Torque Converter Tech Tips

- Author: Ed Lee

A 2001 Dodge Ram 2500 4×4, with a Cummins diesel engine and a 618 transmission, was brought to a transmission shop with a complaint of TCC shudder. Three to four months prior to coming to the shop, the customer noticed a change in the TCC-apply feel. He said that the TCC apply had suddenly become more aggressive or abrupt. The condition had worsened over the course of three to four months, until the start of the shudder issue.

The customer was retired and used the vehicle to tow his camping trailer around the country. He had several performance enhancements added to the engine, including an aftermarket turbo. Since the engine performance was enhanced for better towing capacity, he did not complain about the firmer TCC apply until it developed into a shudder.

The transmission in the vehicle had been rebuilt at 93,000 miles, in January 2007. At that time, a rebuilt torque converter was also installed. The vehicle returned to the transmission shop in May 2008 because the torque-converter bolts had come loose. During that repair, the flywheel was replaced, and the torque converter was rebuilt and upgraded to include a billet cover. The TCC friction material was replaced, but the original piston and damper assembly had been reused.

Now the truck had returned to the shop with the shudder complaint. All the usual preliminary checks were performed on the vehicle, including checking the line pressure and cooler flow. Since the results of all the external checks were within the proper parameters, the problem was narrowed down to the converter.

When the converter was cut apart, the TCC friction material was found to be degraded. The surface had been hot because of the shudder issue, but it also had the appearance of extreme use. The reason for the friction-material failure was not immediately obvious. The turbine-hub seal and the TCC-piston bore were both in good condition. The reaction surface on the cover was also good.

Other than the lining material, the only things that did not look good were the springs in the damper assembly. It was obvious that the damper springs were continually being bottomed out. The technician reasoned that the combination of the enhanced performance of the engine and the increased loads due to towing the camping trailer exceeded the capacity of the damper assembly.

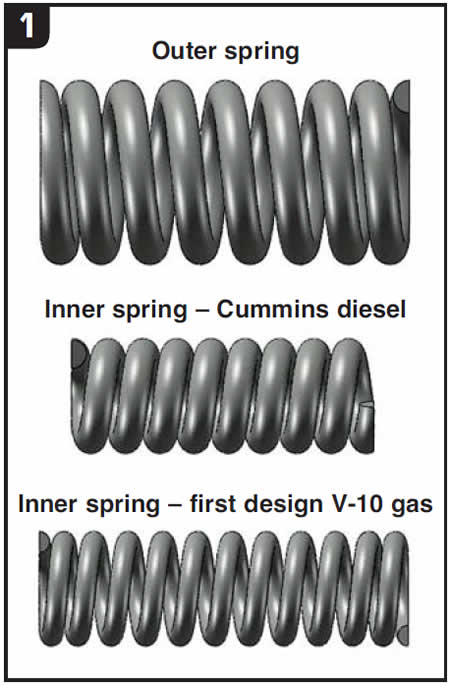

The torque-converter rebuilder started searching for a replacement damper assembly. He soon found that there were two distinctly different types. One assembly style had an inner spring that was the same length as the outer spring, and the other had an inner spring that was somewhat shorter than the outer spring. His original damper assembly was the type with the shorter inner springs. He later learned that the damper with the shorter inner springs was a two-stage apply, designed for the Cummins diesel engine. The damper with the same-length inner and outer springs was a one-stage apply, the first design used for V-10 gas engines (Figure 1).

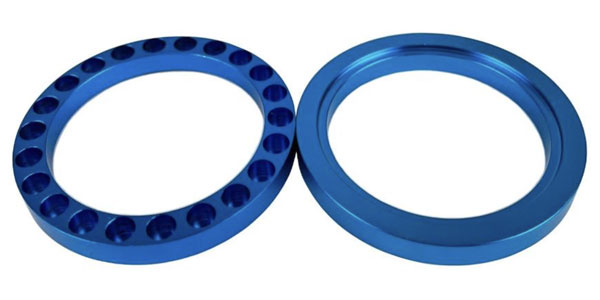

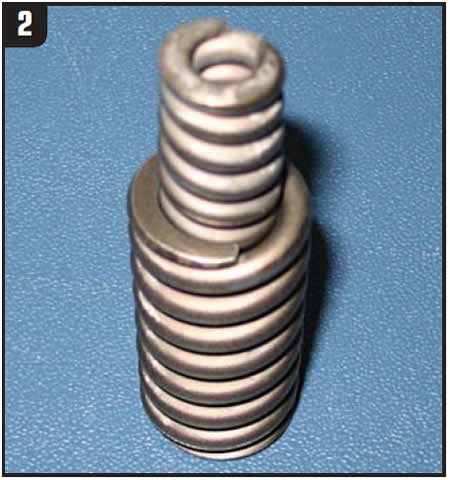

Converters used with later-model V-10 gas engines had the same shorter inner springs as those used with the Cummins diesel engines but had the inner springs pressed into the outer springs. This was done for ease of installation and to make balancing easier. Closer examination of the springs showed that the center coil of the outer spring had a slightly smaller diameter than the rest of the coils. The smaller-diameter center coil of the outer spring holds the inner spring in position after they are pressed in. The inner springs all have a consistent outside diameter and will fit easily into the outer springs until they reach the center (Figure 2).

Because of the enhanced engine performance, the technician decided to replace his two-stage-apply damper with the one-stage-apply damper because it had a slightly higher initial apply capacity.

This proved to be a good decision, because when the damper was replaced and the torque converter was reinstalled in the vehicle, the TCC apply returned to normal.

For this customer, replacing the correct-application damper with a damper meant for another application was the best decision. This may not be the case with other customers; the dampers should be identified correctly and used in the proper applications.