Up To Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: A budget-busting unit to fix

Manual transmissions are in a continuing decline in volume. Most current manual transmissions in domestic vehicles are relegated to the sports or “muscle-car” segments of the market. Of the “Big Three” domestic manufacturers, only Ram options a manual transmission for purchase; Ford and GM do not. Part of this decline is a lack of ability in the driver population, who are used to automatic transmissions so that nothing interrupts their ability to text while driving. Additionally, the EPA does not like stick transmissions because they cannot control the throttle opening during operation.

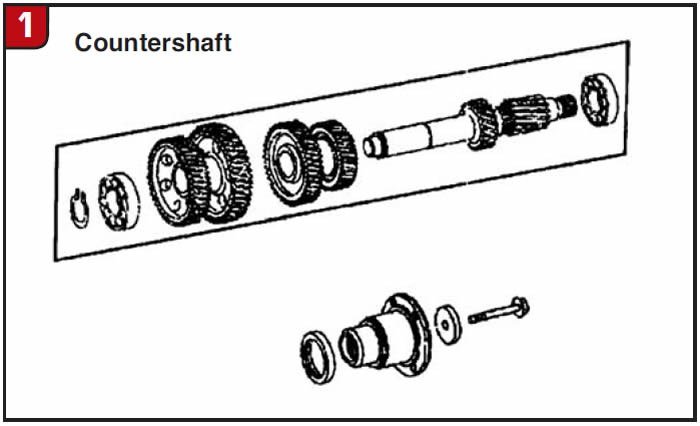

Automatics shift under open throttle, which makes it much easier to manage fuel and emission controls, whereas the driver has full control over the throttle and shift points with a manual trans, which will be shifted under closed-throttle conditions. A further consideration is strength and torque limitations. A manual transmission with a single countershaft will have 3 or possibly 4 teeth in mesh between the speed gear and the counter gears. Automatics with planetary systems will have 3 or 4 times the amount of tooth contact in the gear train.

The G56 is a design evolution of the New Venture 5600. Dodge used the 5600 from 1998 through 2005 in 2500 and 3500 series trucks. An extremely heavy cast-iron case unit, the 5600 suffered a perennial problem of failed pilot bearings where the main shaft entered the input shaft. The most difficult area to ensure good lubrication is inside the input gear, as most manual transmissions are splash lubricated.

The Ford M5R1 and 2 units, which were designed by Mazda, used a plastic shield on the input shaft to push fluid into the input-shaft pocket. Other manufacturers like Tremec have designed internally pressurized lube systems with an oil pump in the front plate driven by the countershaft.

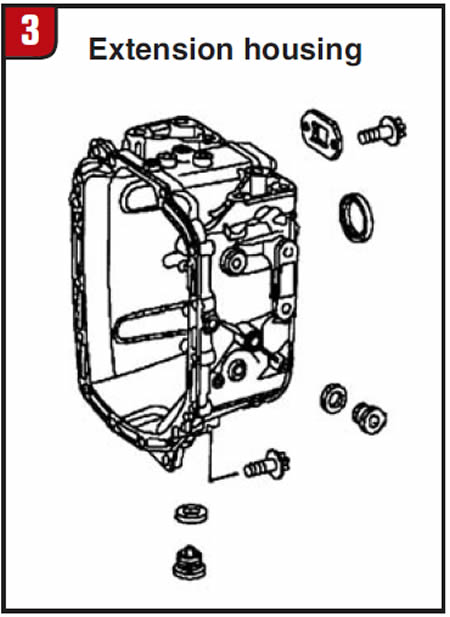

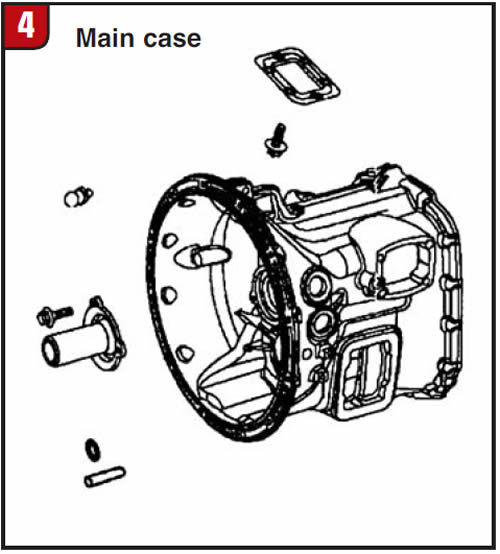

The 5600 was replaced during the 2005 production cycle by the G56. This came about due to the merger of Daimler-Benz and Chrysler and the need for a lighter, more efficient heavy-duty transmission. The G56 is an aluminum-cased unit with the bell housing integral to the main case, and a separate rear case extension/housing.

