TASC Force Tips

- Author: Ed Lee, Deltrans

Most transmission shops try their best to do a good job for their customers. Unfortunately, there are times when good intentions are simply not enough to make a job turn out perfectly. This is just another example of what we all know happens when we assume.

A four-wheel-drive 1995 Dodge R1500 pickup was towed to a transmission shop, which performed the usual pre-checks, including checking codes, cooler flow, pressure, and function of the transfer case and both differentials. All preliminary checks pointed to the transmission as the problem, and its subsequent removal and inspection did verify a defective transmission. The transmission rebuild seemed to go routinely, and the transmission performed adequately on the road test.

The technician performing the road test noticed a noise when crossing a small bump in the road. It sounded like the noise that comes from a transfer case when the snap ring behind the bearing on the output shaft breaks. The technician called the customer and asked about the noise. The customer assured the technician that the noise was not there previously.

Assuming that the customer’s information was factual, and assuming that a broken snap ring caused the noise, the technician removed the rear driveshaft and the extension housing from the transfer case. However, the snap ring was intact. At this point, with the driveshaft and extension housing already out of the vehicle, it would be just as fast to remove the transfer case as to put the vehicle back together. The transfer case was removed and disassembled for inspection. The inside appeared to have little more than normal wear for the mileage, and the source of the noise remained a mystery at that time.

The vehicle was reassembled, and a more-thorough road check was performed. This time, the technician noticed that the noise would start when he hit the same bump in the road, and he also noticed that the noise would disappear if he pulled back on the transfer-case lever.

Very little movement was necessary to make the noise go away. The fact that moving the transfer-case lever made the noise change convinced the technician that the noise was originating in the transfer case and that he must have missed something during the earlier inspection.

When he removed and disassembled the transfer case for re-inspection, he found nothing new. Still convinced that the problem was inside, the technician thought it might help to throw some money at the transfer case. He replaced the chain and the range fork. He reassembled the transfer case with the new parts, and to no one’s surprise, the noise was still there.

Again the vehicle was taken on a road test, but this time the “Chassis Ear” was connected to the transmission, the transfer case and both differentials. This narrowed the noise down to the front differential.

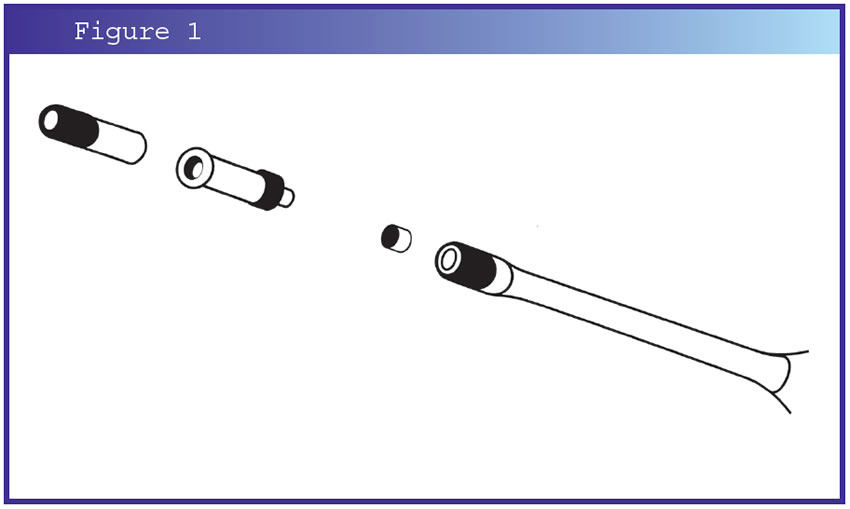

The diaphragm that engages and disengages the front axle is fastened to the axle with four bolts. By removing the four bolts you can pull the diaphragm aside, giving you an inspection window for the front axle. As soon as the technician gained access, the problem was obvious. The passenger-side axle has one part that is splined into the differential. A second part of the passenger-side axle is connected to the right-front wheel. Where the two parts of the passenger-side axle meet, a bushing centers the outer portion in the inner portion. On this vehicle, the cork gasket that keeps differential fluid from leaking out between the housing and the diaphragm had a leak at one lower corner. The fluid level in the differential was high enough to keep the differential from self-destructing, but too low for sufficient lube to the bushing where the axles meet.

The bump in the road would start the rattling between the axles, and moving the transfer-case lever would send the engagement command to the diaphragm, which would connect the axles and stop the noise.

You could ask for 10 suggestions on how this situation could have been handled better, and you probably would get 10 good ideas. Using the “Chassis Ear” earlier would be an excellent idea. Removing the front driveshaft and engaging and disengaging the front axle with a remote vacuum source will isolate the front axle from the transfer case. Not assuming that you know what the problem is before you have checked it out completely is the best idea of all.

The TASC Force (Technical Automotive Specialties Committee) is a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.