Shift Pointers

- Subject: Poor performance caused by loose ground connection

- Unit: 09G

- Vehicle Application: 2003 Volkswagen New Beetle

- Essential Reading: Rebuilder, Diagnostician

- Authors: Jesse Zacarias and Roy Delfran

“Hindsight is 20/20.”

“Why is there never enough time to do something right but always enough time to do it again?”

These are just a couple of the sayings that come to mind regarding our latest experience with a 2003 Volkswagen New Beetle.

We had repaired the 09G transmission about two months earlier, and the customer came in complaining that it just “didn’t feel right,” especially when she was at a stop sign for a long time; “it did not feel like it had the same power.”

When we asked her whether there were any lights illuminating on the dash that might indicate a problem, she replied that she had not seen any.

We started by checking the obvious and road-tested the vehicle. Since we didn’t detect any problems we asked her to leave the car so that we could check it further. When we checked the battery we noticed that it had 12.2 volts (only 50% charged). When we mentioned this to the customer she told us that her battery was about 6 years old. Based on the age of the battery and the fact that the voltage at the battery post with the engine running was about 13.8 (first assumption), we recommended a new battery.

When we installed the new battery we checked the charging system again (the lazy way mentioned previously), and since we saw 13.8 volts we released the vehicle. A few days later she came back complaining of the same problem. This time when we checked the charging system (same old lazy way) we noticed that the generator was not charging, so we recommended replacing the generator, because this type of generator uses a one-way clutch on the pulley and is known to go bad, so we figured (assumed) that that was why we had seen the system charge at some times and not others.

So we ordered and installed the generator, and when we checked it (the old lazy way) we had 13.8 volts, but this time we left the engine running for a while. We connected our scan tool so that we could road-test the vehicle and get some readings we were after. It was here we noticed that the battery-voltage parameter was reading 11.2.

It has been our experience that most of the mistakes we make in electrical troubleshooting are caused by cutting corners because we are too occupied on other matters. Well, now it was time to check the charging system the correct way.

