Technically Speaking

- Subject: Harsh engagement, failsafe, solenoid codes stored

- Unit: TAAT

- Vehicle Application: 1995 Saturn

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

Electronic failure can be very similar to a mechanical failure in that when one thing goes wrong, it can cause another part to fail. If you are not careful, you could make a repair that doesn’t fix the original cause of the failure, leading to a repeat failure after repairs.

Recently, a shop in town had a 1995 Saturn with extremely harsh engagements. It was also in failsafe with a host of actuator (solenoid) codes. It is not unusual for the solenoid case connector or conductor plate to fail, causing these codes. Upon a visual investigation these items proved to be good (see Figure 1).

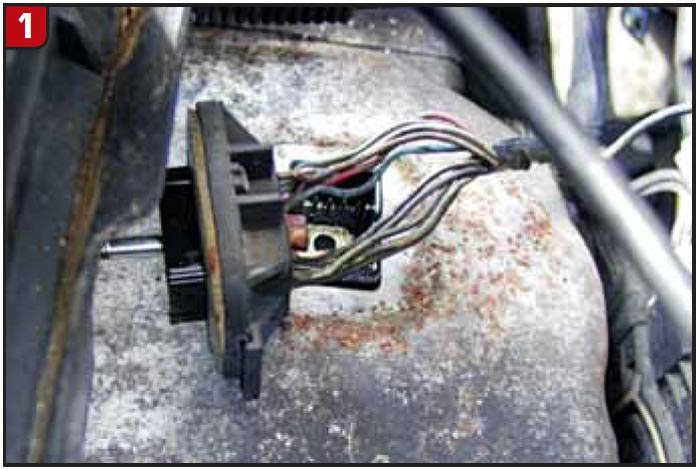

A voltage test was performed on the ground side of each of the solenoids at the PCM (see Figure 2). With the key on, engine running, the test showed slightly less than 1 volt on each solenoid. With all solenoids off, there should have been system voltage on these wires. Voltage then is pulled down when the computer grounds the solenoid to activate it. But when they are off, system voltage should be present.

One thought that came to mind was that all shift solenoids are energized for first gear, so with the vehicle running in Park, maybe the PCM is grounding the solenoids in preparation for a shift into Drive. But that couldn’t be right, as these solenoids are pulse-width modulated and are not fully pulled to ground. Additionally, the TCC and PCS solenoids also had shown that they were being pulled fully to ground. In fact, you would normally see about 8 to 9 volts on the ground side when these solenoids are at their peak on-time duty cycle. So could the computer be bad? Maybe. But the next logical step would be to check the power side of the solenoids.

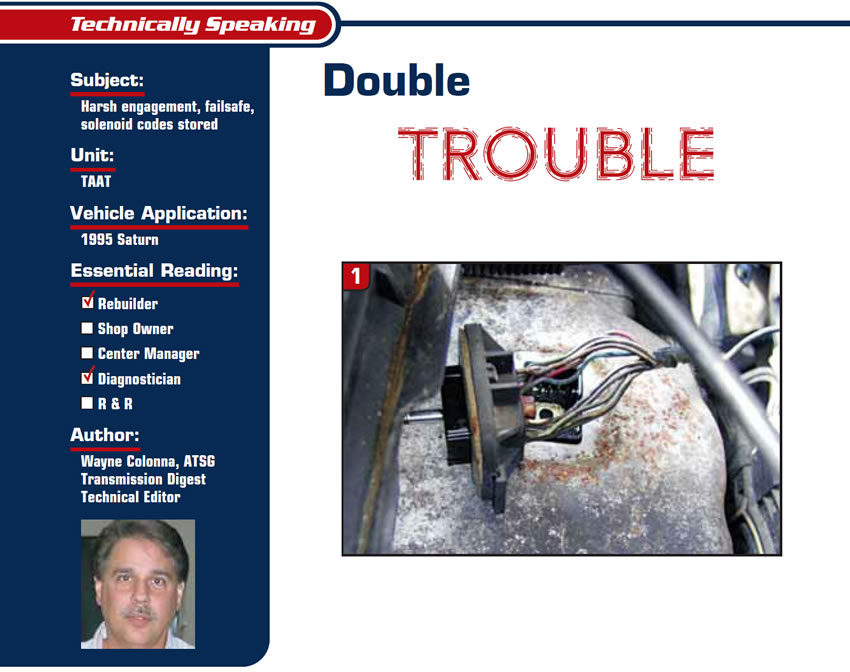

With this particular vehicle, there are three fuses in the underhood junction block on the left side of the engine compartment (see Figure 3) that supply voltage to all five solenoids. What you should see is full system voltage on the power side of the solenoids when the vehicle is running, regardless of whether the computer is grounding the solenoids. But what was seen was just slightly more than 1 volt. So it appears that we have a power-supply problem (see Figure 4).

