Issue Summary:

- Dodge and Jeep trucks with 5.9-liter Cummins diesel engines may experience premature converter-clutch failure.

- Some RE and RH transmissions (the 500/518/618 transmissions with or without a governor-pressure solenoid) may experience a premature low/reverse-band burnout immediately after overhaul.

- Some 1996-99 vehicles equipped with the 42-47RE transmissions may exhibit a continual trouble code 1762 – governor-sensor offset volts or drift too low or too high – before or after overhaul.

- 1989 and later A518, 46RE and 47RE units may exhibit a late or no shift into third under various temperature conditions.

- Chrysler Corp. redesigned the housing for the rear (direct) clutch on the A500 (42RE) transmission during the 1998-99 model years on some models.

Dodge and Jeep vehicles with 5.9-liter Cummins diesel engines may experience premature converter-clutch failure. The friction material of the failed converter clutch may then restrict or stop all lubrication fluid by clogging the cooler in the radiator, causing premature failure of the planetaries as well.

The premature failure of the converter clutch is the result of an accumulation of causes, the first being excessive tolerance levels in the converter making it very loose internally. Second, there is a great speed difference between the turbine and the impeller at the time the clutch is applied. Third, there are damper-plate springs that load up to more than 2,000 pounds of tension when the clutch is applied during pulling conditions. When deceleration occurs, the energy from the springs releases in the opposite direction of engine rotation.

Incorporate these conditions with perhaps the use of a Jake brake, engine speed trying to go to idle, converter clutch releasing and the weight of the vehicle, and a momentary tie-up (torque reversal) occurs with all the stress being transferred to the converter bolts. The pads attached to the cover flex slightly, dimpling the internal clutch surface. With the clutch surface slightly dimpled, apply pressure drops as it leaks past the clutch into the exhausting release circuit. All these conditions working together result in premature failure of the clutch, with its fragmented material finding its way into the cooler and valve body. This also leads to the unpleasant experience of a clogged cooler and planetary failure.

Ideally, the correction is to have a customized converter made in which the internal tolerance is brought down to a minimum and a change made to the fluid-coupling characteristics to lessen the speed differential and torque-reversal stress on the pads. Then, making modifications to the valve body to provide increased converter-clutch apply pressure during peak load conditions becomes profitable. Care must be taken here as well, because if line pressure is elevated enough to increase converter-clutch apply pressure, a code P1763 – “Governor Pressure Sensor Volts too High” – may be set.

Some RE and RH transmissions (the 500/518/618 transmissions with or without a governor-pressure solenoid) may experience a premature low/reverse-band burnout immediately after overhaul.

