TASC Force Tips

- Author: Brian Workman

What does fuel trim have to do with loss of lockup in an A4LD?

After installing an A4LD, you take it for a road test and it works perfectly! Then, as you return to the shop, you lose lockup.

You break out your scan tool and there are no codes. No codes, no lockup. Why? The first thing you need to do is determine whether you have a control problem or a transmission problem. So, it’s off for another road test, this time to monitor whether the computer is commanding lockup. Sure enough, the computer is not commanding lockup.

Just to put your curiosity at rest, you override the lockup command and the transmission does have lockup. That’s a relief, huh? So why isn’t the computer sending a signal for lockup?

To start with, computers, as I always say, are “stupid.” Don’t give them any information and you get nothing in return. Give them limited or wrong information, and that’s what you will get back. Computers don’t think – they are processors, which means they process information and perform tasks. Lockup is one of those tasks. So why did we lose the command?

For a computer to perform a task, it must receive information from the sensors. Mass air flow (MAF), oxygen (O2), knock, manifold absolute pressure (MAP), air-intake temperature (AIT), crank and camshaft, vehicle speed, gear position, coolant temperature (CTS) and throttle position (TPS) are just some of these sensors. They send information to the computer, which then can command the actuators to perform their tasks. Actuators are solenoids, lockup, shift, EGR valves, fuel injectors etc.

What does fuel trim have to do with lockup? Nothing, but it has everything to do with drivability.

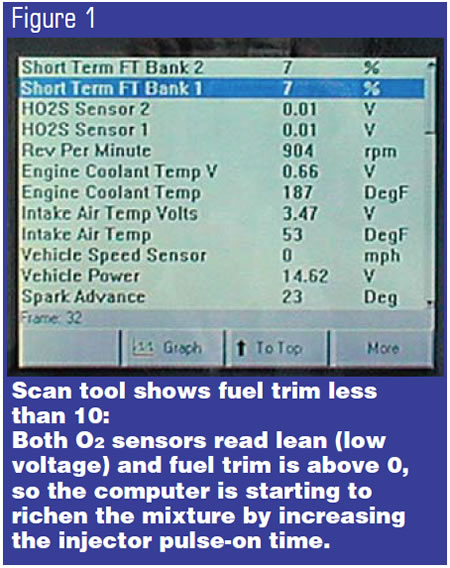

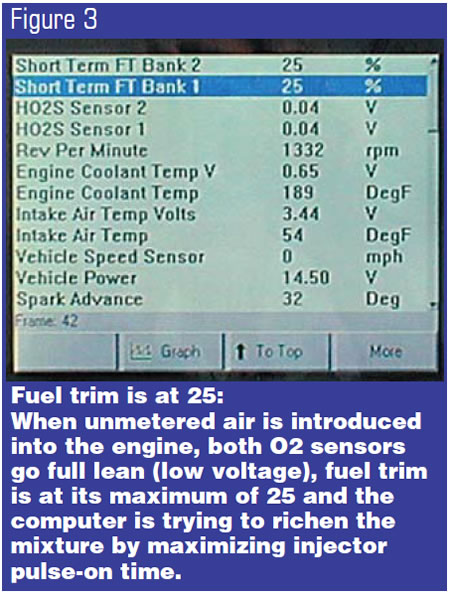

So what is fuel trim? Fuel trim is rebalancing the fuel mixture for reduced emissions. It is a number that represents the computer’s learned amount of total fuel need. That number is derived from the time the fuel injectors are pulsed on and off. The higher the fuel-trim number, the more fuel is being commanded, the more injector pulse-on time. The lower the number, the less fuel is commanded, the less the injector is pulsed on. The fuel-trim command is a result of what the oxygen sensor tells the computer. You don’t want to see short-term fuel trim over 10 on your scan tool. Fuel trim starts at 0 and can go positive (more fuel) or negative (less fuel).

The oxygen sensor’s job is to tell the computer how much unburned oxygen is in the exhaust. When the O2 sensor reads a high amount of oxygen, the voltage will be low, around 100 mv. This is a lean condition. The computer will add fuel to richen the fuel mixture by increasing the amount of time the injector is turned on.

