Issue Summary:

- Incorrect installation of knock sensors can cause high line pressure and result in code 43 being stored on GM trucks and vans with gasoline engines.

- Using a long bellhousing bolt in a shallow hole when re-installing the 4T65-E in a 1999 or later Oldsmobile Intrigue can damage an engine-oil passageway.

- Watch your step in replacing the park/neutral switch on Cadillacs with 4T80-E transmissions. It can be tricky.

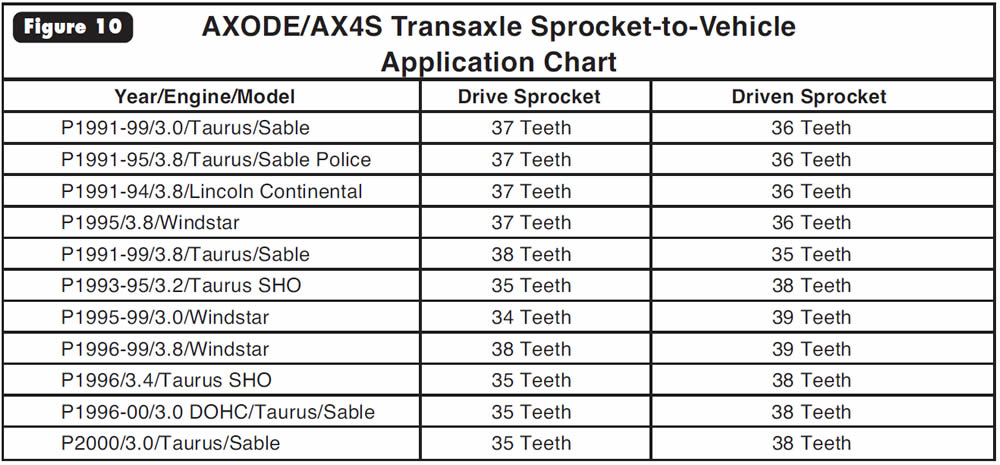

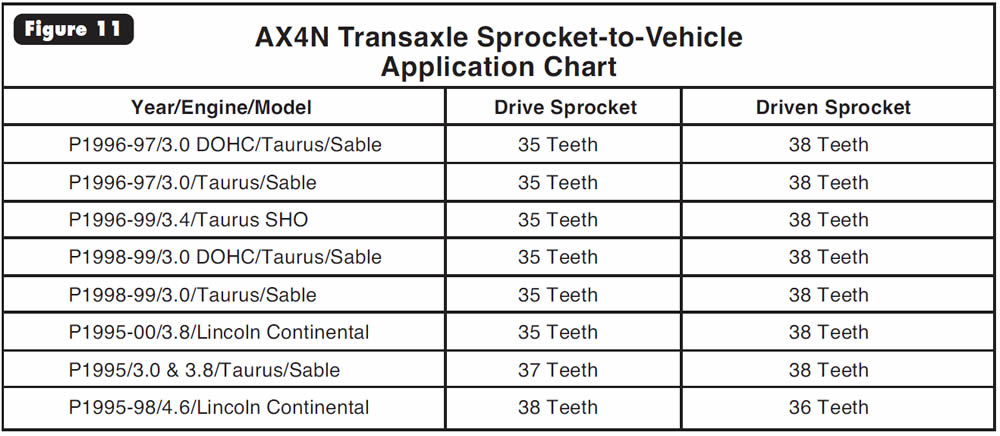

- Installing incorrect drive and/or driven sprockets on Ford AXODE/AX4S/AX4N can cause several fault codes to be stored.