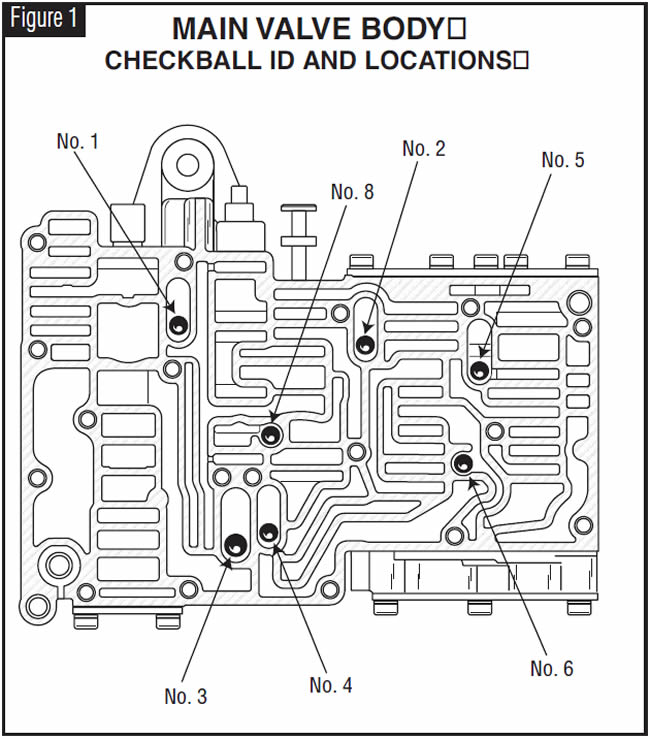

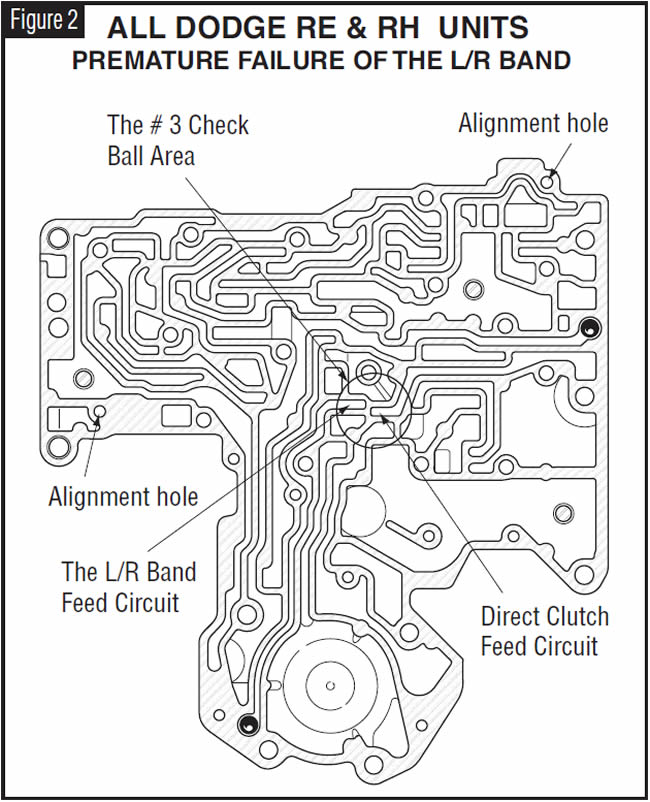

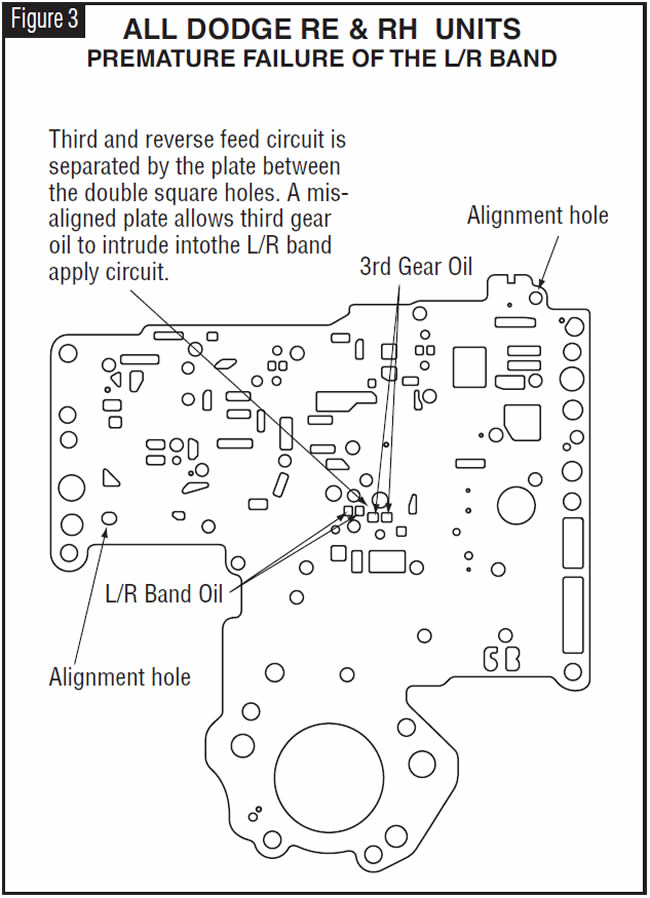

One such cause may be a cross leak between the spacer plate and channel plate near the area of the No. 3 checkball seat (see Figures 1 & 2). The cross leak may be the result of the spacer plate and channel plate being aligned incorrectly. This misalignment may allow minimal 3rd-gear oil pressure to cross over and intrude into the low/reverse-band circuit after a 2-3 shift has occurred. This minimal pressure is enough to make the band drag on the low drum in third and fourth gears, causing the premature failure of the band.

