Campaigns and recalls have been a part of the landscape almost as long as the automotive industry itself. Some of the campaigns or recalls have been made public while others never made it to the radar screen.

Such is the case of a National Highway Traffic Safety Administration (NHTSA) campaign recall (#14V315000). The recall involves certain production months of the 2012 Chevy Sonic, equipped with a 1.8L engine and a 6T30 (RPO LUW). The range of months is from March to June, although Murphyʼs Law could make it apply to others.

The problem involves a potential fracture of the turbine shaft. If the turbine shaft breaks, the vehicle will quit moving of course. GM currently is recalling the affected vehicles to replace the turbine shaft, whether broken or not. Any vehicle that falls through the cracks could show up at a local repair shop. If a 2012 Sonic does show up and requires a major repair, it would be prudent to replace the turbine shaft unless it was replaced previously by GM. The 6T30 turbine shaft part number is 24231696 (Figure 1).

The 6T30 is part of the group of 6-speed front-wheel-drive transmissions developed by GM and Ford and is used in a variety of vehicles – domestic and foreign – beginning in 2007. The FWD models do have variations including the 6T30, 6T40/45, 6T50 and 6F35. As cores become more plentiful, parts identification will become more important. The 6T30 is a lighter duty version than the others.

Even something as simple as a turbine shaft could create problems if interchanged incorrectly. Unlike the 6T70/6F50 that has the turbine shaft made to the 3-5/rev 4-5-6 clutch drum, the 6T30/6T40 shaft merely splines to the drum. The shaft is held in place by a small snap ring, which is a real treat to remove. The 6T40 turbine shaft part number is 24235179.

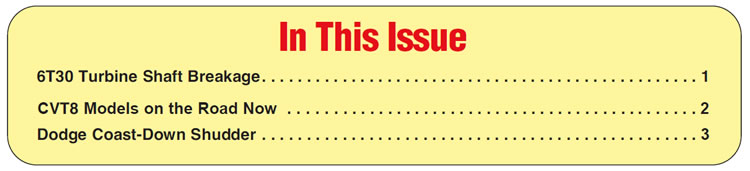

There is little likelihood of mixing up a 6T30 and 6T40 turbine shaft due to the spline counts, bushing diameter and length (Figure 2). Overall appearance is the same, however, so the question remains what is the deficiency with the 6T30 turbine shaft and is there the same potential with the 6T40 or 6F35 shafts? So far there does not seem to be a problem with those models.

The difference between the 6T40 and 6F35 is more subtle. All three spline counts and bushing diameters are the same. The length of the two shafts is where the difference is (Figure 3).

The 6F35 is the longer of the two. Refer to the chart for all three shaft dimensions (Figure 4).

Just because a component is good today, doesnʼt mean that it will be good tomorrow. Refer to the tech services for all TSBs, recalls or campaigns and avoid surprises.

Special thanks to Matt at Matlin’s Transmission in Aurora, Ohio for providing the basis of this article.

CVTs (continuously variable transmissions) have steadily been worming their way into the automotive industry for some time now. Ignoring them is no longer an option, especially for anyone that wants to remain in the forefront of transmission repair.

Although there have been a variety of manufacturers and models of CVTs, such as the Saturn VT25, ZF CFT30 (Ford), VW 01J, etc., the main player in this market has, of course, been Japan-based Jatco, whose CVT offering outpaces everyone else by a ton.

Basically, all CVTs operate the same, although there have been variations. Some CVTs would use a drive plate while others use a torque converter. Pump configurations could be gear, vane or piston types and controls and electronics have also changed over the years. CVTs also require their own fluid types, which must be used.

Jatco started to spit out CVTs internationally in 1997 to equip compacts with light-duty engines. Two of the initial applications were the RE0F21A and RE0F06A. As time went on, Jatco released more models to accommodate larger vehicles and higher output engines. In 2002, the RE0F08A (JF009E) was launched to start phasing out the F06A and to address trucks with bigger engines. The RE0F09A (JF010E) also hit the streets in 2002. This was another milestone for Jatco. The RE0F09A started to be used domestically in 2003.