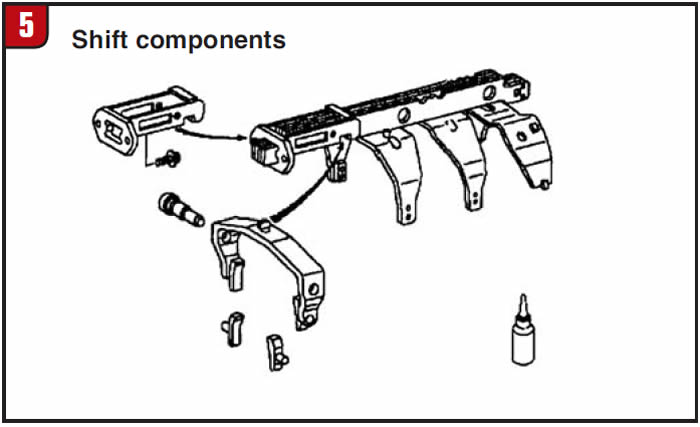

Mercedes redesigned the internal gear train and shift mechanism, similar to the NSG370 used in Jeeps. Stamped steel shift rails and multiple cone synchro rings are just larger in the G56. From 2006 on there were no more NV5600 units produced. The G56 is found behind the 6.7 Cummins diesel engines in 2500, 3500, 4500, 5500, and Mercedes Class 4 and 5 trucks. The units are equipped with provisions for power takeoff units, and in 2WD and 4WD models.

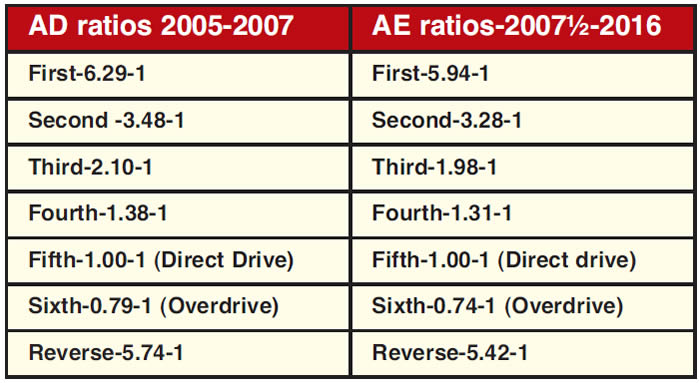

The G56 has 2 ratios, AD and AE. The letters are the last 2 digits on the transmission bar code.

AD ratios 2005-2007

- First-6.29-1

- Second -3.48-1

- Third-2.10-1

- Fourth-1.38-1

- Fifth-1.00-1 (Direct Drive)

- Sixth-0.79-1 (Overdrive)

- Reverse-5.74-1

AE ratios-2007 ½ -2016

- First-5.94-1

- Second-3.28-1

- Third-1.98-1

- Fourth-1.31-1

- Fifth-1.00-1 (Direct drive)

- Sixth-0.74-1 (Overdrive)

- Reverse-5.42-1

NOTE: A great bulk of the transmissions you are used to have 4th gear as direct drive 1-1 ratio with no power flowing through the cluster gear. Many European designs use 5th gear as the direct drive 1-1 ratio, which makes a huge difference in diagnostics and noise complaints.

The G56 is torque rated at 610 lb.-ft. for the AD ratio and 660 lb.-ft. for the AE ratios. The unit weighs 225 lbs. and uses 4 quarts of lubricant. Dodge gives ATF +4 as the required lubricant, while Mercedes specs 75W/90W lubricant. There has been much written about noise in operation about this unit. While all transmissions have some inherent noise, the G56 running on ATF+4 is not a pleasurable ride. The 75/90 weight is quieter but presents some cold-shift problems in northern climates. MobilTrans SHC DC seems to run quieter than anything else.

This is a strong workhorse unit behind a stock Cummins 6.7. The problems arise with owners boosting up the 6.7 with all manner of power adders. It is not impossible to reach 1400 lb.-ft. of torque out of this motor by playing with the computer and turbos, etc. This unit will suffer cracked and broken cases at that level of abuse. There are many owners adding dual-disc clutches that will create a bunch of gear-rollover noise due to harmonics from the engine now rattling the gears. It is very important to get all the facts from your customer before diving in to the deep end of the pool. Make sure to ask if the unit is stock as it came from the factory or has it been modified beyond the design limits of the components. These trucks will have an Aisin AS69RC 6-speed automatic that can handle more torque that the G56.