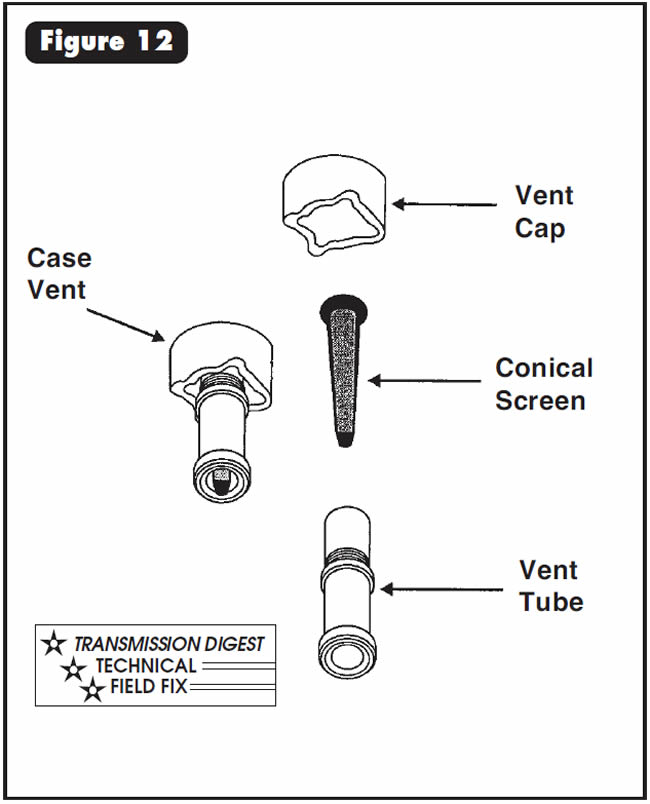

- Oil venting from the filler tube on Ford

AODE/4R70W could be caused by the conical screen in the case being blocked. - On a Chrysler A-518, no or late third gear may be because some grooves for the direct-clutch inner seal were cut too deeply into the direct drum.

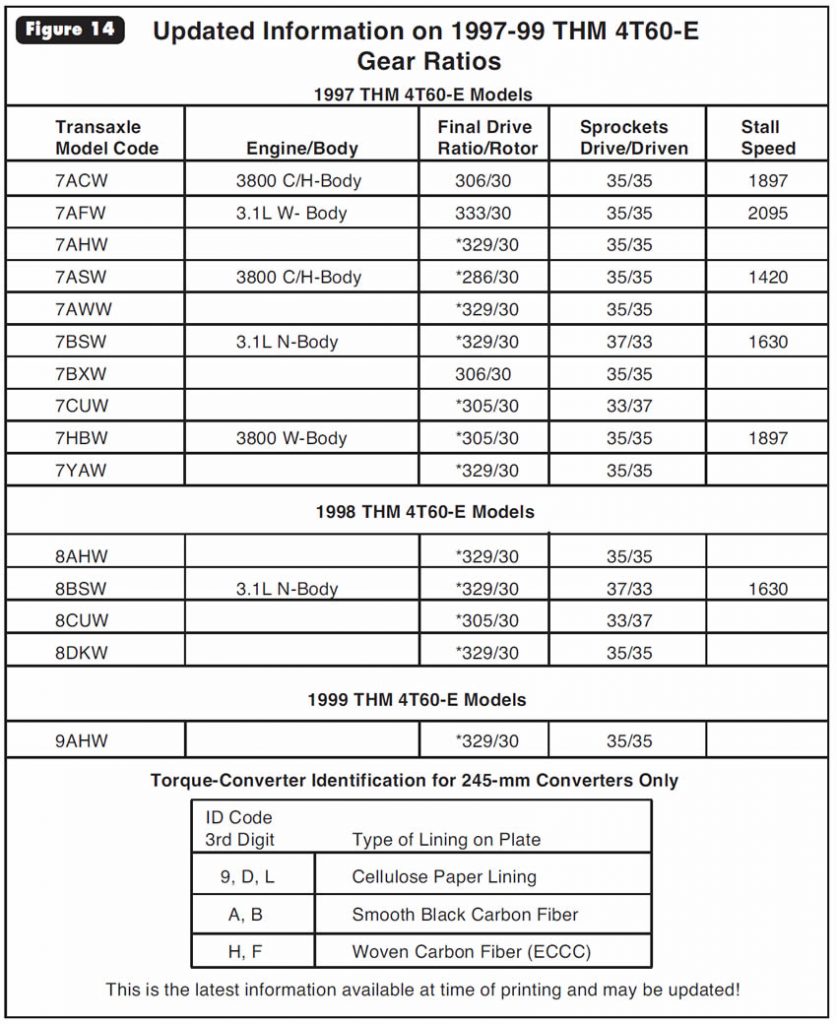

- We also have provided updated information on gear ratios for the 1997-99 4T60-E.