Another light-duty variation was released in 2004 overseas and 2006 in the U.S., which was the RE0F10A (JF011E). Aside from overall capacity, the main difference between the F09A and F10A was the pump. The F09A pump is direct drive and the F10A pump is a chain-driven remote design like the 6T70.

A noticeable change occurred in 2009 when Jatco designed a different type of CVT, one with an auxiliary gearbox, or so it is called. The CVT7 (JF015E) basically is a two-step CVT that has a low and high gear in conjunction with the regular variator (pulley) ratios.

The auxiliary gearbox is little more than a compound planetary instead of a simple planet, along with an extra clutch pack to provide two forward speeds instead of one.

The most recent addition to the Jatco CVT lineup is the CVT8. Currently there are three models that are included in the design, JF016E, JF017E, and JF018E. The 016E is for smaller engines like a 2.5L whereas the 017E is for larger engines like the 3.5L. The 018E is actually a hybrid that uses an electric motor and start clutch instead of a torque converter. All three models use bits and pieces of previous CVT models. One way to identify the CVT8 is by the pan gasket (Figure 5). The gasket is the same as the Nissan RE0F10A pan gasket.

One improvement that the CVT8 has over other CVTs is the torque converter. The converter is redesigned and can apply, almost, from a stand still due to computer strategy. The CVT8 also requires an improved low viscosity fluid. Computer strategy on the JF018E would be substantially different.

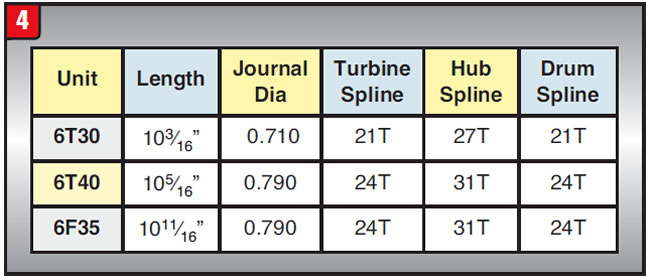

A noticeable deviation of the CVT8 beyond other CVTs is the drive component. Jatco decided to use a drive chain on the CVT8 (Figure 6a & Figure 6b). The chain, which is produced by LUK, is similar to the chains on the 01J or CFT30. To separate the chain and variators (pulleys) can be a chore.

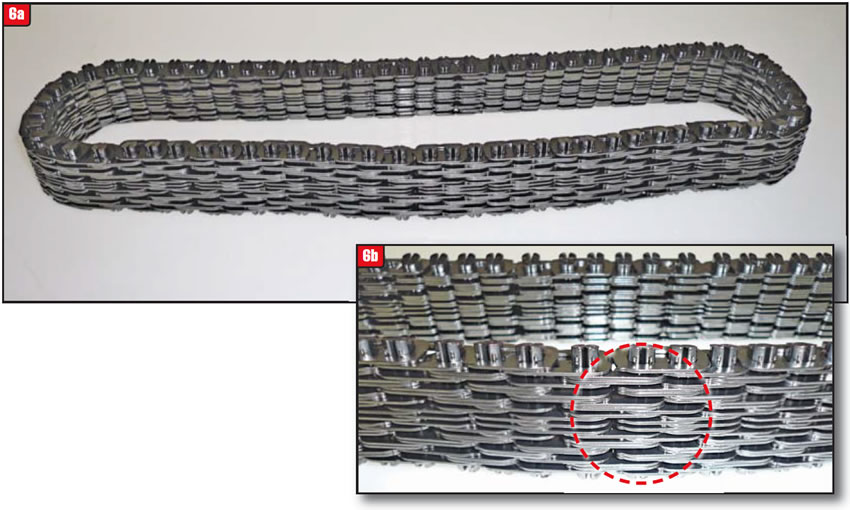

The CVT8 uses two plastic chain guides that need to be removed first (Figure 7). Split the sides of the guides in order to remove them, which will then provide enough slack in the chain to separate the components.