If the band is destroyed, the unit obviously will need to be removed for service. During the transmission-repair procedure, disassemble the valve body and carefully flat-sand the channel plate to ensure that the channel plate will mate flat to the spacer plate. During assembly of the valve body, there are two holes that are to be used to align the spacer plate properly to the channel plate (see Figures 2 and 3).

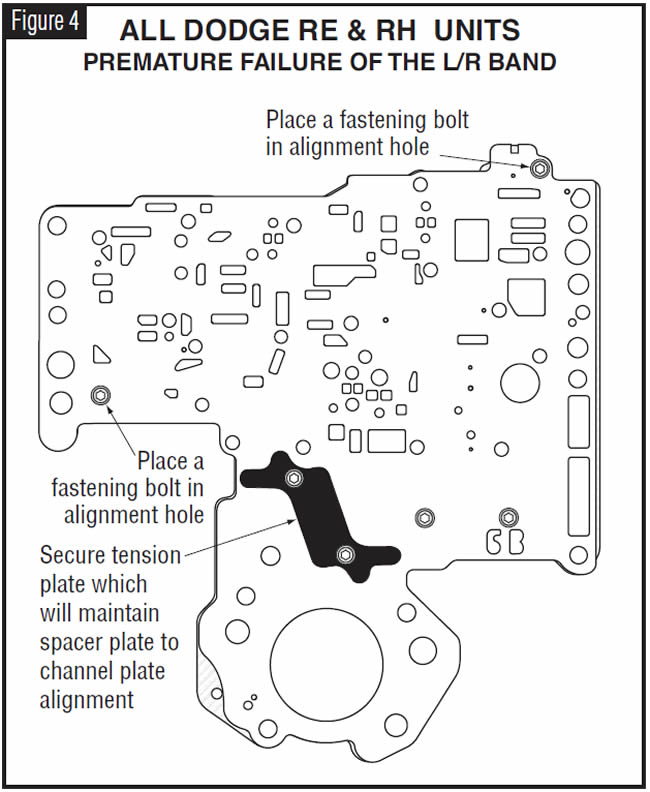

Place the spacer plate onto the channel plate and install the two bolts, one in each alignment hole, by hand. Then put the tension plate in place and tighten to 35 lb.-in. to secure the spacer plate to the channel plate (see Figure 4).

