R&R Tech

- Author: Barry Bartlett

- Subject Matter: 2008 Dodge Ram 5500 with AS68RC

- Issue: Transmission limp mode

2008 Dodge Ram 5500 with AS68RC

We’ve all had to contend with intermittent electrical problems. These are typically the most difficult issue to pinpoint, as the root cause literally plays hide and seek with you. The following issue that I encountered belonged to a 2008 Dodge Ram 5500 in which the customer stated the transmission wasn’t shifting, and the check-engine light was on.

After some initial diagnosis, I noted that code P0778 was setting for the linear solenoid B electrical circuit. When this code sets, the transmission goes into limp mode and will not come out with a key cycle. The only way to get out of limp is to clear the code. The questions I always consider are what are the possible causes, and how will I test them?

I did some research on this AS68RC transmission to find out operating and circuit specs along with all the possible causes of the code. I found that there was not much information on this code other than an electrical issue and could be internal or external wiring, the solenoid, or the computer. I decided to start with the easiest thing to test, which is the wiring circuit. I like to test the entire circuit at the computer connector first so that I can see the complete circuit resistance, and if I see a problem I can narrow it down from there.

I went to pins 8 and 9 at the ‘C’ connector of the TCM and checked ohms through the circuit. The spec calls for 5.5 to 7.5 ohms on the linear PWM solenoids, and 14 to 16 ohms on the on/off solenoids. The circuit tested at 6.4 ohms, so all looked good. I compared it to linear solenoid ‘D’ with the same reading. I also like to load test the circuit which can reveal a poor connection, so I powered up the solenoid and when I momentarily grounded it, the solenoid pulled about 1.9 amps. I compared this to a draw test on solenoid ‘D,’ which is also a PWM solenoid with the same specs. I then monitored resistance on solenoid ‘B’ while moving wire harnesses and connectors, and there was no variation.

After several miles of road testing with no code set, my feeling was that the solenoid or internal harness was the problem, so the decision was made to replace the internal wire harness and solenoid with a new one. Chrysler sells all the solenoids together in a package, but we found that the Allison linear solenoids are interchangeable. The AS68RC solenoid ‘B’ is a normally closed solenoid, and a GM part #29533074 can be used to replace it. The linear solenoids ‘A,’ ‘C,’ and ‘D’ are normally open, so they would require a different part number.

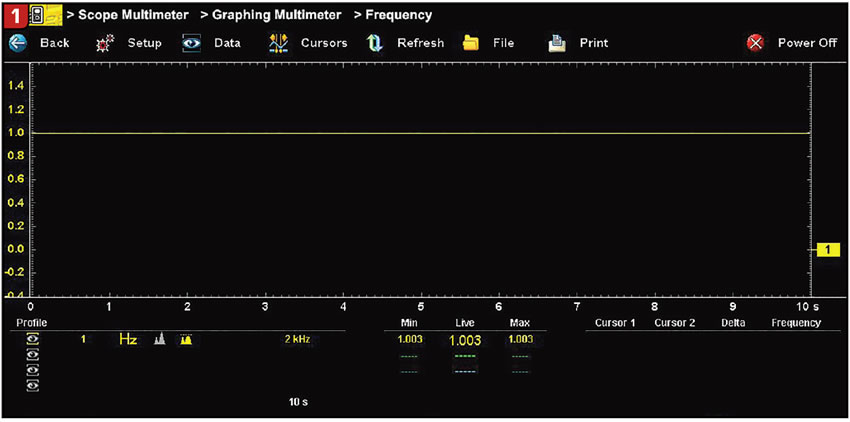

About 3,000 miles and several months later the truck returned with the same P0778 code and in limp mode. Awesome. Now we know the concern is intermittent. Since the linear solenoids are PWM solenoids I wanted to look at the pattern on screen and see what the trace looked like. So I got out our Verus Pro and went to the lab scope, but when I looked at it on the screen it just had a flat line voltage, but no PWM trace. I was puzzled by this, so I went to linear solenoid ‘D’ which in park should have the same readings, and again no PWM; just a flat line voltage (Figure 1).