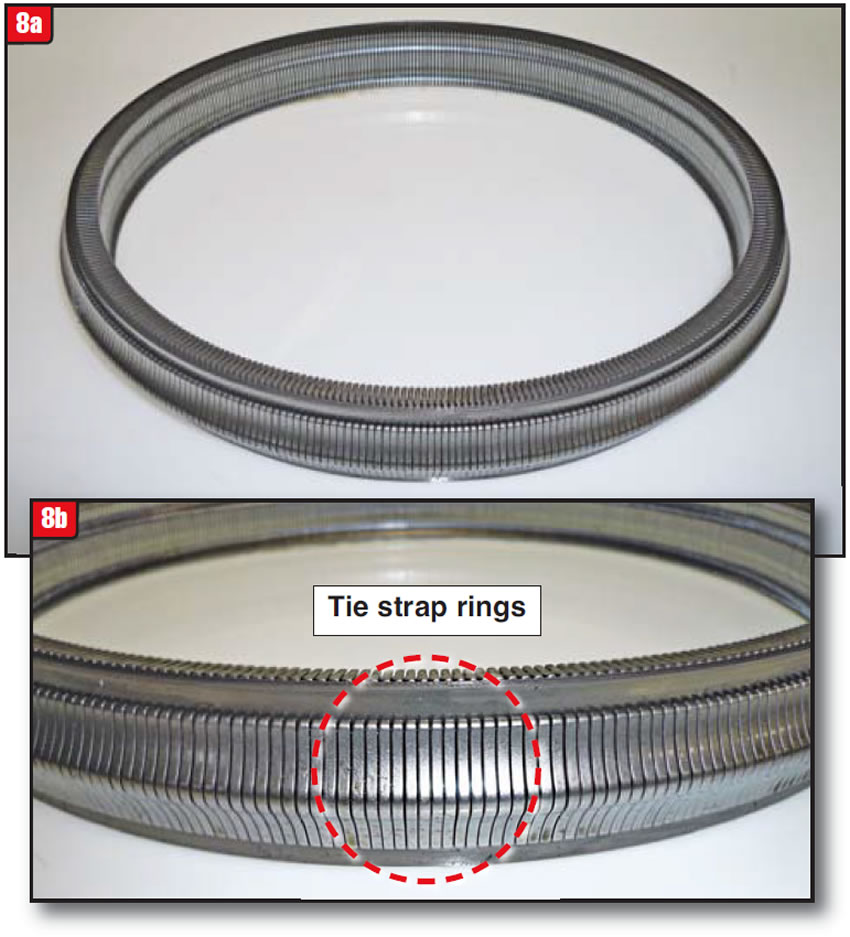

Up to that date, the preferred Jatco drive component was a push belt (Figure 8a & 8b). Always use caution when handling a push belt, because if the steel rings slide off, the belt will become 400 little pieces of metal. Put plastic wire ties around the belt so that doesnʼt happen.