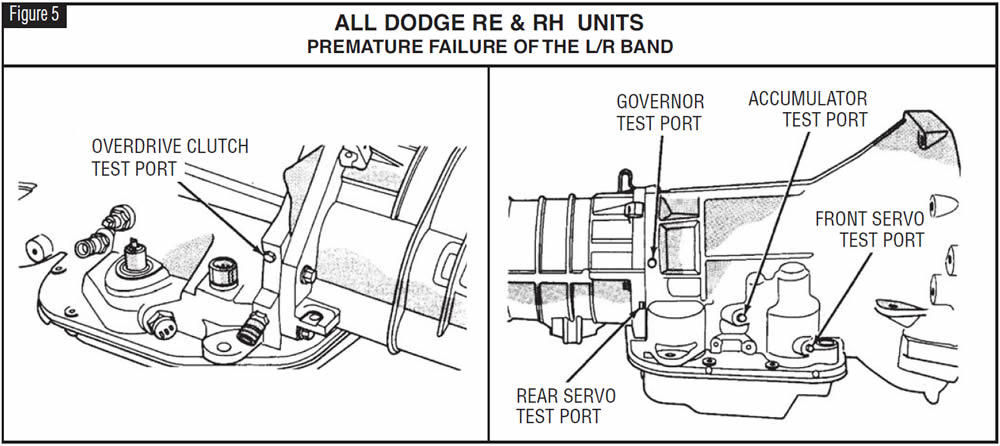

Remove the two bolts used to align the plate, re-use the same bolts to align the valve body, and torque all the attaching bolts to 35 lb.-in. After the unit has been repaired and re-installed, attach a pressure gauge to the low/reverse pressure port (see Figure 5) and ensure that 0 psi is present in third and fourth gears.

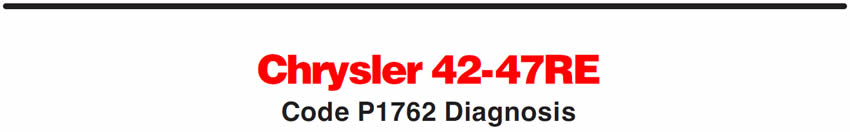

Some 1996-99 vehicles equipped with the 42-47RE transmissions may exhibit a continual trouble code 1762 – governor-sensor offset volts or drift too low or too high – before or after overhaul. This means that governor pressure, which is determined from the governor sensor, is higher or lower than the amount the computer has commanded.

The cause may be:

- A defective governor-pressure solenoid causing pressure to be too high.

- A defective governor-pressure sensor.

- An open or shorted wire from the ground wire leading to the governor-pressure sensor (see the note in Figure 6).

- A system-voltage overcharge, due to an alternator problem, causing the 5-volt feed to the sensor to be closer to 6 volts. This can cause the signal-return voltage to be higher than 0.76 volts when the selector is in Park or Neutral.

Refer to the corrections below to repair this condition.