Harsh engagements and shifts, with storing of code 43 for a malfunction in the knock-sensor circuit.

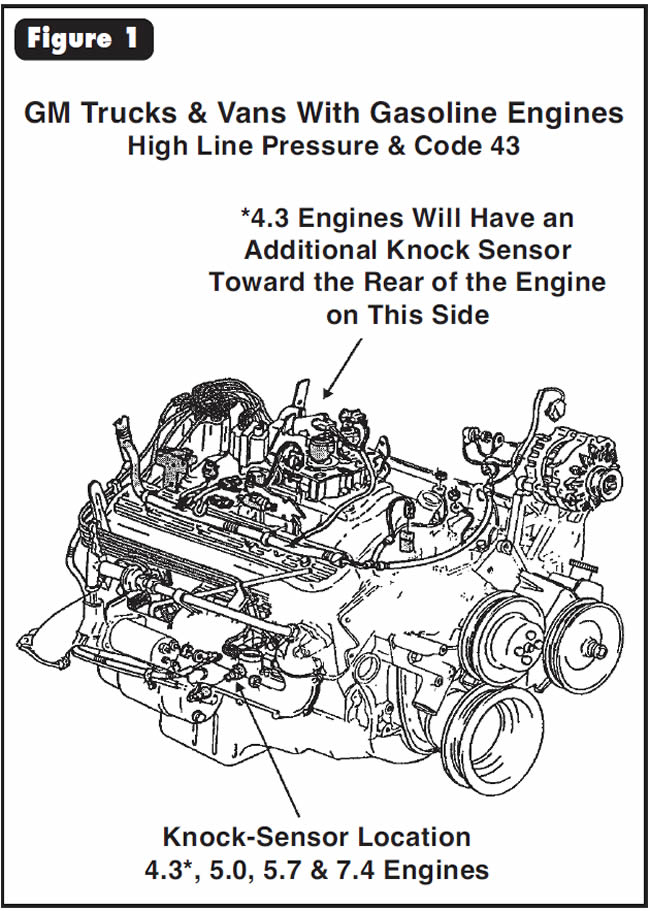

The problem usually begins with the knock-sensor wire having melted because the engine wiring harness was disturbed, leaving the sensor so close to the exhaust manifold (See Figure 1) that the wire leans against the exhaust manifold and burns through.

As a result of the wire damage, the knock sensor is damaged and requires replacement. After repair of the wire and replacement of the knock sensor, the high line pressure and code 43 still exist. The problem is that a knock sensor for a vehicle that requires dual knock sensors was installed mistakenly on a vehicle that uses a single knock sensor.

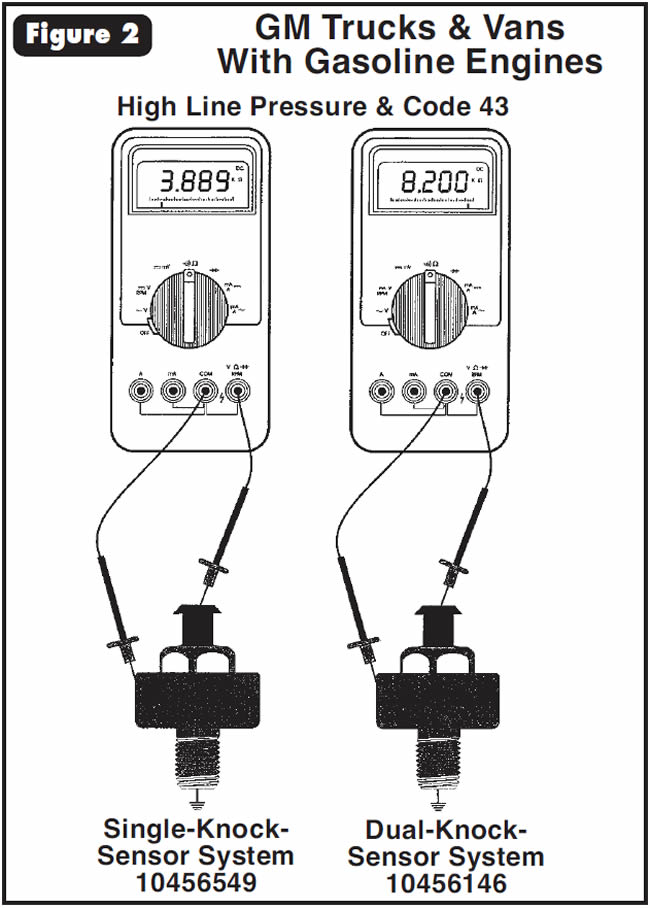

A knock sensor meant for a single-sensor application contains a 3,900-ohm resistor; one for a dual-sensor application contains an 8,200-ohm resistor (See Figure 2).