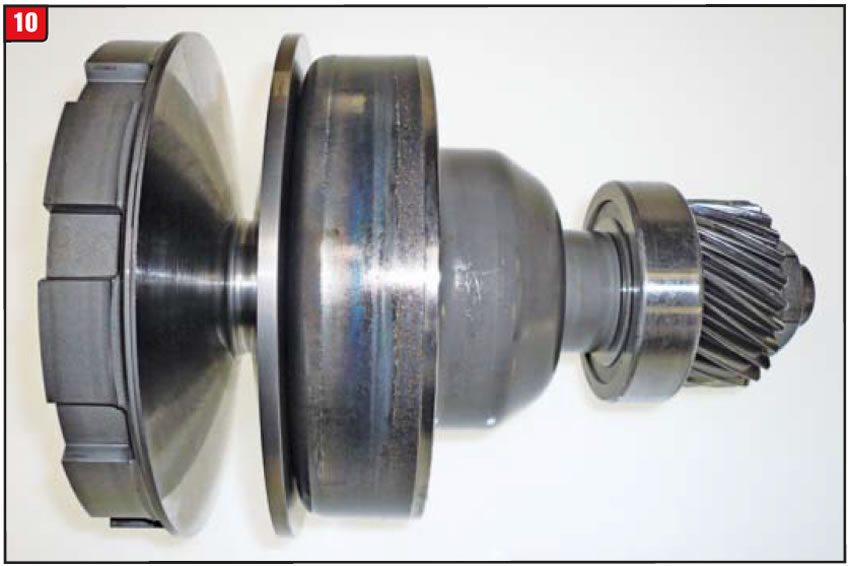

To increase the ratio spread beyond what previous models were (0.6 to 0.7), the variator axis was changed on the CVT8 as well as the chain angle of the sheaves. The drive variator (Figure 9) and driven variator (Figure 10) do, however, look like other CVTs. The variators can be disassembled by removing the nuts, bearings, and gear. Using a torch, heat the seal retainer of the drive variator at the center and bang the shaft end downward on something solid so that the weight of the moveable side pushes off the retainer. Repeat the process for the driven variator, but be careful, the spring will pop the retainer once heated and itʼs strong.

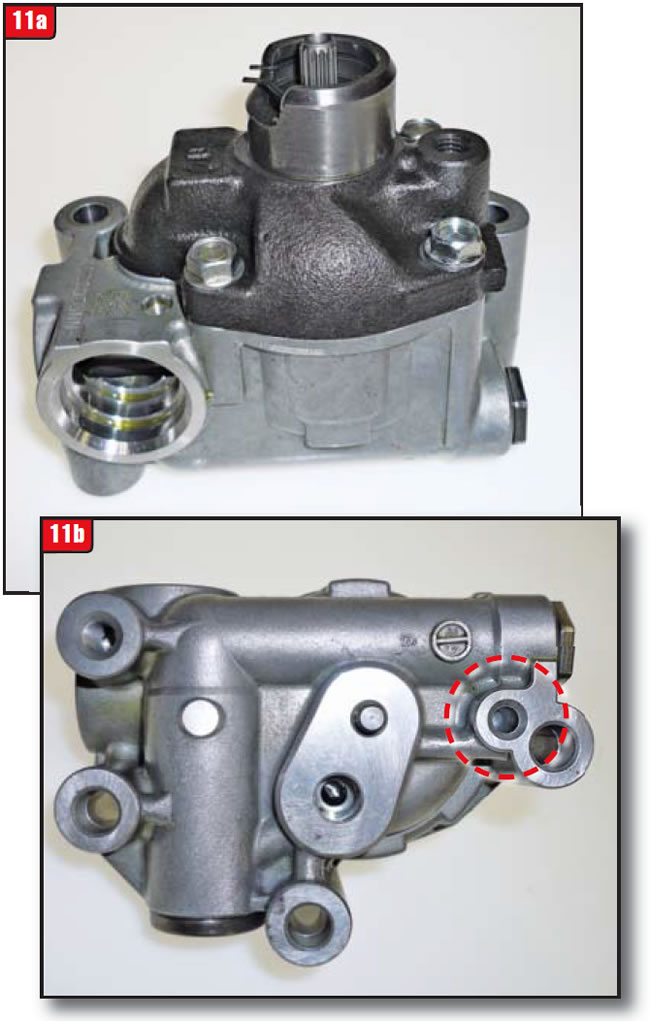

The pump chosen for the CVT8 is the remote design (Figure 11a), just like the RE0F010A design. More transmission applications are going to this due to economy and performance. The CVT8 is almost identical to the F10A, except for one oil hole in the body (Figure 11b). Do not mix them up.

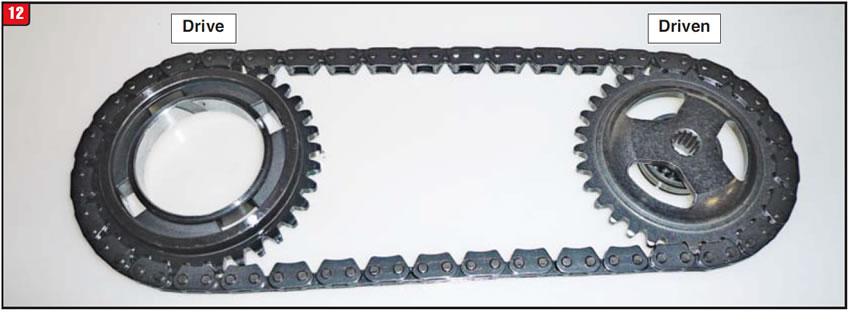

The remote pump design also uses a drive and driven sprocket along with a drive chain (Figure 12). The drive sprocket has a bushing for support, while the driven sprocket uses a bearing. Replace the components if the chain has excessive looseness. The pump is a vane type.