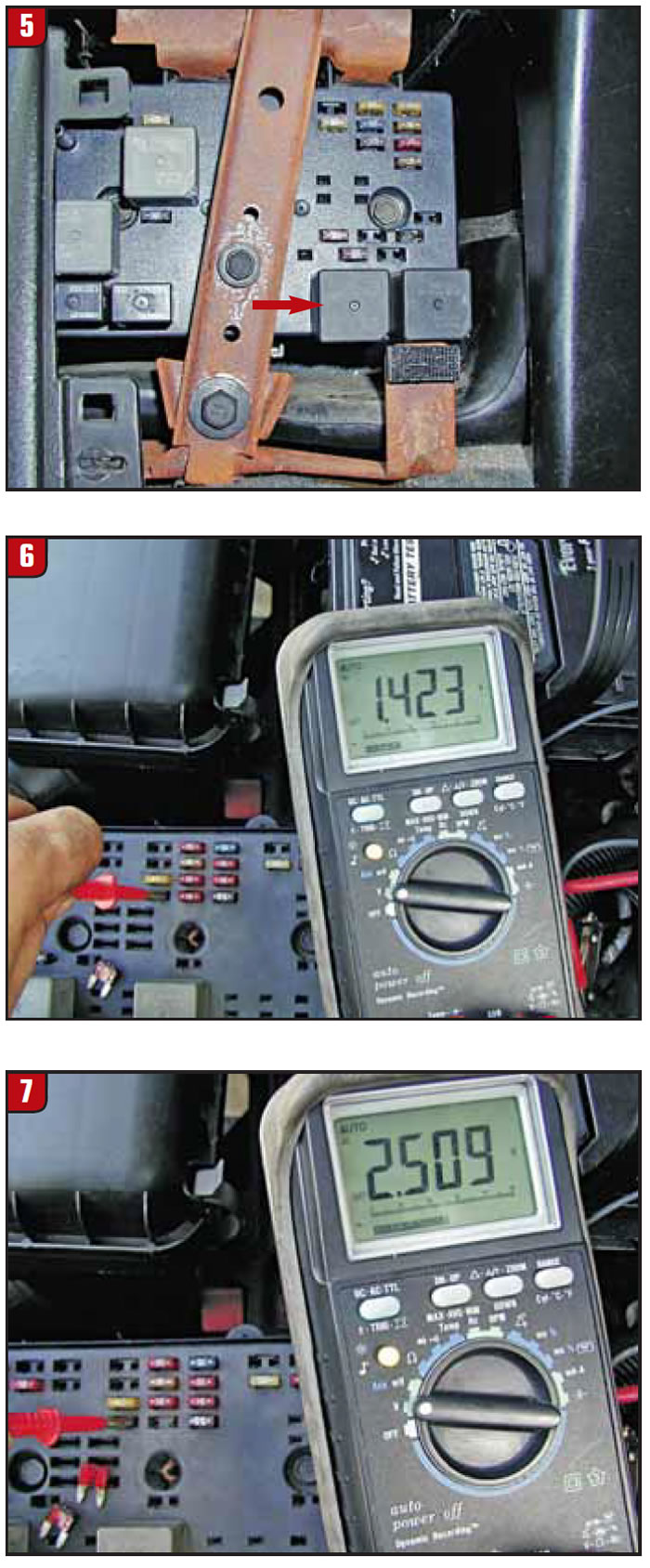

A wiring diagram was obtained, and it revealed that the power originates from a “hot at all times” 30-amp battery fuse (see Figure 3) also in the underhood junction block feeding power to a fuel-pump relay inside the car (see Figure 5). When the fuel-pump relay is activated, it sends power from the 30-amp battery fuse to the three solenoid fuses and into the transmission.

