct and at the right fill level. The customer called back to say that they had discovered that the engine had less than 2 quarts of oil in it, and that was the source of the noise.

Up-to-date parts

We are running into problems in trying to identify parts that a customer needs due to aftermarket upgrades and modifications in the rear end. Many vehicle owners are adding aftermarket posi carriers to their rear ends such as air lockers or electric lockers. This frequently means that the carrier itself will take a different size set of carrier bearings, than a stock unit. If you are doing rear-end work, you can save yourself and your vendor a lot of time by getting the numbers from the carrier bearings and the pinion bearing to ensure that you receive the correct parts the first time. A common carrier bearing is a LM5013 race, and a LM501349 bearing. A different carrier from stock may use an LM102911 race and a 102949 bearing. Dimensionally, the diameter and thickness of those bearings is the same, but the dimension of the inner bearing bore is very different.

In today’s marketplace many parts are captive to the automakers or discontinued past model product. When they make a contract with Borg Warner, Magna Powertrain and other suppliers to produce a unit, the OEM pays for the tooling and will not permit the supplier to sell parts made on that tooling to anyone else. This is by design to try to send all sales on repair parts back to the dealer. It is shortsighted because if the aftermarket cannot buy OEM, they will have the parts manufactured elsewhere if the volumes are high enough. There are many excellent aftermarket manufacturers who have OEM-quality capability, and there are many offshore manufacturers who will make “will fit” parts of substandard quality. It is up to your gear supplier to do the final quality control to make sure the product is up to OEM specs.

Our company spends a great deal of time making sure any product we sell meets all the OEM dimensions and metallurgy. However, it is also necessary for you to inspect and match any product coming in your door to the original parts in the trans you are working on. Key areas to inspect beside the obvious fitment issues are synchronizer and gears. Make sure that the synchronizer sleeve fits on the engagement teeth of the speed gear with some side play. Make sure all speed gears have some endplay (thrust end play) usually in the range of 20-45 thousandths of an inch.

A common problem occurs in synchronizer rings that need to be matched to the old ring where the key slots are cut for the synchro keys (struts). We have seen low-grade offshore rings where the slots are cut slightly off center, or the slots are cut too tight, and these will never shift under load. During a synchronized shift, the sliding sleeve moves forward pushing the synchro keys into the synchro ring, and moving the ring onto the cone of the speed gear. At this time the synchro ring (blocking ring) prevents the slider from engaging the speed gear until the shaft speeds equalize and then the ring relaxes and turns slightly to let the sliding sleeve engage the speed gear completely, completing the shift. If the slots are machined too tightly or off center, the ring can never function as intended and shifts get blocked out.

Jeep T-case issue

In 2005 and up Jeeps with a 245 transfer case, which is a part time unit, the front and rear diffs usually have electronic locking carriers. To check which rear is a problem you need to lock the transfer case in 4WD high and remove the front drive shaft and test the rear diff. Do the same thing by removing the rear drive shaft and checking the front diff. For states that require dynamic emissions-control testing using a two-wheel dyno, you will damage the center differential in the T-case if you cannot disconnect a drive shaft. I have been trying to locate the program to do that, which uses a scanner in an emissions mode but have not been able to do by press time. I will have that as a sidebar as soon as possible.

Hobbed or milled?