These two sensors are NOT interchangeable!

- Single-System Knock Sensor……………..10456549

- Dual-System Knock Sensor ……………….10456146

Many thanks to John Parmenter, Lee Myles Transmission, Centereach, NY.

An engine-oil leak has developed between the engine and transmission after re-installation of a 4T65-E in a 1999 or later Oldsmobile Intrigue with a 3.5-liter DOHC V-6 (VIN H) engine.

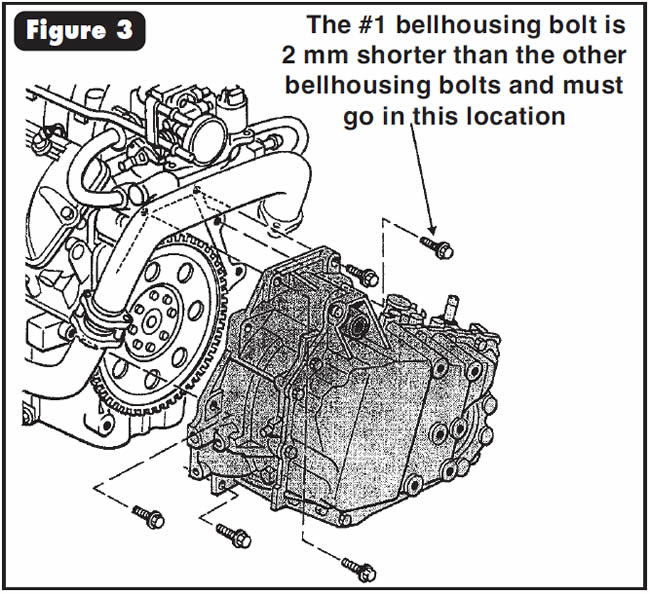

The No. 1 bellhousing bolt in this application is 2 mm (5⁄64 in.) shorter than the others (See Figure 3).

If one of the longer bellhousing bolts is installed in the No. 1 location, it will penetrate an oil passage-way in the back of the engine block, creating the complaint.

Make certain ALL installation personnel are made aware of this bulletin in order to avoid this catastrophe.