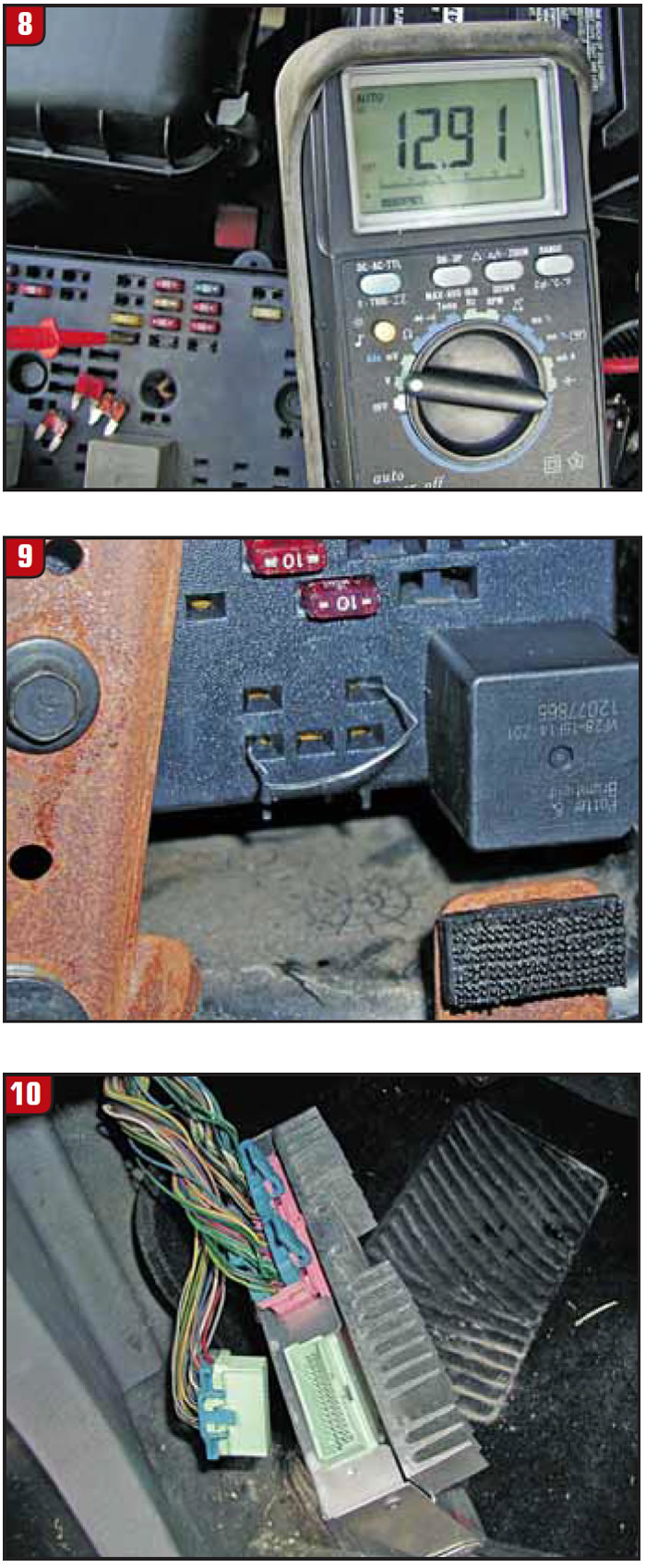

Another thought was, “Well, if the car is running, the fuel-pump relay must be working; how else could it run if it were not?” Out of curiosity, we pulled one of the solenoid fuses and checked the hot leg in the connector while the vehicle was running, and we saw 1.4 volts (see Figure 6). What an interesting surprise. We then pulled the second fuse and saw 2.5 volts (see Figure 7), and after pulling the third fuse we saw 12.92 volts (see Figure 8).

This was very strange at first, and it took us a minute to process the data. After we considered these results, there had to be two problems at play here. One was that the solenoids were being grounded when they shouldn’t be, and the other was that there had to be an unknown resistance problem on the power supply from the relay to the fuses causing such a voltage drop.

And then the light bulb went off! No pun intended, but a light bulb is a very good tool to check voltage-drop problems. What we have here is double trouble that originated with this compromised power supply. When the power supply began to have problems, the computer had to work harder to ground and operate the solenoids. Eventually the power problem caused the computer to burn out its drivers.

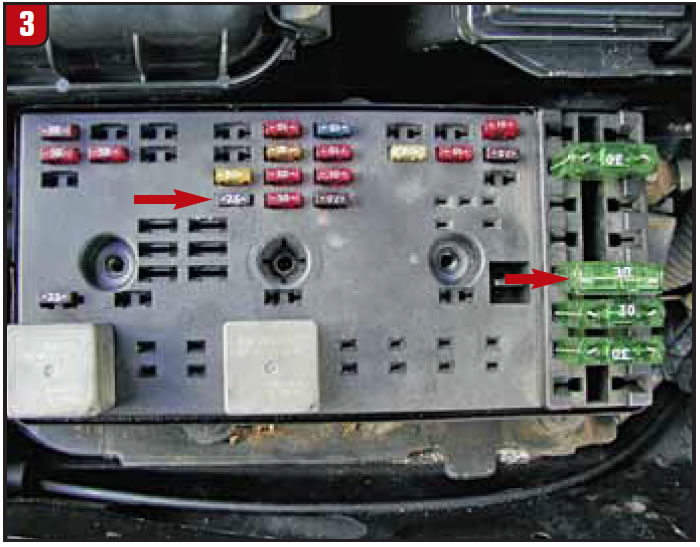

To verify that the relay was not a problem, we used a paperclip to jump the voltage from the 30-amp fuse directly into the circuit going to the fuses (see Figure 9). A volt-age check on the paperclip showed there was full battery voltage, yet when we again made a check at the fuses, we had the same voltage-drop problem, and this was with-out the vehicle running. The key was in the off position. When the computer was unplugged (see Figure 10), full voltage returned to the fuses (see Figure 11). A new wire from the back side of the relay panel to the underhood junction box (see Figure 12) and a new computer resolved the problem.