Torque Converter Tech Tips

- Subject: Correcting and preventing stator problems

- Essential Reading: Rebuilder, Diagnostician

- Author: Ed Lee

In the early days of torque-converter rebuilding, most of the routine work involved re-machining thrust surfaces and then restoring clearances. Available service items such as thicker thrust washers and thicker end caps made this work relatively easy.

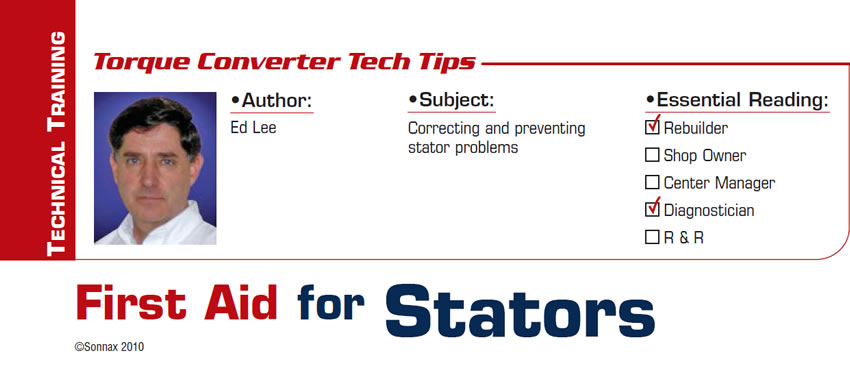

When the outer race of the one-way clutch became loose in the stator, rebuilders of the day faced a far-more-difficult challenge. The splined area on the outside diameter (OD) of the outer race broached a mirrored spline on the inside diameter (ID) of the stator when it was originally pressed into place (Figure 1).

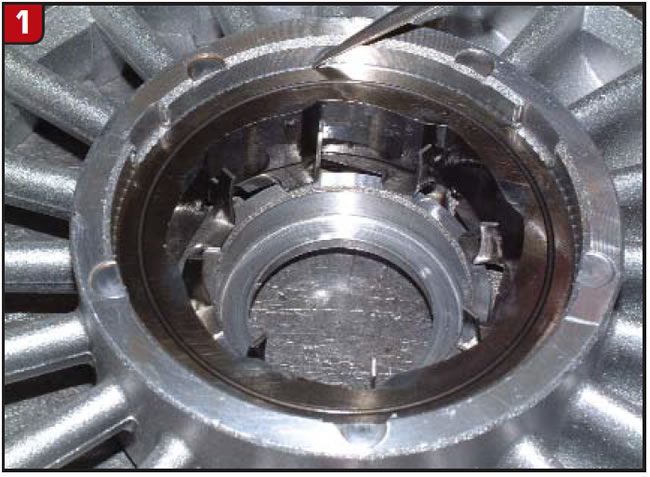

The broached spline worked well for the low-output torque of early vehicles. As engine-output torque increased over the years, more of the stators needed servicing. The rebuilding industry recognized the need for “fresh metal” to retain the outer race in the stator and responded in several ingenious ways. The most popular repair was called “pinning.” This repair involved machining a round hole with half the diameter in the stator and half the diameter in the outer race (Figure 2). The hole was then filled with steel round stock of the proper diameter (Figure 3).

The OE torque-converter manufacturers responded to this problem by adding lugs to the OD of the outer races. The outer races with the lugs may be retrofitted by milling slots in the ID of the stator bore. Both of these fixes were viable because the early converters were not restrained by present-day size limitations and stator walls were thick enough to be machined and still retain their strength.

Unfortunately, engineers now have to design converters to operate in smaller and smaller spaces. This size limitation has made converters flatter and also has narrowed the side walls of the stators. For this reason more converters are being built without the lugs on the OD of the outer races. As history would have it, the problem of stator races again becoming loose is a growing issue.

Since the wear rate between the outer race and the stator accelerates as the gap becomes larger, preemptive action is important. One preventive measure is to secure the race to the stator before the wear starts. Over the years, this has been accomplished by using a high-strength sleeve-retaining compound, such as green Loctite® 609. These compounds are designed to retain cylindrical assemblies. Their primary use is to secure cylinder sleeves in engines, but their high sheer strength (3,000 psi) and suitable temperature rating (300°F) make them very suitable for securing the outer race to the stator.

Suitable for gaps up to 0.005 inch, their low viscosity makes these compounds the best choice for securing an outer race that is still tight in the bore, and they can be applied without removing the race (Figure 4).

Alternative compounds with larger gap-fill ranges (up to 0.015 inch) are a better choice for an outer race that is slightly loose in its bore. The one downside of using these compounds is that, even though the initial set may take only 10 to 30 minutes, the full cure time can be as long as 24 hours. The long cure time prevents the immediate use of the part. To speed the cure process, some shops heat the parts in a small oven (Figure 5).

This can help obtain an acceptable cure in 20-25 minutes at 250°F. A small toaster oven will do one or two stators, and a turkey-sized toaster oven will do more when equipped with a rack.

If you can twist the race slightly within the stator bore before it becomes tight, you must preload the race before securing. To do this, hold the stator and rotate the outer race in the direction of engine rotation. If the race is extremely loose or can be rotated in the stator bore, it is too late; nothing will save this pair.

Ed Lee is a Sonnax technical specialist who writes on issues of interest to torque-converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.

©Sonnax2011