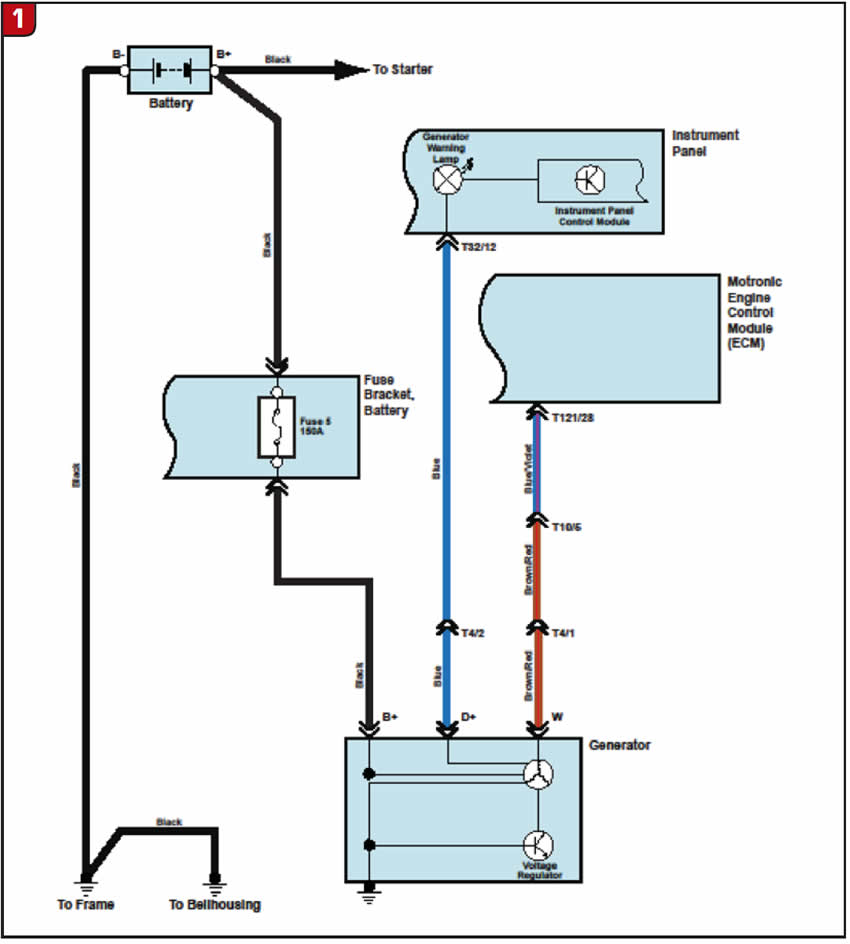

We installed our scope with Channel 1 (yellow) back-probing pin W at the generator (Figure 1). This is where the ECM controls the voltage regulator and would allow us to see the voltage regulator’s performance and at the same time see the integrity of the circuit between connection W at the generator and pin #28 of the ECM. Channel 2 (green) was connected to the battery positive post. This is the best place to check for charging voltage (instead of at the back of generator B+), because you want to make sure the charge is getting to the battery and not just coming out of the generator.

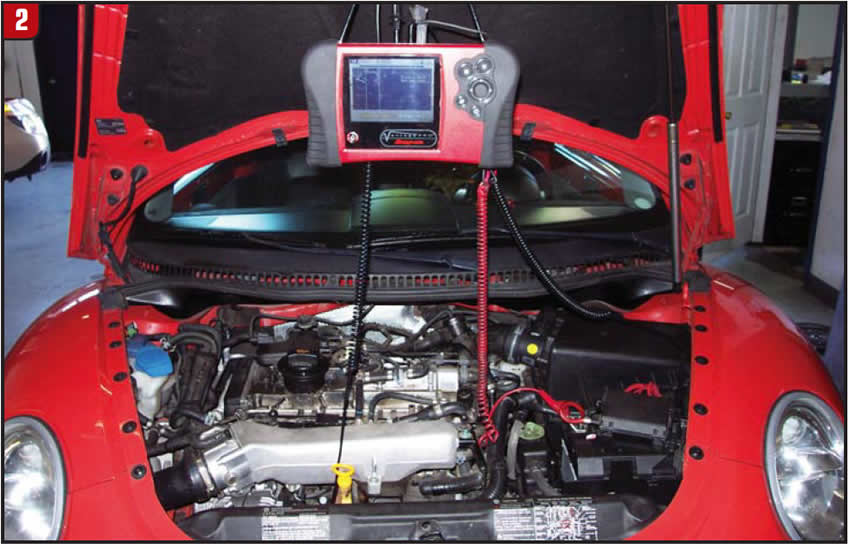

Finally, the scope was grounded at the battery ground so that all references were to battery ground, which would allow us to see the integrity of the ground (Figure 2).

With the ignition on, the generator warning light would come on (exciting the generator), and when the engine started the light would go off, indicating the charging system to be normal. In this particular design if the generator warning-light bulb at the dash were not working, there would be a good chance the generator would not be excited and therefore not charge.

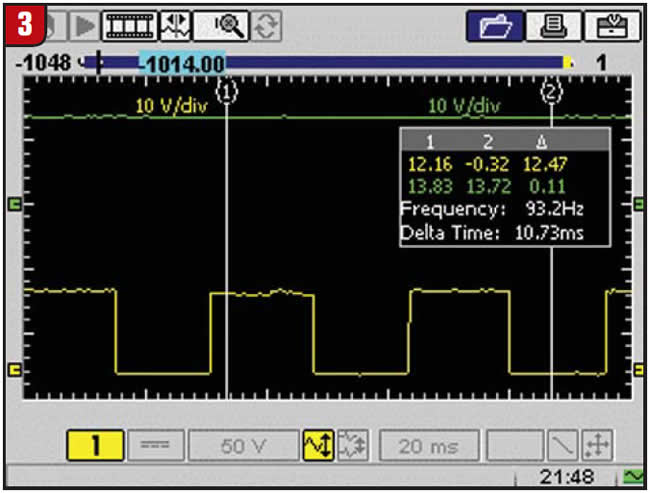

The scope showed a 320-mV drop on the ground side, but the charging voltage at the battery was 13.7 (Figure 3, cursor 2). An acceptable voltage drop between generator ground and battery ground should not exceed 200 mV; therefore, we immediately suspected a ground problem, but we decided to let the engine idle for a while.

