Torque Converter Tech Tips

- Subject: Front-seal blowout after replacement of torque converter and related parts

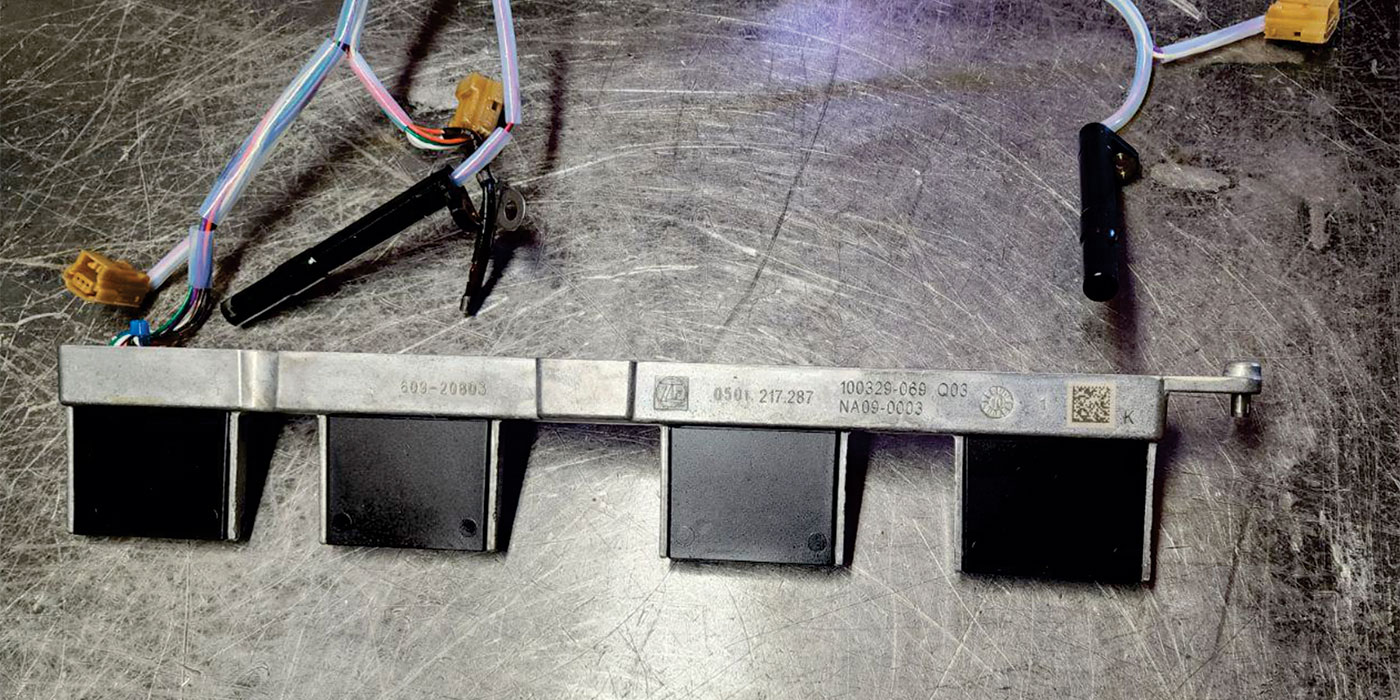

- Unit: AW TR-60SN/VW 09D/T

- Vehicle Applications: 2002-10 VW Touareg, 2003-10 Porsche Cayenne

- Essential Reading: Rebuilder, Diagnostician

- Author: Marc van Aalderen

The Aisin AW TR-60SN/VW 09D/T transmissions are found in the 2002-2010 VW Touareg and the 2003-2010 Porsche Cayenne. There have been reports of the front seal blowing out after the torque converter and related parts have been replaced.

The root cause of the seal blowing out is the buildup of pressure because the drain-back passage that normally vents the area behind the front seal is blocked. This area is normally vented through the stator support/pump cover. The seal-blowout issue occurs when the pump (body and gears) is mated to an incorrect stator support (pump cover) and blocks the drain-back passage. To understand how easy it is to make this mismatch, you need to know the large number of possible combinations. Be aware that the seal-blowout problem is only one of several issues that you can create if you mismatch components.

