Technically Speaking

- Subject: Shift-bump complaint

- Unit: 4R75W

- Vehicle Application: Ford F-150 4×2

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

In an ATSG seminar several years back we covered a noise problem with Ford’s 5R55W/S transmissions in 4×4 applications. The description of the noise was either a clank or metallic-type noise during any forward or reverse engagements. The noise was typically perceived as a differential or transfer-case problem.

What usually caused this complaint was condensation in the area between the output-shaft splines and the transfer-case input splines causing the splines on the output shaft to rust (Figure 1). The deterioration of the spline caused by the rust compromises the shaft movement, producing the clanking or metallic-type noise. If the output shaft was not badly damaged, a good cleaning and some synthetic grease could remedy the problem. In some instances replacement of the output shaft would be required along with the added synthetic grease.

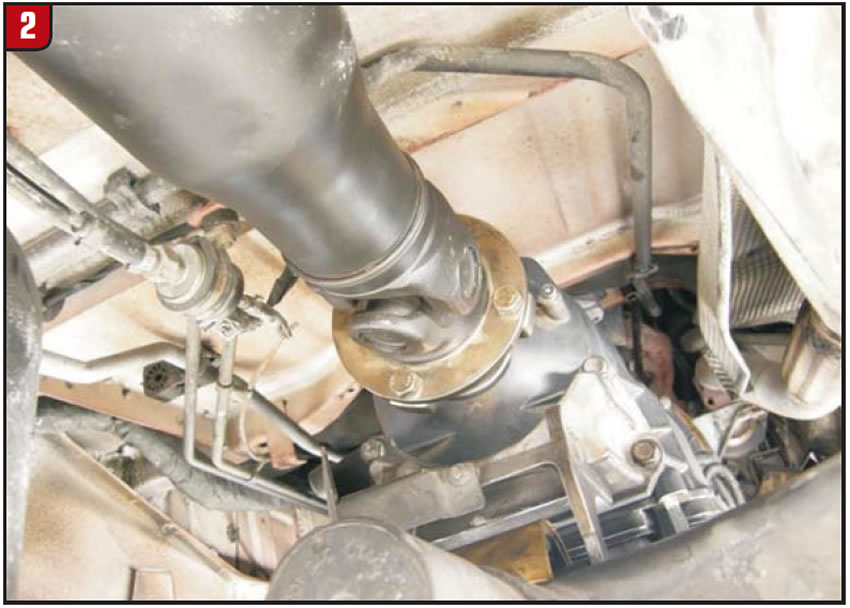

This year we covered yet another similar complaint caused by a spline-related issue with certain Dodge, Chrysler and Jeep vehicles equipped with the NAG1 transmission. In these instances the output flange that bolts onto the output shaft needed to be replaced to correct this noise condition (figures 2 and 3).

Recently here in Miami, we had a shift-bump complaint in a 2005 Ford F-150 4×2 with a 4R75W. The owner uses the truck, which had 48,000 miles on it, to pull a 27-foot boat. He started noticing a bump on both a coast downshift and a no-load 1-2 upshift. He had been to the dealer, since he has an extended warranty, but to his dismay his drivetrain was conveniently not covered. So, of course, the dealer tried to sell him a new transmission.

When ATSG technician Jose Garcia received the phone call on it he went to check it out himself. When he drove the vehicle it absolutely felt like a hard 1-2 shift and a 2-1 downshift bump. It did not feel like a driveline problem in any way. The fluid level was good, and the fluid looked and smelled good as well. There were no codes, and line pressure was textbook perfect. So before any work was performed, we checked to see whether there were any Ford technical-service bulletins related to the complaint. Jose found one that spoke about a driveline clunk or bump complaint. TSB 05-26-11 recommended using 7 to 13 grams of Motorcraft PTFE lubricant on the slip yoke.

This truck has a four-door cab so it uses the dual driveshaft, and we thought this could be the problem. However, when the driveshaft was removed we all had our doubts that this would fix the problem. Visually there were no signs of anything wrong. It was still very much lubricated, and it slid in and out with no issues (Figure 4). But we greased it, reinstalled it and, voilà! The problem was solved. So the customer got greased in a completely different way from what the dealership had in mind. It’s interesting that since this experience, the shop has had yet another similar vehicle come in with the same problem getting greased for another job.