R&R Tech

- Author: Troy Hopp

- Subject Matter: 4R75E

- Issues: Debris, short

About two months ago a customer brought in his 2006 Ford E350 Econoline van equipped with a 5.4L engine and a 4R75E transmission for an evaluation. His concern was that the check-engine light was on and the transmission seemed to shift hard at times. We always begin our evaluation with a battery and charging system test with a Midtronics electrical system analyzer, and we scan all modules for codes using a Snap-on Verus Pro if we are not using an OE scan tool. After a quick visual inspection of the vehicle and checking the engine oil level, we will proceed with the road-test.

After scanning the PCM, I pulled two codes that were stored: P0740 (Torque Converter Clutch Fault) and P0743 (Torque Converter Clutch System Electrical Fault). The fluid level was correct, but it was dark red in color with a slightly varnished smell. My next step was to clear the codes and try to duplicate the customer’s concern. After driving the van about five minutes, the torque-converter clutch started to shudder and I could see on the scan tool that the torque-converter clutch was slipping. P0740 and P0743 both reset and the transmission began to shift hard because it went into limp mode. At this point I was fairly confident that the problem was a slipping torque-converter clutch, but to be absolutely sure I obtained the customer’s permission to perform a visual pan inspection. A quick removal of the pan revealed a large amount of metal and clutch debris confirming an internal transmission failure.

After explaining the course of repair to the customer and obtaining repair authorization, we replaced the defective transmission with our remanufactured unit. All of our transmission installations include hot-flushing the oil coolers to ensure complete debris removal from the entire system. We also reprogram the powertrain and/or transmission control modules to the latest calibration for optimal operation. While the transmission is removed we also thoroughly inspect the flex plate, rear main seal, engine mounts, transmission mounts, U-joints and/or CV joints to ensure everything is in good working order and replace them if needed, then complete the installation of our remanufactured transmission.

With the installation completed and all of the updates performed, it was time for a final road-test to make sure the customer’s concerns were all alleviated. The 25-minute road test verified that the torque converter clutch no longer shuddered or slipped and the transmission shifted and operated perfectly. However, after getting the van back to the shop, a quick scan of the codes revealed that the P0740 code had not returned, but the P0743 code had. It was now apparent that the van had two different issues at play.

I cleared the code once again and went for another road test, but this time I had another technician with me to monitor the scan tool for PCM commands while I drove the vehicle. For the first several minutes everything was working just fine, but the converter clutch seemed to apply earlier than it had on the previous road-test, so I asked the tech if the TCC was commanded on. He stated that it was not, so it seemed we were getting our scope narrowed down to an electrical issue. A quick scan for codes showed that the P0743 had returned, so then we returned to the shop.

At this point I was comfortable to assume that the P0743 code was most likely caused by an external wiring problem, or possibly by the PCM itself. Since the torque converter clutch was apparently being commanded on and off by the PCM properly, the PCM was not my first suspect. I felt it was safe to assume the PCM was OK, based (in part) on the fact that we rarely have to replace a PCM in a Ford application, so I first decided to direct my attention to the wiring harness and connectors.

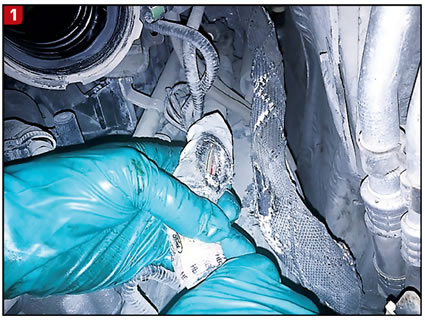

After a close visual inspection of the connectors at the transmission and at the PCM, I verified that they were clean and the terminals were tight and making good contact. When I back-probed the TCC solenoid control wire at the PCM with KOEO, I had full battery voltage and the circuit seemed to ohm out fine, but something had to be amiss that these tests did not reveal. I decided it was time to inspect the wiring harness, but of course no problems were found where the harness was easily accessible. Removal of the engine cover (dog house) was required for a complete inspection of the wiring harness.

Once the engine cover was removed it was revealed that the harness was lying against the EGR tube and had melted through the harness conduit and into the insulation on the torque-converter clutch solenoid wire, thus causing it to ground out through the EGR tube and setting the P0743 code (Figure 1). I cannot completely explain the intermittent nature of this issue or why it would just act up when it was hot, but I can theorize that the EGR tube only made enough contact with the wire when there was some heat expansion of the pipe, or just from some movement while driving.

I repaired the shorted wire, replaced the conduit where it was melted and properly secured the harness away from the EGR tube. Now it was time to reinstall the engine cover and take the van out for another final road test. I drove the van for 30 minutes and the transmission shifted and operated OK, the check engine light stayed off, and no codes were reset. Now both of the codes were repaired, and the customer picked up his van and was on his way.