The first thing you will find is that the vehicles with the smaller engines have a torque converter with a single lockup clutch, and the vehicles with the larger engines have a clutch-pack-type lockup clutch similar to that of the Mercedes 722.6. The torque-converter-clutch (TCC) circuit for the single-clutch converter uses the conventional two-path lockup hydraulics in which the converter charge/TCC release oil enters the converter through the input shaft. The clutch-pack style of this converter uses a three-path hydraulic lockup in which the TCC apply oil enters the converter through the input shaft.

Because of the differences in the two- and three-path hydraulic circuits, many of the related parts are different. The input shaft for the two-path lockup circuit is smaller in diameter and has three sealing rings; the larger-diameter input shaft used with the three-path circuit has four sealing rings. These shafts are not interchangeable. The valve bodies for the two- and three-path units also are different.

Mismatching the valve bodies will either result in no lockup or cause the engine to stall as soon as the vehicle is placed into gear.

If this was not confusing enough, there is an early bushing-style pump and a late-model needle-bearing-style pump for both two- and three-path units. To make matters even worse, the bushing- and bearing-style pumps use a different outside diameter on their respective converter impeller hubs. The bushing-style hub (Figure 1) is the same 45.15mm (1.778 inches) for its entire length, while the bearing-style hub (Figure 2) is 44.95mm (1.770 inches) and steps down to 44.30mm (1.744 inches) where the pump gears ride.

The early bushing-style converters can be upgraded to the late-model bearing style by simply replacing the impeller hubs.

Since the early bushing-style pumps have a high failure rate, they are not as desirable or readily available. Upgrading to the bearing-style pump is a common practice, but this is where the mismatch occurs that causes the seal to blow out.