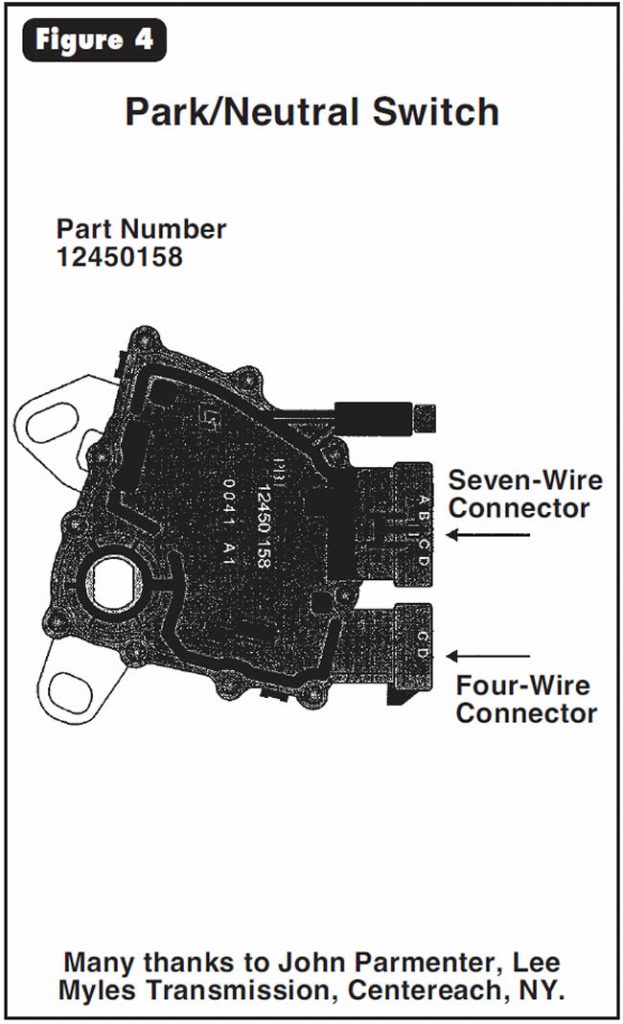

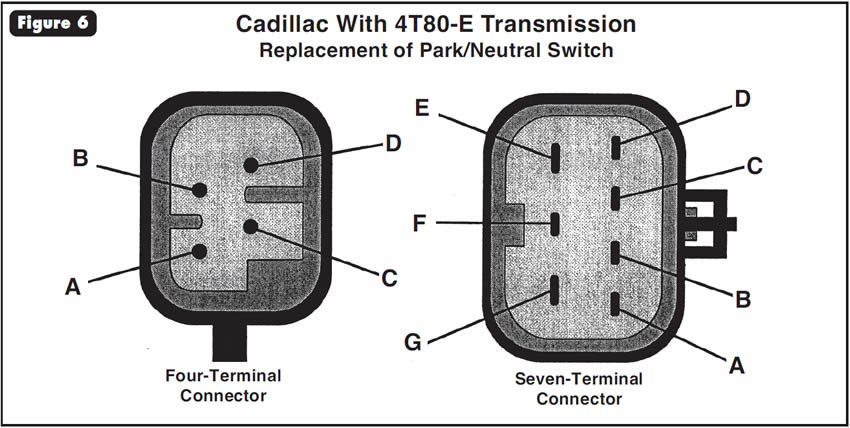

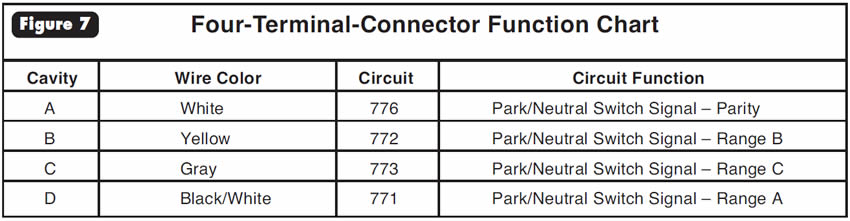

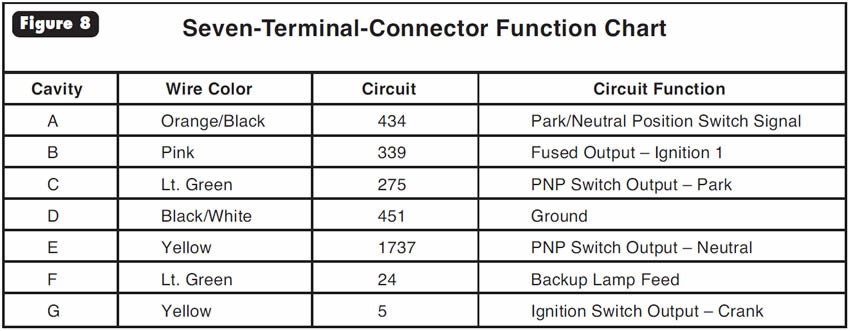

After replacing the park/neutral switch (See Figure 4), the technician is unable to attach the four-terminal connector to the new switch. It doesn‘t fit! When checking with the parts dealer, the technician is told that he must buy a connector-repair kit that will plug into the new switch. The technician now has to cut away the old connector, wire in the new connector, solder the connections and shrink-wrap the splices. As if that weren’t enough, all the wires in the connector-repair kit are white!

The new park/neutral switch has an added guide rail that the original switch did not have, which means the original connector does not have a provision for the added guide rail and will not plug into the new switch.