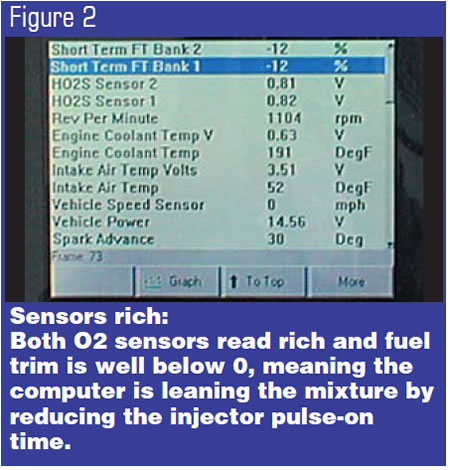

When the O2 sensor reads a small amount of oxygen, the voltage will be high, around 900 mv. This is a rich condition. The computer will reduce the amount of fuel by decreasing the injector on time.

Watching the O2 sensors on your scan tool, you’ll see the voltage switching continually between high and low, from 100 mv to 900 mv. If the O2 sensors are working correctly and everything is normal with the engine, the switching voltage will cross 500 mv rapidly.

Every time the O2 sensors cross the 500mv threshold, the computer makes adjustments, either increasing or decreasing the amount of fuel to the engine. This is fuel trim.

How does this help us in diagnosing a no-lockup condition? Easy!

Drive the vehicle and watch fuel trim. Short-term fuel trim should never go over 10. If it does, start looking at the O2 sensors’ voltage. If your O2s are reading lean, 100 mv or less, and fuel trim keeps rising over 10 to 20, 25 and more, the computer is telling you that no matter how much fuel it adds, it can’t make the system go rich. In these lean conditions, the computer will inhibit lockup to prevent a lean-mixture drivability problem, which shows up as lean misses or surges during driving. It can feel like a transmission going in and out of lockup.

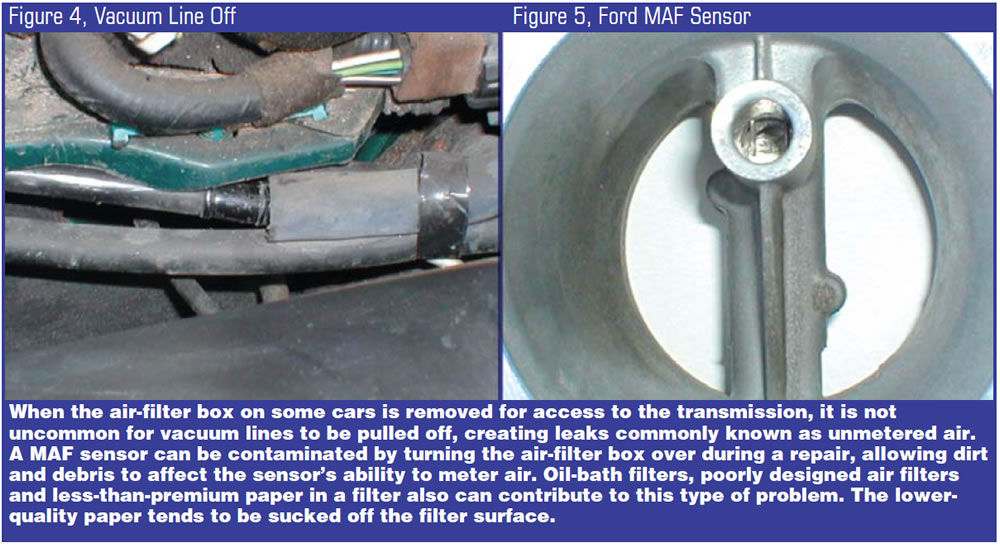

The most-common reason for high fuel-trim numbers and a lean O2 sensor is unmetered air. All air entering the engine must pass through the MAF. The computer reads the amount of air entering and controls the fuel injectors’ pulse-on time for a proper mixture. Any air that gets into an engine without being read by the MAF is called unmetered air. Unmetered air can be the result of several things: A dirty or contaminated mass airflow sensor, vacuum leaks, damaged intake tube from the air box to the throttle body or clamps to the intake tube left loose during installation. The MAF can become contaminated simply because of the air box being turned over with a dirty filter in it. On this particular vehicle, the mass airflow sensor needed to be cleaned and the air filter needed to be replaced. Problem fixed.

Brian Workman is an international technical consultant and an associate member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.