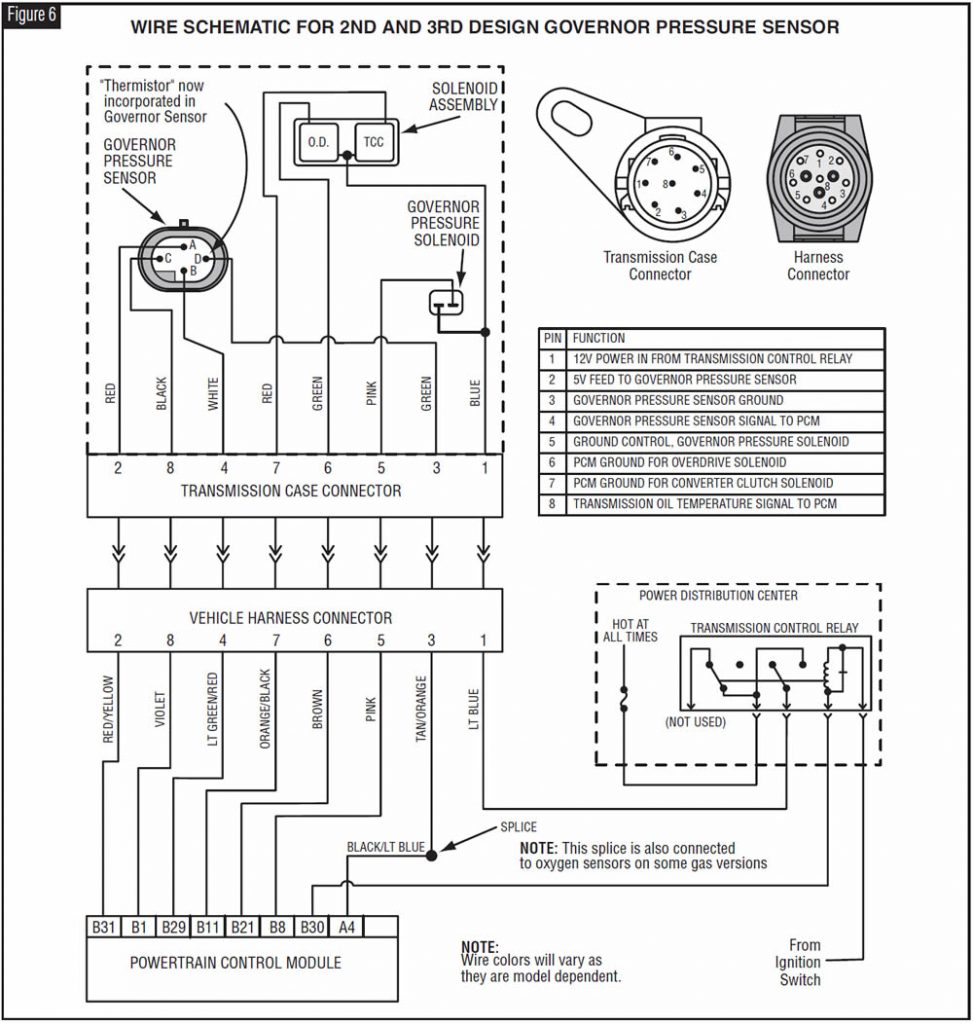

To verify the operation of the governor-pressure solenoid: Connect scan tool to OBD-II connector and monitor the Governor Pressure Desired parameter. This reading is the command line to the governor solenoid and should be the same as the Governor Pressure Actual parameter.

Example: If the Desired is 0 at 0 mph and the Actual is 20 psi, refer to Figure 7 and connect a 0- to 100-psi gauge to the governor-pressure port. If the pressure gauge reads 20 psi, this will indicate that the pressure solenoid is not doing its job and must be replaced.