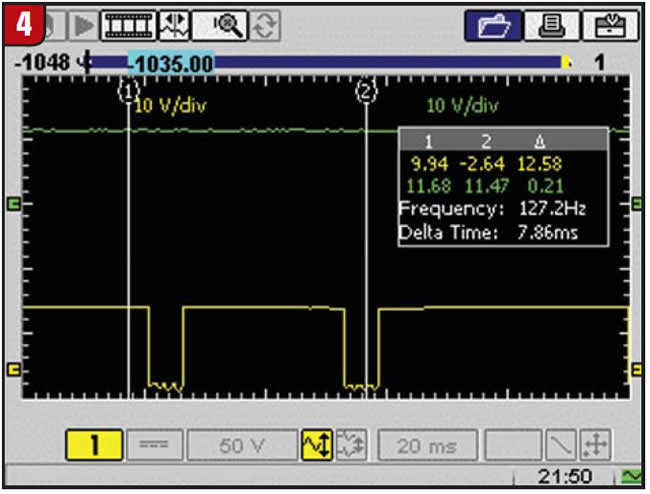

After a while we noticed the voltage at the battery to be 11.47 and the voltage drop at the negative side of the wave (field off) to be at 2.64 (Figure 4, cursor 2); definitely a ground problem. We also could see the ECM leaving the field on for a longer time, trying to excite the generator.

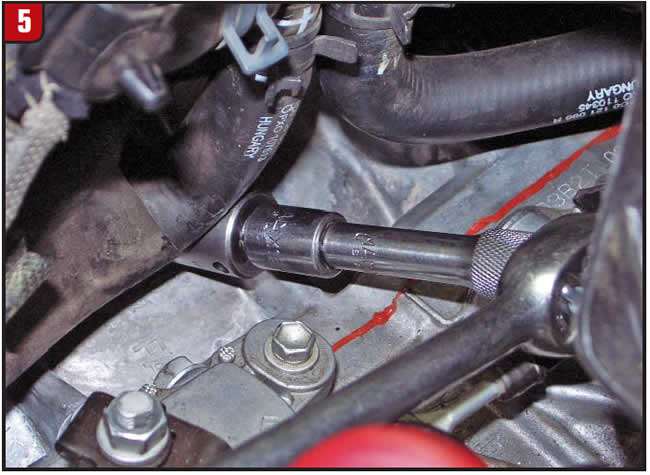

After looking for the ground for the generator body (engine ground), we found it was at the transmission bellhousing bolt (figures 5 ). This is a bolt with a stud at the tip where the ground connects and is held on by a nut (at a very difficult place). We had left the nut loose just enough to work at times. This is the same ground that illuminates the generator warning light at the instrument panel, which is why we think it never came on when the generator voltage was low at the battery.

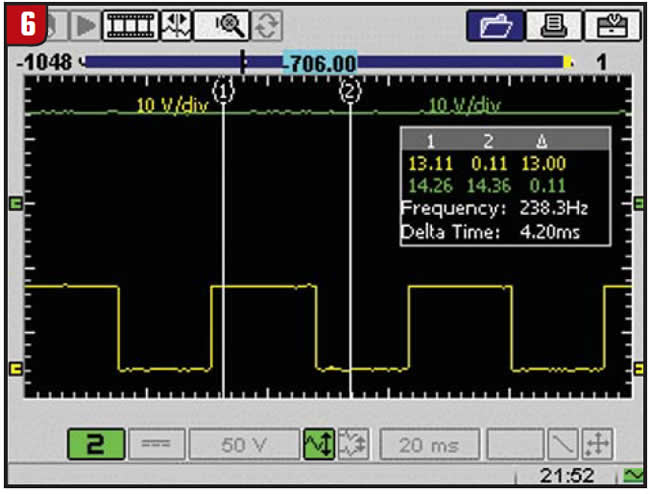

After we tightened the ground, the system returned to good working order and the ground never dropped below 110 mV under load (Figure 6, cursor 2).

This would explain the poor performance. With the faulty ground using up 2.64 volts, this left only about 11.5 volts available for the vehicle’s electrical system. This was not enough voltage to make the injectors perform well, not to mention the poor performance of the fuel pump.

When we mentioned to our customer that all the problems were caused by a “loose nut” (no pun intended), she was kind enough to pay for the parts at cost, even though we were not willing to charge her anything.

Now, all this could have been avoided had we taken the time to do the proper voltage-drop tests under a load, but then again, who has time, right?

Jesse Zacarias is the owner of Elec-Tran Diagnostics in Gilroy, Calif. Roy Delfran is with Snap-on Diagnostics’ Ask A Tech Community Web Forums (http://askatech.snapon.com).