R&R Tech

- Subject: Slipping or bumpy shift

- Vehicle Application: 2002 Ford Explorer 4×4

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Chris Adams

A 2002 Ford Explorer came into our shop recently with a shifting complaint. The customer said it slipped or felt bumpy under fairly hard acceleration.

Our initial inspection starts with a road test to verify customer concern, a computer scan for trouble codes and a visual inspection. On the initial road test I had felt the condition the customer described. It actually felt somewhat like an abrupt engine misfire, something like you would feel in a manual-transmission car, or a misfire when the torque-converter clutch was applied.

It seemed to happen only at moderate to heavy acceleration between 15 and 40 mph and seemed to be a very brief binding sensation when it happened. Upon returning to the shop the first thing I noticed were the two new tires on the rear of the vehicle of a different brand name from those on the front, and I thought, “Hey, I got this one.” I grabbed the trusty tire stagger gauge and measured all four tires. I was shocked to find that they were all almost exactly the same circumference, even closer than most matching tires that have some miles on them.

Next step was to check for trouble codes. Our scan tool will retrieve codes from all modules in one step; the vehicle had no stored codes in the PCM, ABS or 4×4 module. At this point I set up the scan tool to look at the front and rear shaft sensors and the clutch duty cycle and went for another drive. Monitoring the clutch PWM showed that it was definitely the electromagnetic clutch that was causing the issue. The PWM percentage was not steady, randomly dropping out or coming on at the times you would feel the bind-up.

Looking at the speed sensors on the scan tool, they were a mirror image of each other, which I thought was odd with the transfer case acting as it was, so I printed a wire diagram and grabbed the wires to hook up the scope to the speed-sensor signal wires. At this point I was convinced that it was a speed-sensor issue and that the scan tool was just not fast enough to see the problem. I got the scope set up and went for another drive. As I watched the scope pattern while the problem was occurring I was amazed again; there was a clean signal with no dropouts (Figure 1). How could this be? I was still fixated on a speed-sensor problem.

When I got back to the shop and got on to the PC to look up service bulletins, on ALLDATA I found TSB 05-21-4, “SHUDDER IN 2ND AND 3RD GEAR ON ACCELERATION – 4X4 VEHICLES WITHOUT ADVANCETRAC”:

Ford: 2002-2003 Explorer

Issue: Some 2002-2003 Explorer 4×4 vehicles without AdvanceTrac (Interactive Vehicle Dynamics – IVD) equipped with an automatic transmission may exhibit a shudder in 2nd and 3rd gear on acceleration. This condition may be more pronounced when the vehicle is under load.

Action: Replace the 4×4 control module following the procedure in Workshop Manual Section 308-07A. Refer to the Part Application Table for the correct part number to install.

The bulletin fit the complaint as to when the problem occurred, but I did not feel it to be a “shudder,” so I moved on from there. Not having a definite path to follow I did a voltage-drop test on the ground side of the system. The worst ground I could find was the 4×4-module ground in the passenger-side kick panel at 47mv. I cleaned all the body grounds and got it down to 23mv with no change in operation.

I decided to pull the trigger and bought a new module, got it installed and drove the vehicle in the same manner as when I got the problem to occur. I had made several hard accelerations from a stop and could not duplicate the problem again, and the customer concern was fixed!

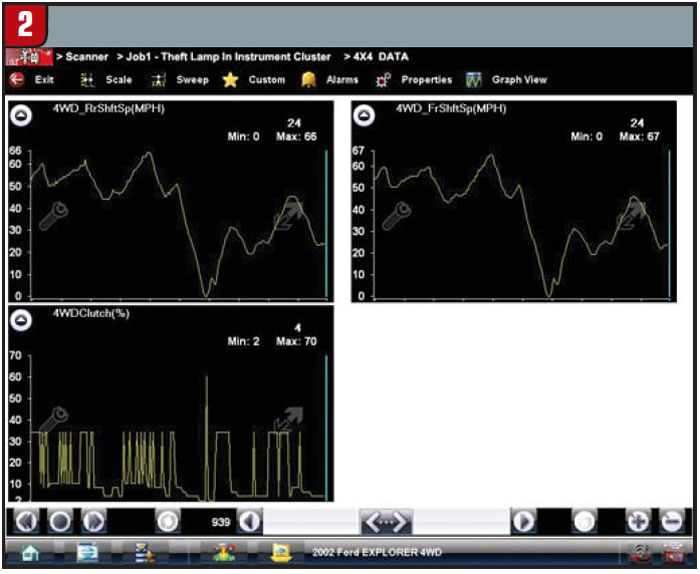

But as I was driving back to the shop I felt another issue, which felt more like a shuddering sensation, more so at just light acceleration, so I set up the graphs on the scan tool again and this is what I saw (Figure 2).

Did the new module cause this issue, or did I just not feel it before? So I plugged in the original module, and the first complaint was back but I still could feel this other issue.

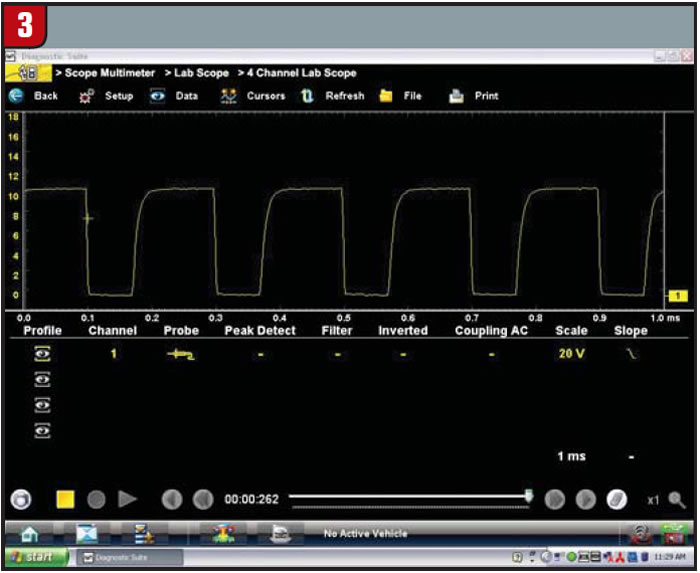

At this point I had already checked the speed sensors and scan-tool readings. The wiring diagram I was using showed a wire from the PCM to the 4×4 module that was not really defined as to what it was. I figured it was the input from the throttle-position sensor (TPS), but when I hooked up a voltmeter to the wire at the 4×4 module it did not look like a typical TPS reading you would see. Then I found this in the Description and Operation: “The PCM converts the TPS signal to a pulse width modulated signal, and sends it to the 4×4 electronic module to control and adjust the transfer case clutch duty cycle.” That made a little more sense, and again I set up the scope to look at this signal.

Figure 3 shows the duty cycle at a steady throttle, and Figure 4 shows a split second when the duty cycle dropped to what you would see at idle. This is what was causing the erratic 4×4-clutch PWM readings in Figure 2 and causing the shuddering sensation.

Installing a new TPS took care of this issue and it was smooth sailing for this problematic Ford Explorer.

Chris Adams is the lead diagnostician for Certified Transmission in the Omaha, Neb., area. He has been with the company for more than 25 years.