The G56 uses a gear design that has a removable gear cone on the input shaft similar to an NV4500, and uses multiple cone synchronizer rings. Be very careful in quoting repair costs as these rings are incredibly expensive, and must be purchased as a set. The 1-2 synchro assembly complete lists for $1,785, The 3-4 synchro assembly complete lists for $2,045, and the 5-6 synchro assembly lists for $1280. We will have a source for these parts soon that will be quite a bit cheaper, but this is one budget-busting unit to fix.

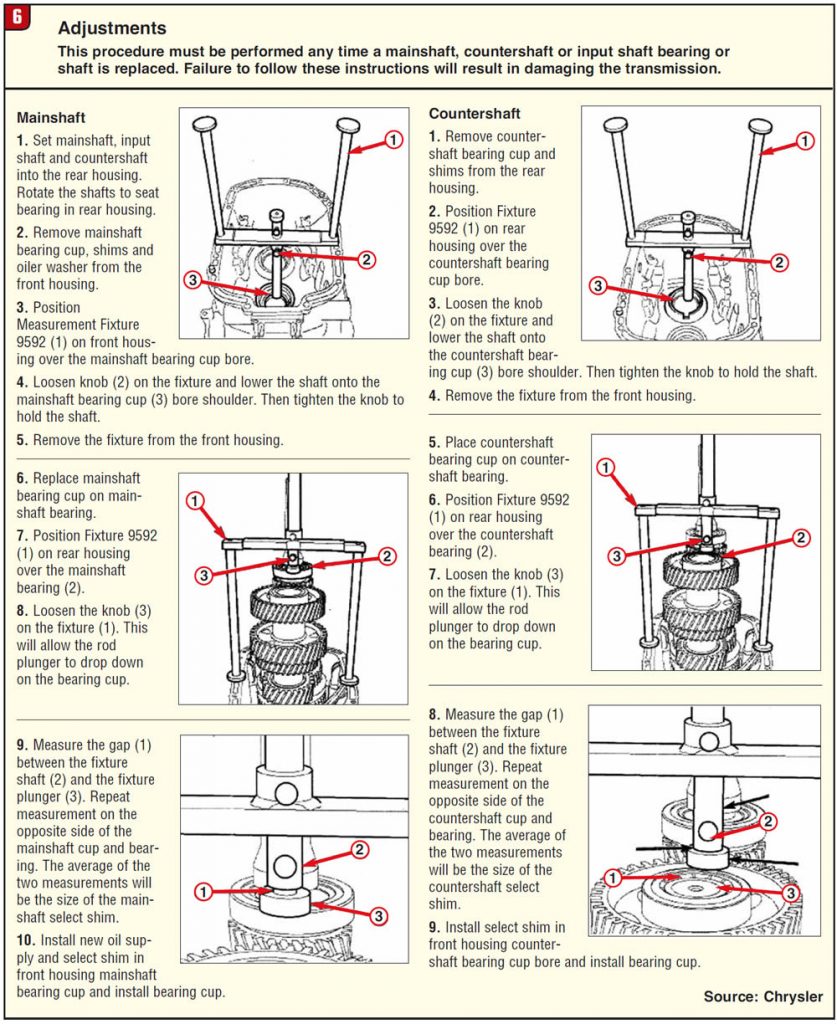

These units use tapered roller bearings to locate and support the shafts. As usual endplay and rotational torque specs are critical to a long lasting quiet repair. Dodge specifies a special tool (part #9592), which they call a measurement fixture to establish the endplay shim requirements. I assume this will be an expensive investment, unless you are doing more than one unit. You could make your own gage, or in a pinch you can use roll solder. Cutting a piece of roll solder and fashioning it into two half-moon pieces starts you off. Place the half-moon segments under the bearing cup, between the bearing and the case on both front and rear cases.

Install the shafts (input, output, and counter), assemble the cases and bolt them together. Disassemble and measure the crushed solder, which will act like plastic gauge on an engine crank, to give you the maximum shim size. In the end you want to achieve a zero endplay with a zero preload on the shafts. This will usually create an average of 2-3 thousands endplay as the cases expand due to operating temperatures. Do not put any preload on the bearings as they will spin the cones in the cases.

Mike Weinberg is president of Rockland Standard Gear.