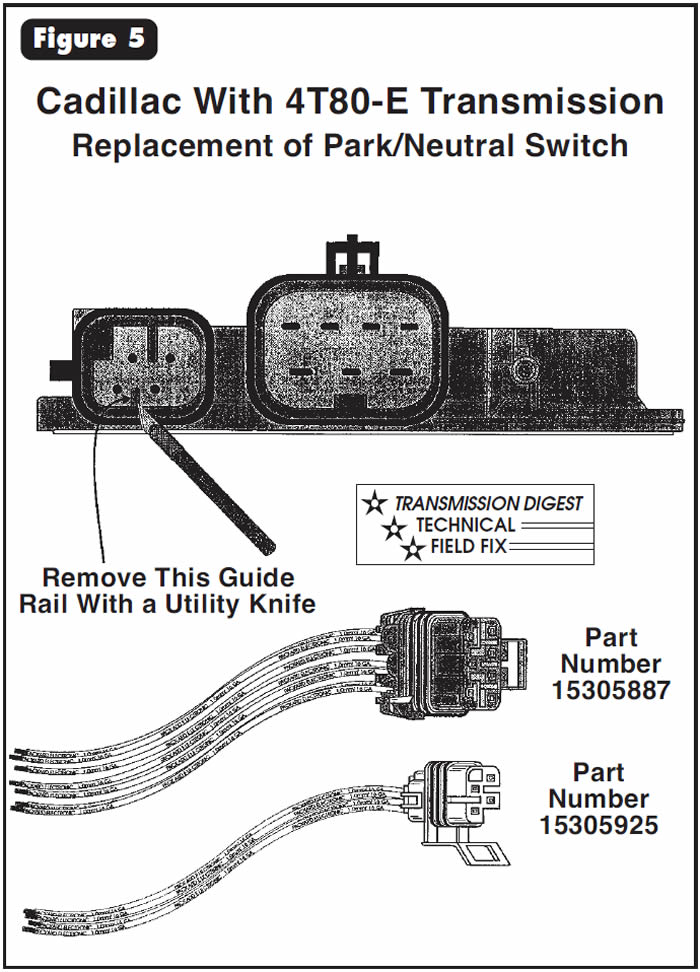

To avoid taking the time to rewire the connector for the park/neutral switch, unless necessary, remove the added guide rail in the new switch with a utility knife to allow the original connector to plug in (See Figure 5).

See Figures 6, 7 and 8 for identification and function of the terminals in the park/neutral switch.

Note:

A connector-repair kit also is available for the seven-terminal connector (See Figure 5).

- Park/Neutral Switch ……………………….12450158

- Four-Terminal Repair Kit …………………..15305925

- Seven-Terminal Repair Kit ………………….15305887

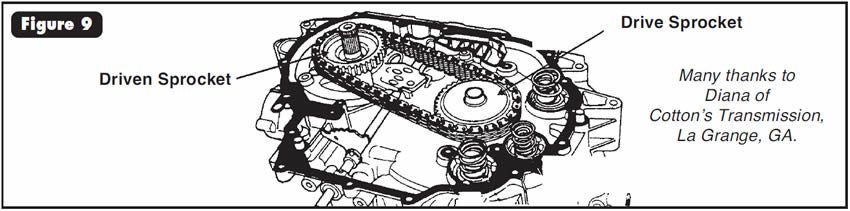

During the road test after an overhaul, the Malfunction Indicator Lamp (MIL) begins to flash and the system defaults to Failure Mode Effects Management (FMEM). When code retrieval is completed, code 628 for TCC slippage, code P0741 for TCC stuck off or code P1744 for a TCC performance fault may be stored. Diagnosis of the TCC system reveals no faults. When these codes are cleared, they return on the next road test.

These complaints can be caused by installing incorrect drive and/or driven sprockets (See Figure 9), or by installing an exchange unit that has an incorrect sprocket-tooth count. The sprocket-tooth count determines the target gear ratio that the PCM should see. Because the PCM is comparing the signals of the engine-speed and turbine-speed sensors, the PCM assumes that the converter clutch is slipping and stores the preceding codes because of an incorrect gear ratio caused by the incorrect sprocket-tooth count.

Use the charts in Figures 10 and 11 to ensure that the sprocket-tooth count matches the vehicle application. It also is a good practice to tag exchange units so that the sprocket-tooth count is known to ensure that the correct transmission for that vehicle is installed.