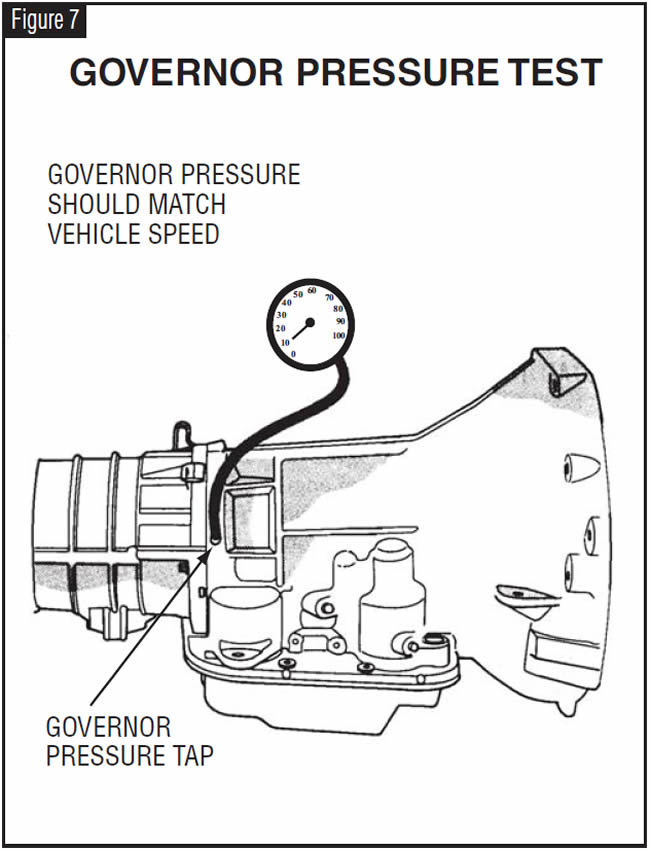

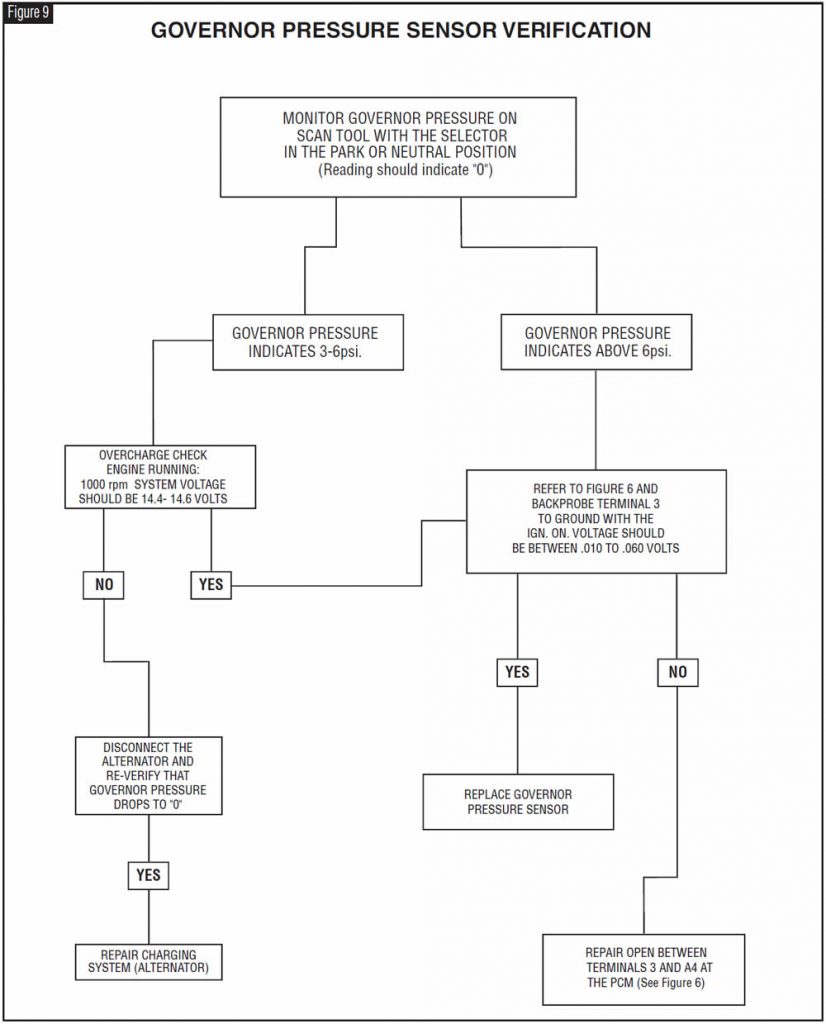

Refer to Figure 8 for identification of the governor-pressure sensor and Figure 9 to verify the operation of the sensor.

- Governor-pressure solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . .4617210

- Governor-pressure sensor (’96-99) . . . . . . . . . . . . .(90°) 56041403-AA

1989 and later A518, 46RE and 47RE units may exhibit a late or no shift into third under various temperature conditions. This complaint also may be accompanied by a delayed engagement into reverse when the transmission is hot.