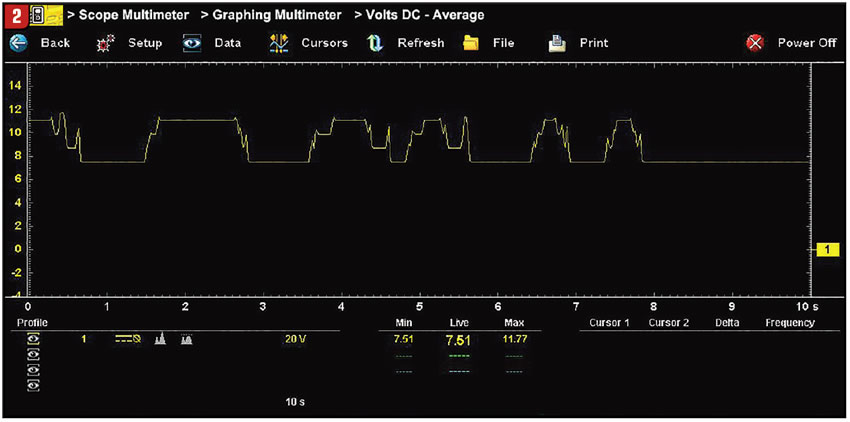

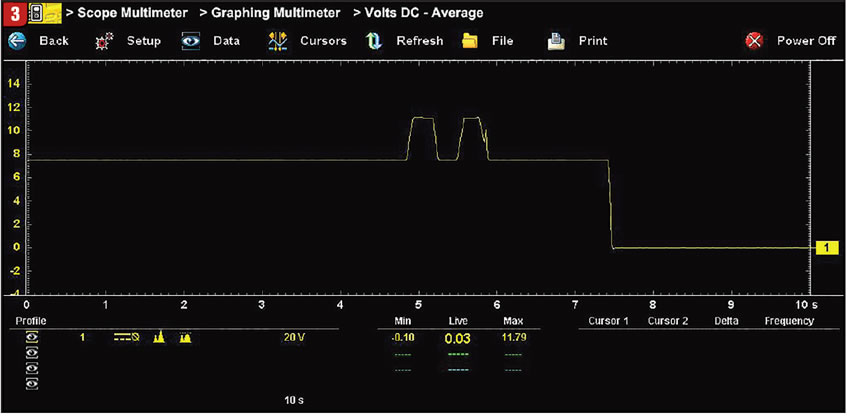

I noticed that the voltage would change going from park to reverse, to neutral and to drive. The voltage in park would be about 9.5 volts, in reverse the voltage would read about 12 volts, in neutral about 9.5 volts and in drive about 8.3 volts (Figure 2).

I measured the amperage compared to volts, the 8.3 volts was equal to .630 amps, the 9.5 volts was equal to 0.453 amps, and the 12 volt was equal to 0.134 amps. The high amperage (both 0.630 amp and 0.453 amp are in the high range) would open the pressure switch #2 and low amp (0.134 amp) will close the #2 pressure switch.

I then wondered if the computer was controlling some kind of variable resistance or voltage on the negative side of the solenoid. I thought I would look at the Hz to see if I could measure any fluctuation of the signal, and was surprised to see that it was pulsing the signal at 1003 Hz and was so fast that the scope was not picking up the wave form in the signal until I set the time scale to 200ms. I went to the voltage graphing screen on the scope because it will let me see up to several minutes on the screen so that I could monitor the voltage signal on a test drive.

I monitored the solenoid and on several test drives of about 60 miles I found the right combination to get the code to set. I found that when I made a right-hand turn on acceleration and hit a bump the signal on the negative side dropped to zero volts, the P0778 code set, and the transmission went into limp mode. Finally, the truck was showing its cards. I could duplicate this same scenario several times now, so I knew what condition was causing the code to set and during all the miles of driving the voltage signal on the positive side was steady with no variance, and on the negative side it changed correctly with the commanded shifts. I determined that the problem had to be in the external harness (Figure 3).

I made an insulated pair of twisted wires to run from the computer to the transmission and secured them in place, and after several miles of road testing, no more problems arose. The truck has now been gone for several months and no issues, so I can confidently say that it is now fixed.

As we would always hope, it would have been much more convenient for all had the issue been reproduced on the customer’s first visit. With intermittent problems we’re at the mercy of the gremlins, so sometimes the extra effort pays off when you know that the issue is, in fact, intermittent. That’s not always apparent the first time around.