R&R Tech

- Subject: Harsh 1-2 shift

- Unit: AX4N (4F50N)

- Vehicle Application: 2004 Ford Freestar

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Jody Carnahan

I received a call from one of our wholesale customers, a shop that does general-repair and transmission work on occasion. He was looking for help on a 2004 Ford Freestar that he could not get to leave his shop. In fact, the vehicle had been to several other shops. He told me that another shop had worked on the transmission recently and that it was now back in his shop.

I asked him what the previous failure was, and he said it was a problem with a second-gear slip. They had removed the transmission and found that the intermediate-clutch-piston bonded seal was damaged, and that was all that was done to repair the unit. Now that they had it all back together, the transmission banged hard on the 1-2 shift. It was not setting any codes, and from what the shop could tell everything with the vehicle and the load sensors were working properly. I decided to take on this challenge and had him drop the vehicle off at our shop.

My diagnostic process started with our normal procedures: hooking up a scan tool and putting a pressure gauge on the EPC pressure tap. EPC-pressure command on the scan tool and pressure on the pressure gauge appeared to be normal. I put the scan tool into the graphing mode so that I could capture and record the pressure-control readings during the upshifts and compare them with a graph that I had on a normally working 4F50N.

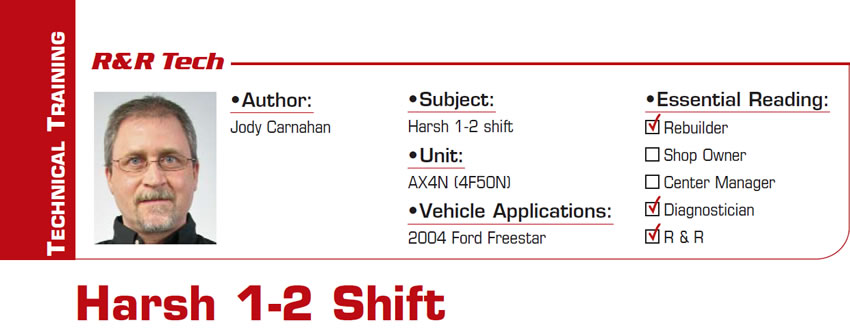

We found that on a normally working transmission, the computer would ramp up the EPC pressure just before the 1-2 shifts and that during the shift it would come back down (Figure 1).

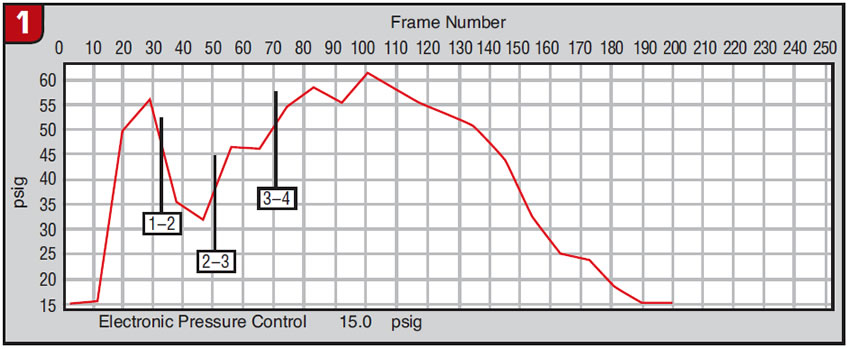

We then graphed the EPC pressure on our vehicle with the harsh 1-2 shift, and it appeared that the PCM was trying to compensate for the aggressive shift. Because the computer never ramped up EPC pressure before the 1-2 shift it stayed steady before and during the shift (Figure 2). On the basis of this information, we concluded that the PCM was working properly and that it was not the cause of the problem. We also ruled out the EPC solenoid, because with a pressure gauge hooked to the EPC pressure port we were able to confirm that it was following EPC command.

On the basis of the scan-tool and pressure-gauge data, we needed to start looking for the problem inside the transmission. We needed to identify which component(s) we were going to look at first and also needed to decide whether to try fixing this one in the vehicle or to remove it and put it on the bench. We decided to try a fix in the vehicle and went after the valve body, hoping we didn’t have a problem with the channel plate or with an accumulator piston.