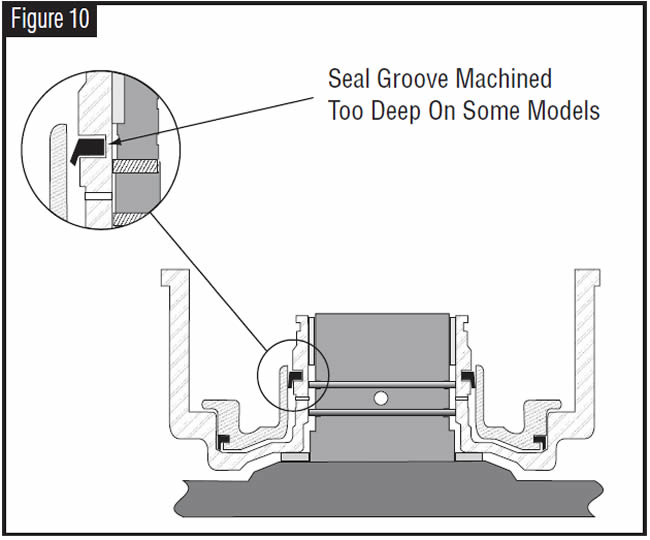

In some direct-clutch drums, the inner-seal groove was cut too deeply. This allows for the inner seal to be swallowed up into the groove, causing poor retention of fluid (see Figure 10). Another possibility is the outer lip seal being worn because of a poor finish on the drum in the contact area.

Replace the inner lip seal with a larger radial base. Aftermarket sources such as TransTec/Freudenberg-NOK and Precision International produce a wider-base seal to accommodate the deeper groove. Also, Shift Technology Products packages an inner lip seal in its K500-618 kit. Replace the outer lip seal after polishing the drum surface in the contact area of the outer lip seal.

There also have been reports of the same complaint with the inner lip seals on A500 and 42RE-style units. In these cases, a lip seal from a 200-4R servo has worked very well in this location.

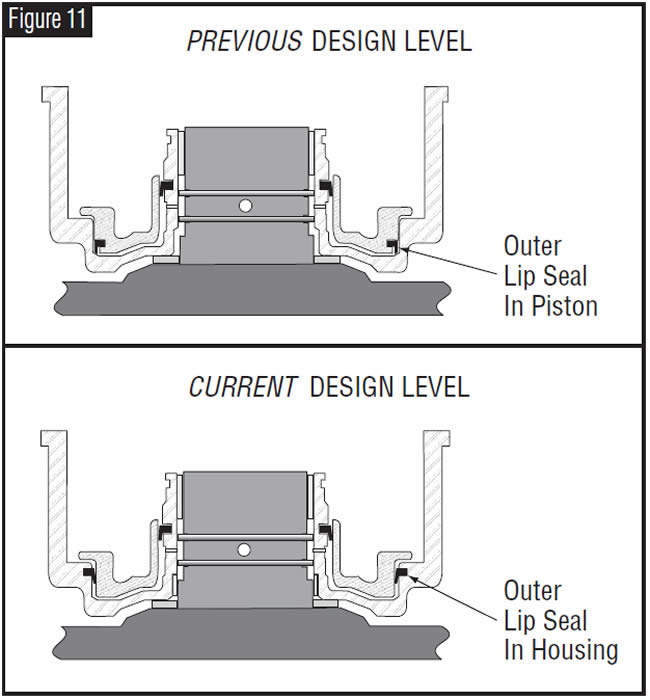

Chrysler Corp. redesigned the housing for the rear (direct) clutch on the A500 (42RE) transmission during the 1998-99 model years on some models. This clutch is applied in 3rd gear and reverse. Refer to Figure 11 for cutaway illustrations of both previous- and current-design housings.

Greatly improved application of the rear (direct) clutch and improved durability.