Note:

To help diagnose this problem, raise the front wheels off the ground and see whether these codes reset with no load on the vehicle. If they do reset, the chances are that it is a gear-ratio error and NOT converter-clutch slip.

After installation of the overhauled transmission, as oil is being pumped into the filler tube, it becomes difficult for the transmission to accept oil. As the transmission warms, oil begins venting from the filler tube. This problem was NOT an original complaint. A front-seal leak also may develop.

The transmission-case vent contains a conical filter screen (See Figure 12). While the case was in the cleaning machine, detergent residue or other contaminants became lodged in the screen and restricted it, resulting in the complaints.

When air-blowing the case after it comes out of the “cooker,” be sure to blow air into the vent to ensure that the vent is clear. If it is not clear, either remove the screen or replace the vent assembly. It is recommended that the screen in the vent always be removed.

Many thanks to Ed Lee from Deltrans Inc., Newark, DE.

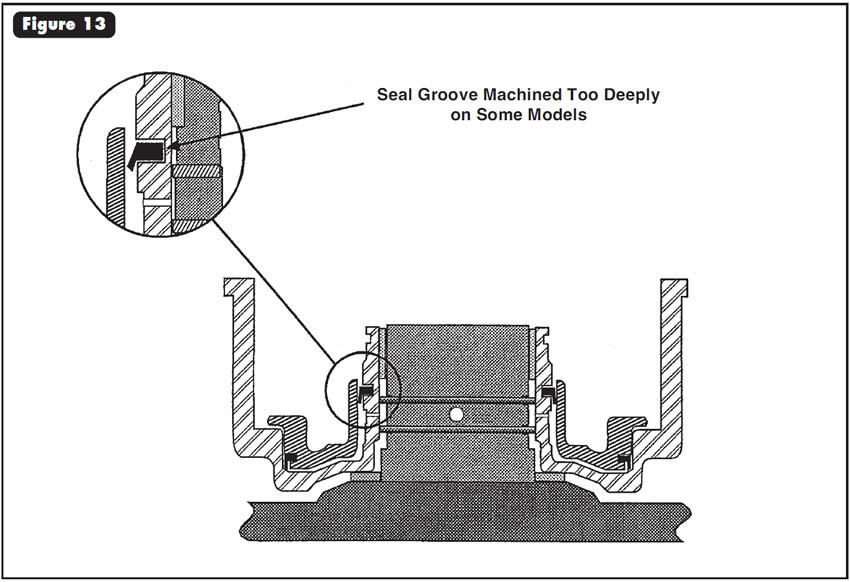

1989 and later A-518, 46RE and 47RE units may exhibit a late or no shift into third under various temperature conditions. This complaint also may be accompanied by a delayed engagement into reverse when the transmission is hot.

Some direct-clutch drums had the inner-seal groove cut too deeply. This allows the inner seal to be swallowed up into the groove, causing poor retention of fluid (See Figure 13). Another possibility is that the outer lip seal is worn because of a poor finish of the drum in the area where it contacts the outer lip seal.

Replace the inner lip seal with one that has a larger radial base. Aftermarket sources such as Freudenberg-NOK/TransTec and Precision International produce a wider-base seal to accommodate the deeper groove. Also Shift Technology Products packages an inner lip seal in its K500-618 kit. Replace the outer lip seal, after polishing the drum surface in the contact area of the outer lip seal.

There also have been reports of the same complaint with the inner lip seals on A-500 and 42RE units. In these instances, a lip seal from a 200-4R servo has worked well in this location.

Issue:

General Motors has updated information on gear ratios on the 1997-99 THM 4T60-E units (See Figure 14).

February 2001 Issue

Volume 18, No. 2

- GM Trucks & Vans With Gasoline Engines: High Line Pressure & Code 43

- 1999 & Later Oldsmobile Intrigue With 3.5L Engine and 4T65-E Transmission: Damage to Engine-Oil Passageway

- Cadillac With 4T80-E Transmission: Replacement of Park/Neutral Switch

- Ford AXODE/AX4S/AX4N: Gear-Ratio Errors

- Ford AODE/4R70W: Oil Venting From Filler Tube

- Chrysler A-518 Series: No or Late Third Gear

- THM 4T60-E Gear-Ratio Update