Before removing the side cover and pulling the valve body, I wanted to verify which valve-body component could be causing our issue, such as a particular valve, possible checkball in the wrong location etc. In doing research on the 4F50N, I knew there were several differences in valve bodies among model years. Taking a look at the factory manual, I saw that the 2000-2003 valve body did not have a 1-2 capacity-modulator valve and used a checkball (B10) to orifice intermediate clutch oil to control shift feel. If the B10 checkball was missing, non-orificed oil flow into the intermediate clutch would cause a harsh 1-2 shift.

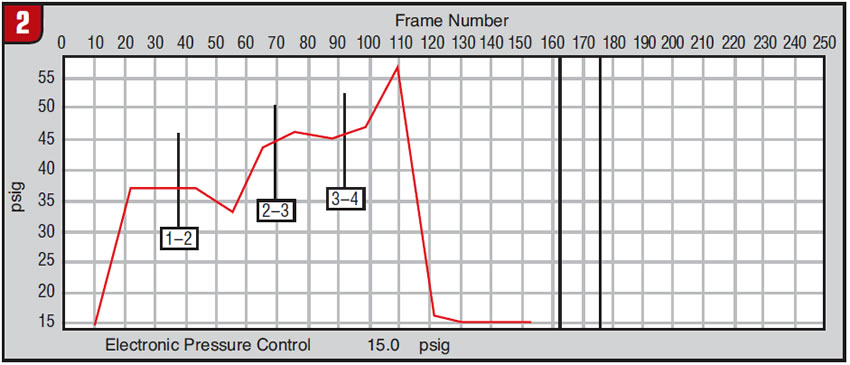

As I said earlier, we were working on a 2004 Ford Freestar, and there were some changes in the valve body in this model year. The 2004-up 4F50N went back to using a 1-2 capacity-modulator valve just like the earlier AXODE/AX4S models. Having this information in hand gave us a good direction to start looking, and we removed the valve body for inspection.

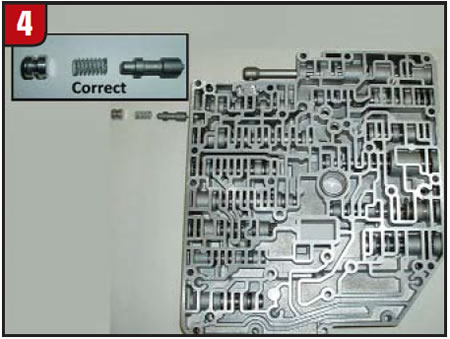

We first inspected the 1-2 capacity-valve lineup, and everything appeared to look normal. The valve stroked fine in the bore and the spring appeared to be in the correct position against the bore plug. We found the problem when we removed the valve: It had been installed backward (Figure 3).

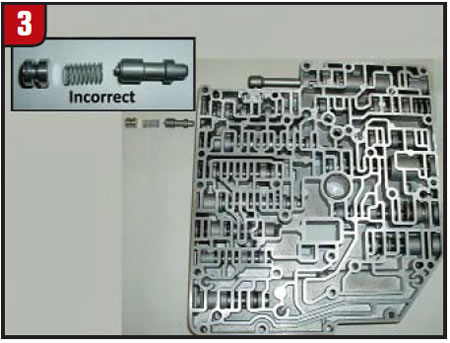

With the valve in backward, the land of the valve blocks off the accumulator, causing a harsh 1-2 shift. We turned the valve around and installed it correctly (Figure 4), put the valve body back on the unit and road-tested the vehicle. The transmission shifted correctly. We also hooked up the scan tool so we could graph the EPC command and see whether it changed back to having the normal spike before the 1-2 shifts. It looked almost identical to the graph we had of one with a good 1-2 shift.

In conclusion, please refer back to the graphs in figures 1 and 2. When we ran the graph on a known-good 4F50N, it was similar to the graph in Figure 1. The graph in Figure 2, illustrating a harsh 1-2 shift, is the only graph that we have seen with a harsh-shift complaint.

Although this one test may be as inconclusive as the weather, we can in fact use this test as a way to determine a harsh-shift condition. We will be graphing more vehicles with felt harsh shifts in the future in hopes that this data can be useful within our industry.

I would like to challenge all the readers of this article to provide feedback to me regarding whether the PCM in this case can detect the harsh shift and adjust the duty cycle to compensate for this condition.

Jody Carnahan has been with Certified Transmission almost 25 years. He is a warranty and technical director and also has been a builder and a department and store manager.