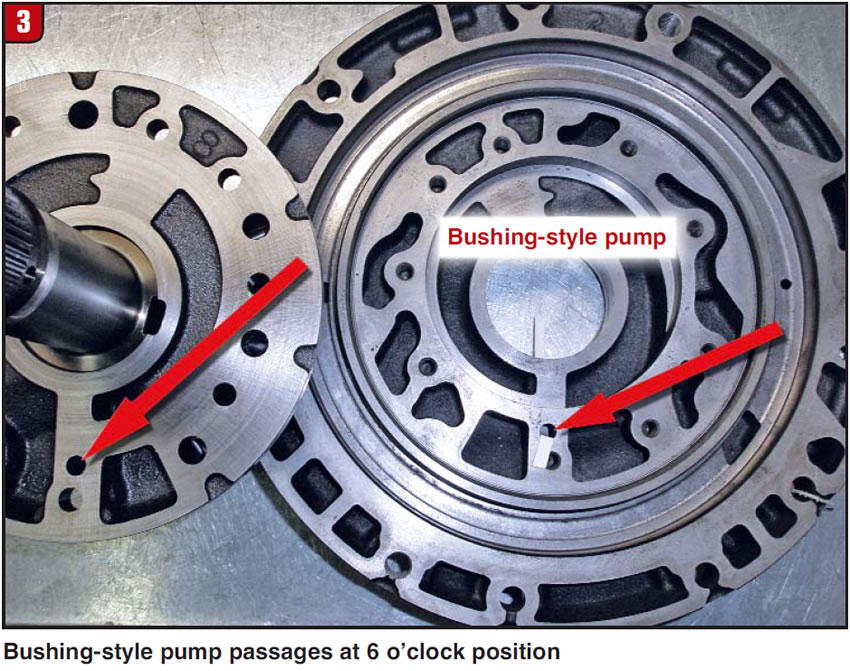

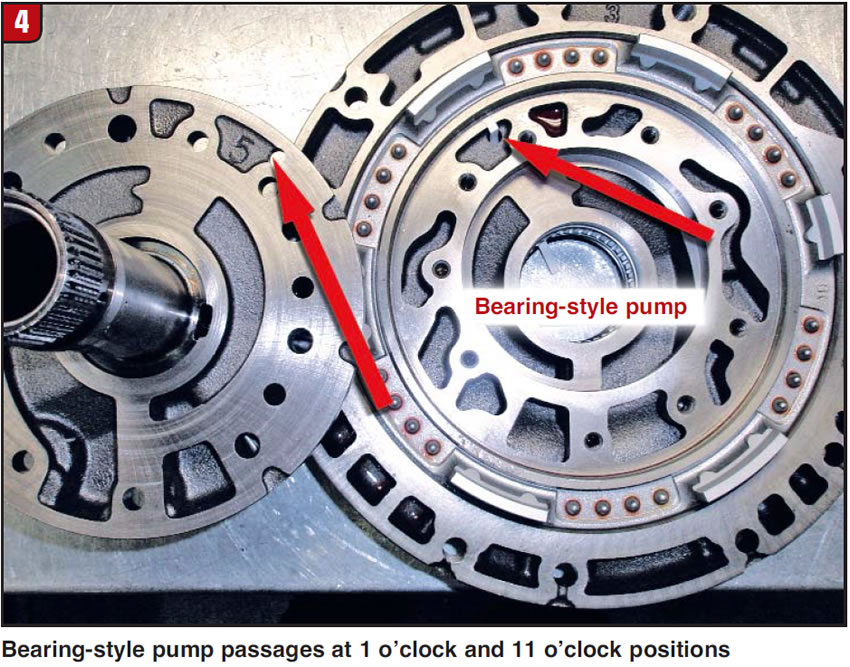

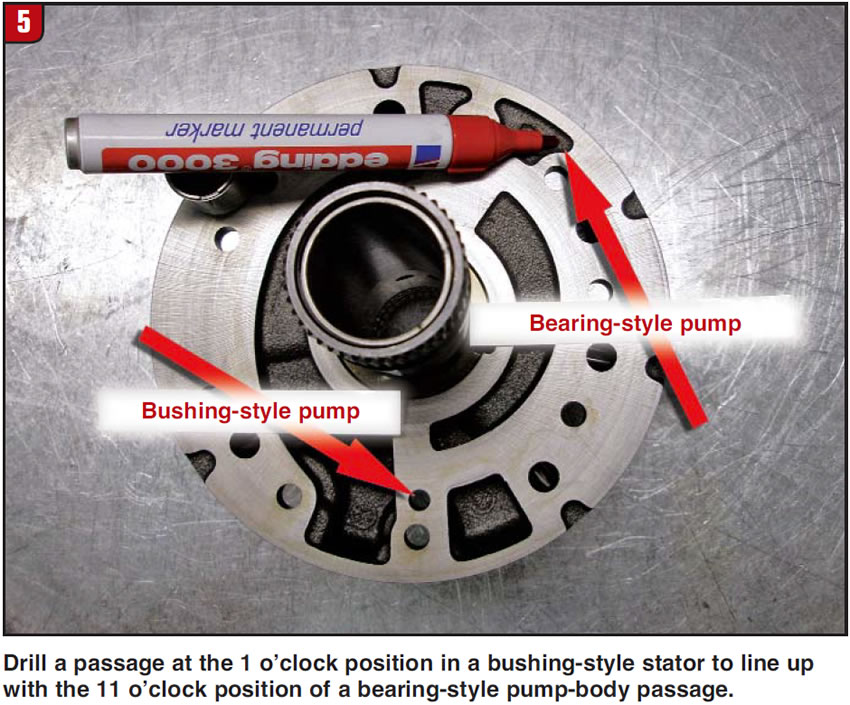

The early bushing-style pumps (Figure 3) have the drain-back passage at the 6 o’clock position, and late-model bearing-style pumps (Figure 4) have drain-back passages at the 1 o’clock and 11 o’clock positions.

When you are mating a late-model pump to an early-model stator support/pump cover, you must drill the stator support so that the drain-back passage continues through and lines up with the pump-body passage (Figure 5).

If you are not replacing the pump assembly as a unit, always be alert to the possibility of a blocked drain-back passage.

Marc van Aalderen is production manager at Valve Body Xpress, Europe. Valve Body Express is a member of the Sonnax TASC Force™ (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.

©Sonnax2011