Do not mix them up. The remote pump design also uses a drive and driven sprocket along with a drive chain (Figure 12). The drive sprocket has a bushing for support, while the driven sprocket uses a bearing. Replace the components if the chain has excessive looseness. The pump is a vane type.

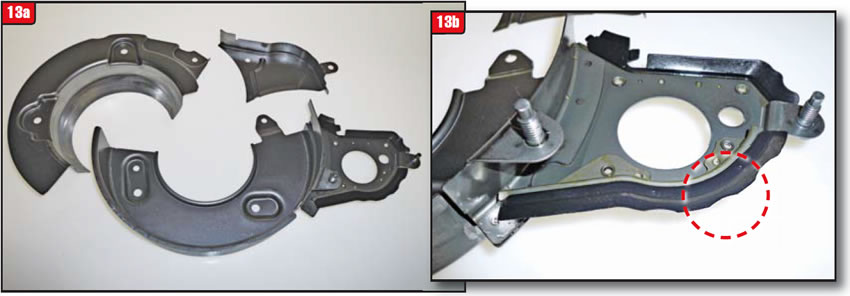

Another key concern of Jatco was to reduce friction and drag which is why new low viscosity fluid was developed. Cutting down oil agitation is part of that. The CVT8 also uses a fair amount of shrouds to minimize splash (Figure 13a). They even used rubber around the edge of the shroud to help control the splash (Figure 13b).

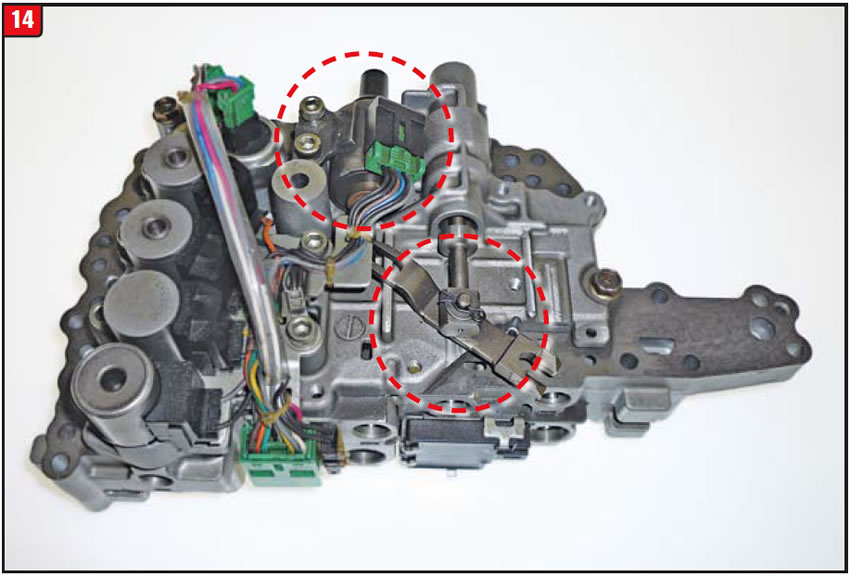

Electrical controls are always changing and the CVT8 is no different. Previous model CVTs used a ratio control motor and lever to work in conjunction with the drive variator position, to determine overall ratio (Figure 14).