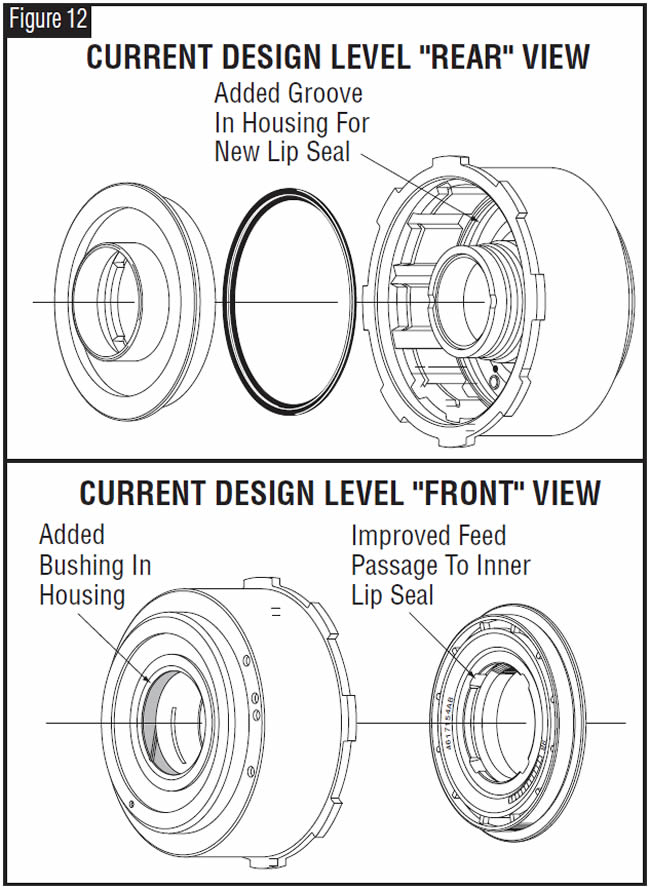

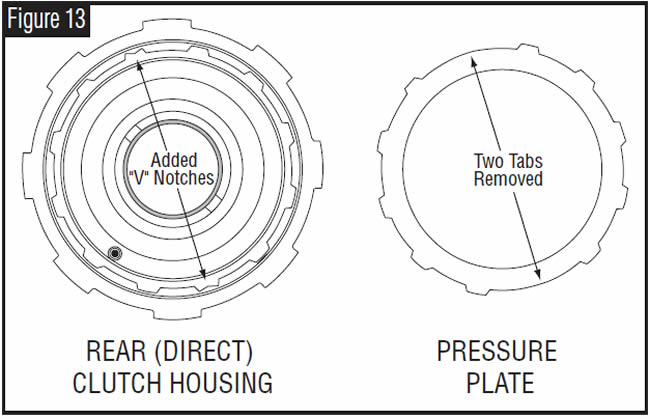

(1) Rear (direct) clutch housing – Now manufactured with the outer-lip-seal groove in the clutch housing instead of the clutch piston. Also, there is an additional bushing in the clutch housing to support the clutch housing when it’s installed on the pump cover, and V-shaped grooves have been added where the steel plates and pressure plate ride in the drum (see Figure 12).

(2) Rear (direct) clutch outer seal – Now an

inside-lip design, to accommodate the changes in the clutch housing (see Figure 12).

(3) Rear (direct) clutch piston – Now manufactured without the seal groove in the piston to accommodate the new seal in the housing (see Figure 12).

(4) Rear (direct) clutch pressure plate – Now manufactured with two of the locating tabs missing and must be oriented properly to fit into the clutch housing because of the added V-shaped grooves (see Figure 13).

None of the parts mentioned will interchange with any of the previous-design parts, but when used as a package they will retrofit all models of the Chrysler A500 (42RE) transmissions.

- Rear (direct) clutch housing (new design) . . . . . . . . . . . . . . . .4531285AB

- Rear (direct) clutch outer lip seal (new design) . . . . . . . . . . . .4058487AB

- Rear (direct) clutch inner lip seal (new design) . . . . . . . . . . . .2852925AA

- Rear (direct) clutch piston (new design) . . . . . . . . . . . . . . . . . .4617154AB

- Rear (direct) clutch pressure plate (new design) . . . . . . . . . . .4617176AB

February 2003 Issue

Volume 20, No. 2

- 5.9-Liter Cummins Diesel Trucks: Premature Converter-Clutch Failure

- All Dodge RE & RH Units: Premature Failure of the Low/Reverse Band

- Chrysler 42-47RE: Code P1762 Diagnosis

- Chrysler A518 Series: No or Late Third Gear

- Chrysler A500 (42RE) Series: New-Design Rear (Direct) Clutch Housing