Shift Pointers

- Subject: Solenoid codes after installation

- Unit: VW 01M

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Frank C. Kuperman, President, Phoenix Remanufactured Transmissions

For those select few of you who have taken on the task of either rebuilding or installing a Volkswagen 01M transmission, you know that these units can be difficult. This transmission is very easy to rebuild, and usually the internal parts are in good shape.

Sounds great, doesn’t it? Well, not necessarily; your problems may very well be outside of the transmission. What once seemed like an easy job may turn into one of the most-frustrating and expensive jobs you have ever taken on.

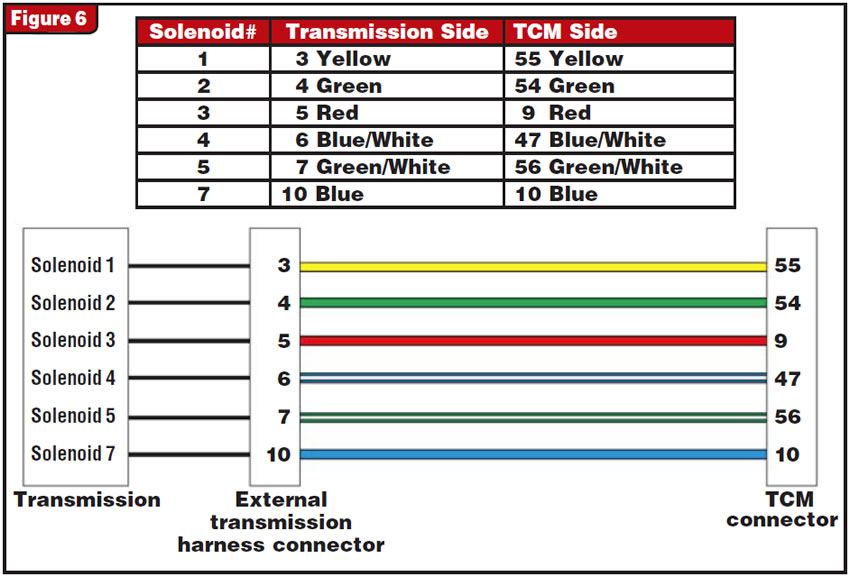

One of the most-common problems and baffling technical mysteries that arise after installation of one of these transmissions is solenoid codes that are impossible to clear and locate. These codes are described as solenoid short to ground and will occur for solenoids 1-5 and 7. Solenoid 6 will not be affected, as it does not share a common connection with the others.

Your first instinct, as a good rebuilder or shop owner, is that you have a bad solenoid ribbon connector. In fact, VW’s own troubleshooting guide notes that you may have either a bad solenoid or a faulty valve-body ribbon connector. After replacing the solenoid you try to test-drive the vehicle again, but to no avail.

Your next step is to replace the computer ribbon cable inside the transmission on the valve body. This is a costly replacement. Again, you try to initiate a test drive, but you still have the same solenoid codes. Since you now have replaced everything except for the control module, it seems that the only possible faulty component would be the module.

After replacing the solenoid, ribbon cable and, now, the transmission control module, you make another attempt to clear the codes and test-drive the vehicle. After you’ve spent more than $1,000, the persistent and baffling solenoid codes are still present. After exhausting all your own internal resources and knowledge, you reluctantly have the vehicle towed to your local VW dealership.

The next day, you receive a phone call from the service adviser, who tells you that you need to replace the TCM. You inform him that you have already replaced the module and the same or different solenoid codes still appeared. After the adviser comprehends this, his next suggestion is to replace the transmission, even though you have replaced the solenoid(s) in question and the ribbon cable and have rebuilt the transmission completely. Reluctantly, you take the vehicle back and either remove the transmission and go back through it again or order one from your local reman supplier.

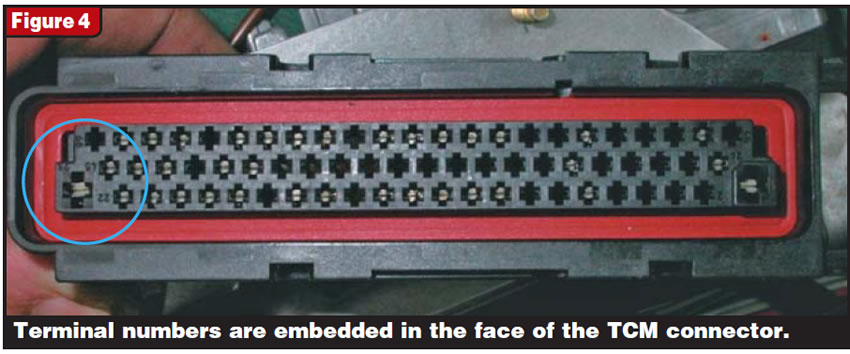

Upon installation of the new transmission you find that the solenoid(s) codes are still present and cannot be cleared. After a thorough visual check and resistance check, it seems that all the wiring and electrical systems are working properly. At this point it seems as if the vehicle will never leave. So what is the problem?

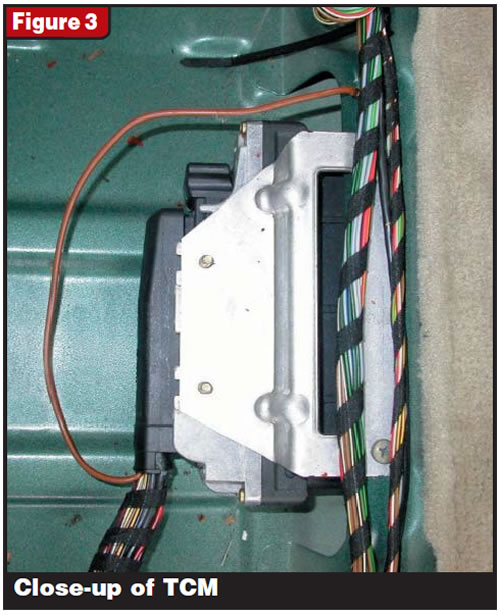

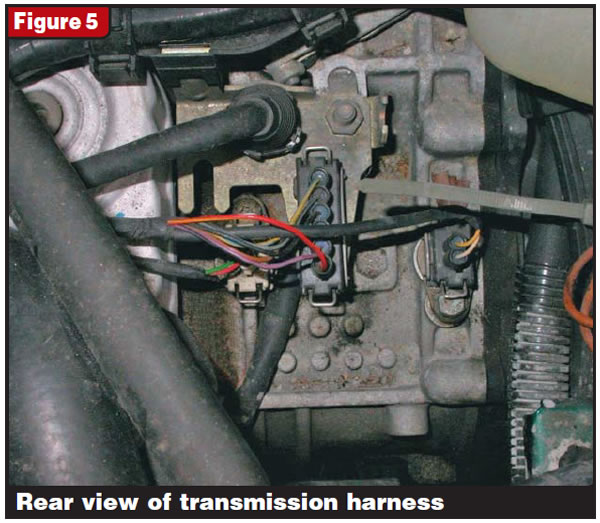

The problem lies in the vehicle wiring harness between the TCM and the transmission. This harness snakes its way all over the place before it actually winds up at the TCM. Somewhere along its path, it has worn through the insulation and has developed an intermittent short to ground that doesn’t seem to appear unless the vehicle is running, and you may never catch it in the act. You may even deliver the vehicle to the customer thinking it is operating correctly, and the customer may drive it for a few days before the issue arises.

This baffling and expensive issue can be quickly and easily fixed for just a couple of dollars and an hour or so of time – that is, after you complete the simple repairs described in this article.