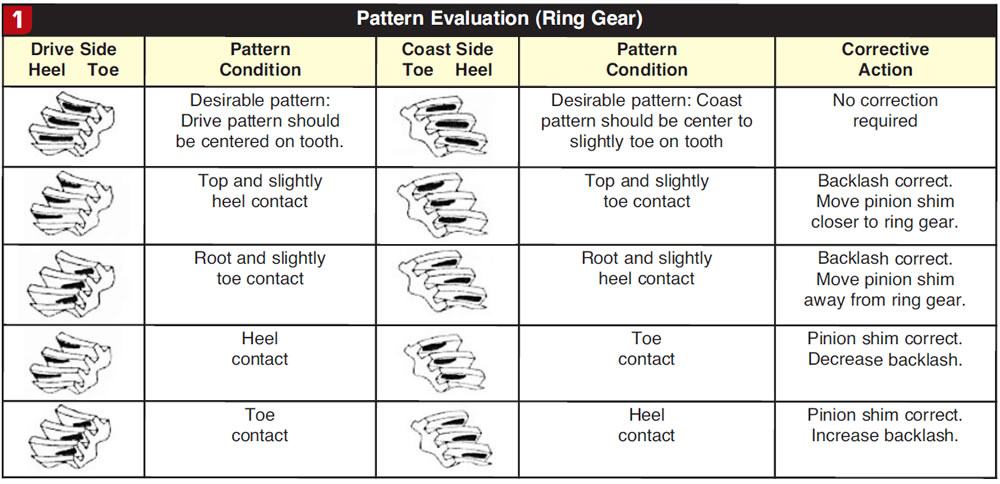

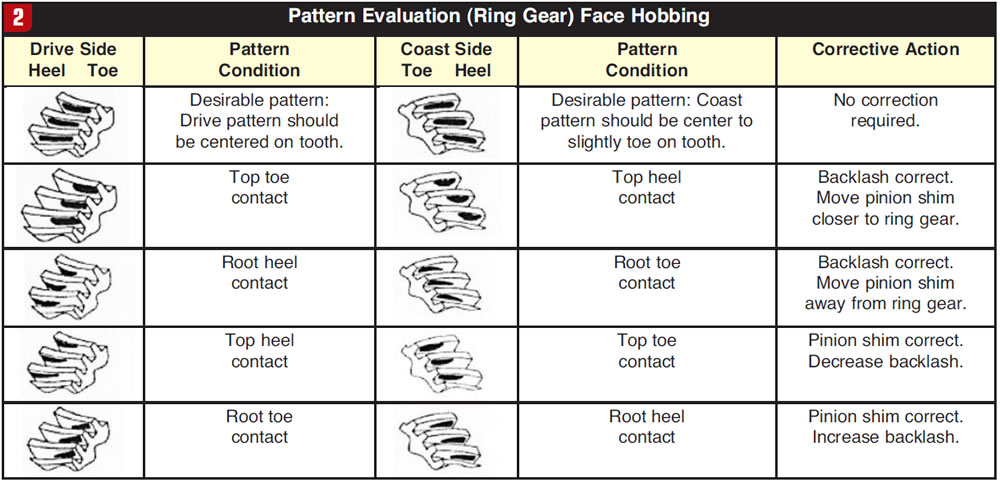

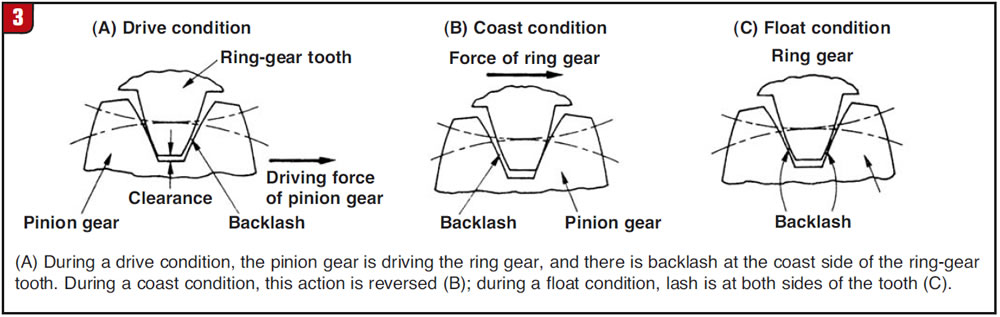

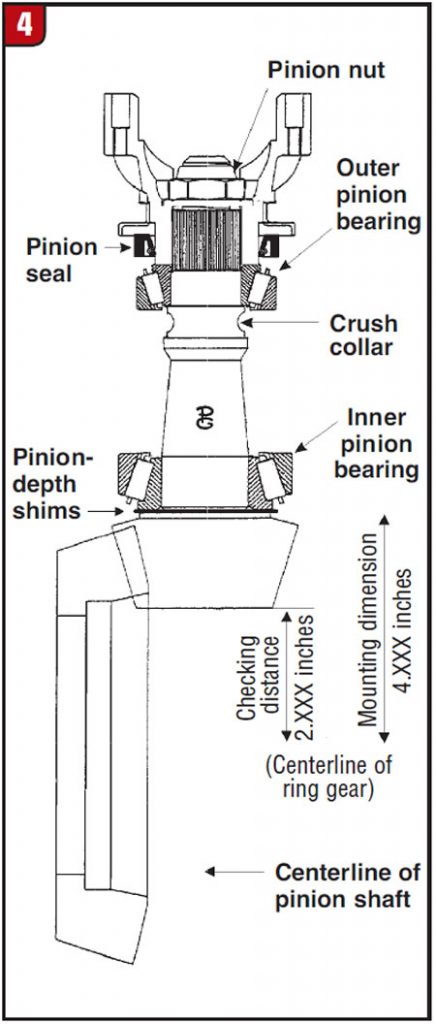

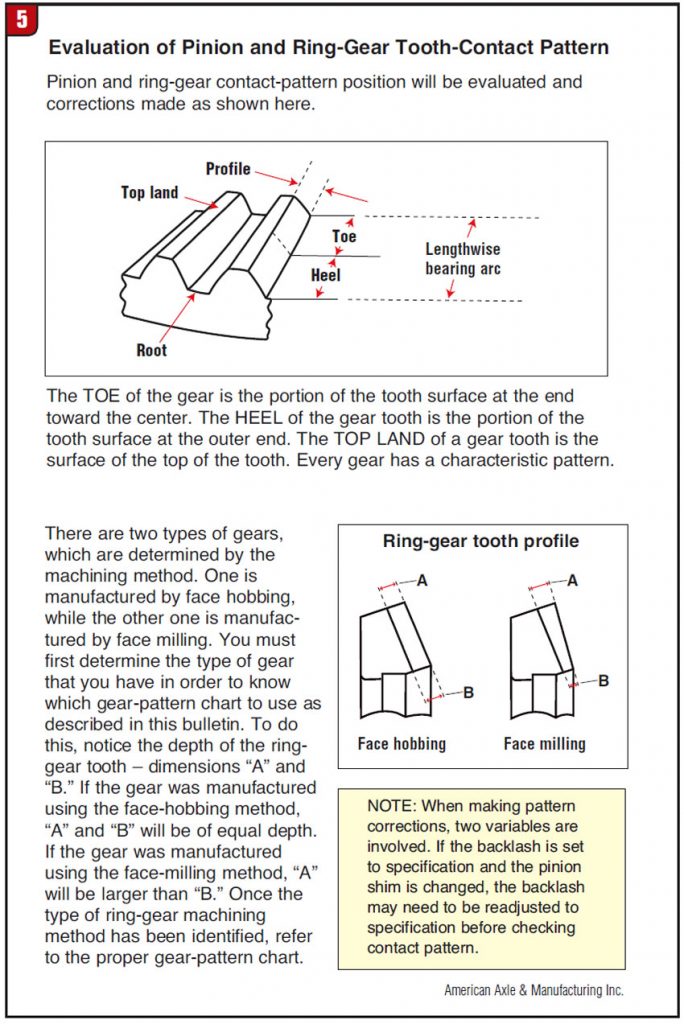

Another common technician call involves ring-and-pinion setup. The product made today is so good that in almost every case you can reuse the original pinion shim with the new pinion. However, there are two types of production methods to make the ring-and-pinion gear and a large difference between the backlash required between a face-cut gear and a face-hobbed gear. Illustrations provided here will help you evaluate what you are working on. Typically a face-hobbed gear will require 4-8 thousandths of backlash, while a face-milled gear needs 8-12 thousandths of backlash. For further reference on this read my article from January 2014 in Transmission Digest.

Mike Weinberg is president of Rockland Standard Gear.