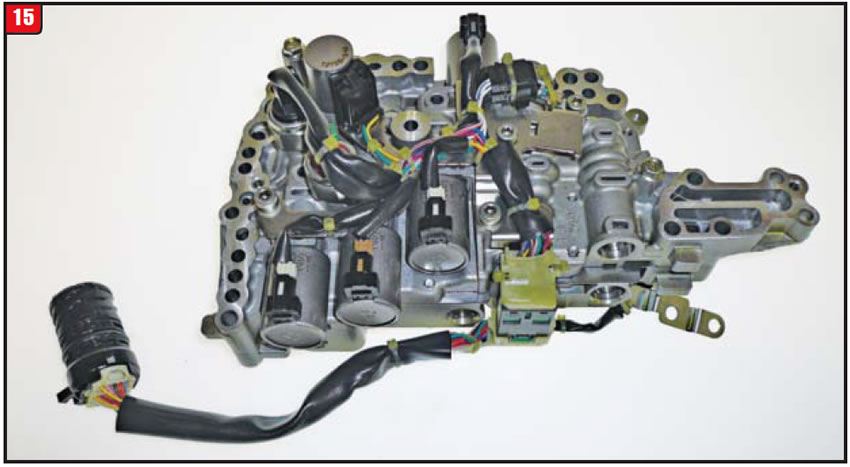

There are also the required amount of solenoids and pressure switches. The CVT8 valve body merely uses solenoids and pressure switches, no ratio control motor (Figure 15). Jatco was also able to reduce the amount of valves on the CVT8 from previous models. Other strategies are used to determine the ratio on the CVT8.

In addition to the sump filter that other CVTs use, the CVT8 also has an extra cartridge filter for added filtration, similar to the RE0F10A (Figure 16). When doing a service, always replace that filter along with the fluid and sump filter.

How many more models of CVTs will pop up before itʼs over is anyoneʼs guess. “The hits just keep on comin.”

A customer was experiencing a vibration while coming to a stop in a 2009 Dodge Challenger. The vehicle was equipped with a 5.7L engine and a NAGI (722.6) transmission and only had 72,000 miles on it.

The vehicle was taken for a road test and worked fairly well. All upshifts and downshifts were positive and the lock-up torque converter applied normally. At times, however, while coming to a stop, the transmission would shudder just like the converter clutch was malfunctioning. A scanner was hooked up to see how the TC clutch was being commanded. Everything appeared to be in order.

To further complicate things, the condition was erratic, meaning at times there was no shudder or vibration. Beyond that, any time that the shifter was placed into manual mode (auto stick) the unit worked well.

Just for kicks and giggles, the fluid was changed and an additive was used to see if it had any effect on the coast-down shudder. It didnʼt. The question then was to rule out other possibilities or yank the transmission.

After a little nosing around, information turned up that Dodge was having some issues with motor mounts. A bad or weak motor or transmission mount can certainly magnify torsional vibration from a variety of sources (plug misfires, fuel issues, lock-up shudder, etc.). The engine and transmission mounts did not appear to be broken, but thatʼs not the only consideration.

As a gamble, both engine mounts were replaced and, lo and behold, the vehicle worked great –upshifts, downshifts, lock-up (under power, cruise, or coast), everything was smooth.

Although computer strategy cycles the converter clutch in a certain manner on coast down, any torsional vibration must be dampened properly by the mount system. For years, a greater emphasis has been placed upon mounts. Smaller engines required a softer rubber to allow more movement, while hydraulic mounts were developed to streamline dampening capabilities. Unfortunately, hydraulic mounts would leak causing an increase in NVH (noise, vibration, harshness).

A few years ago, a more tunable mount was released called ACM (Active Control Engine Mount) that works with vacuum to adjust the mount stiffness. The PCM controls a vacuum switch valve that sends the vacuum signal to the mount.

More recently, electronics have entered the mount game through the use of MR fluids (Magneto Rheological Fluid). Also called ER fluid (Electro Rheological Fluid) it contains metal particles that solidify with an electrical current. The PCM can control the stiffness directly to fine-tune absorption.

The original mount used by Dodge was part #4578046AE and was listed for all included models. There are now two part numbers available: For 2005-up non-police vehicles, use part #4578046AF (Figure 17),

but for police applications, another mount (part #5180406AE) was developed and should be replaced in a set (Figure 18). Always check for the correct mount number based upon application just to be sure. The mounts are not cheap, either, so be prepared.

Always make sure to eliminate external possibilities before removing the transmission or it may end up being done for free.

December 2014 Issue

Volume 31, No. 12

- 6T30 Turbine Shaft Breakage – Or Not

- CVT8 Models on the Road Now

- Dodge Coast-Down Shudder