November 2008 Issue

Issue Summary:

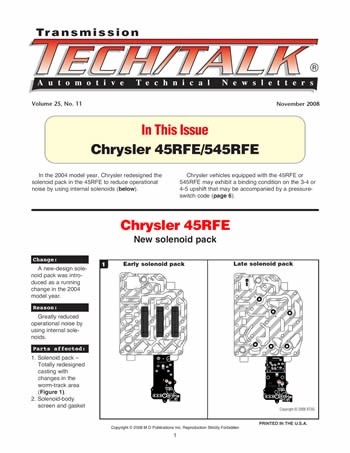

In the 2004 model year, Chrysler redesigned the solenoid pack in the 45RFE to reduce operational noise by using internal solenoids.

Chrysler vehicles equipped with the 45RFE or 545RFE may exhibit a binding condition on the 3-4 or 4-5 upshift that may be accompanied by a pressure-switch code.

Making a Go of It in the Toughest of Times

What about these tough times? Are they tough for everyone? Apparently not; it depends on what business you happen to be in and what you make of the current economic conditions.

Centerline Issues: TCC Frictions Bonded Off Center

For several decades the importance of the torque-converter centerline has been hammered home by Don Randolph of DACCO Inc. Don’s sentiments on this subject have been echoed by the torque-converter original-equipment manufacturers (OEMs). In fact, every OEM torque-converter print starts with a true axial centerline, which serves as the reference point for all axial measurements.

Solenoid Control in the TF60-SN (09G/09K/09M)

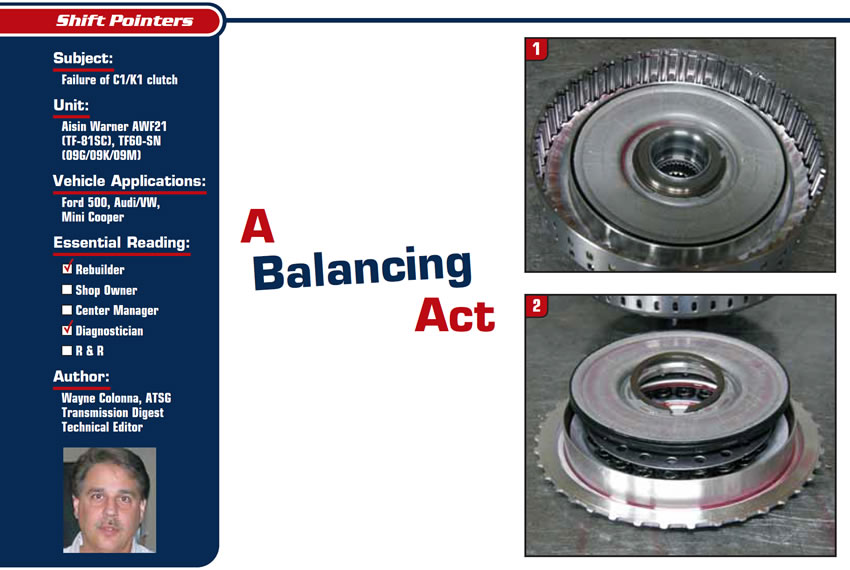

Starting with a few four-speed automatic transmissions, increasing with the five-speeds and more so with units having six or more speeds, it is interesting to see the use of counterbalance pistons in clutch drums that drive the planetary system. Since drive-style clutches are rotational, there is a tendency for centrifugal force to creep the clutch on when it is not in use, which could cause premature damage to the frictions.

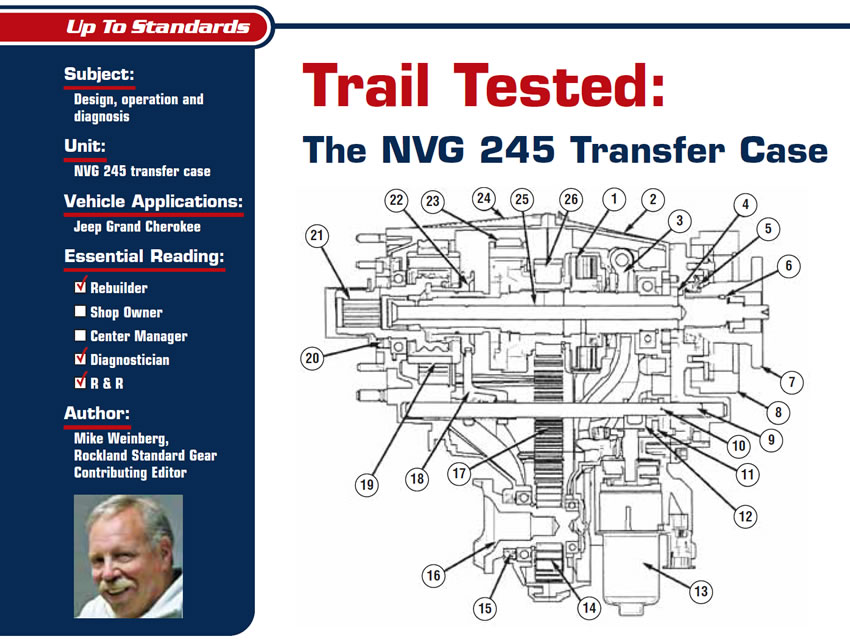

Trail Tested: The NVG 245 Transfer Case

Jeep is the originator of four-wheel-drive vehicles, and even though the brand has been owned by numerous corporations over the years, it is still the centerpiece of four-wheel activity. The top-of-the-line Jeep model is the Grand Cherokee – or WK series, in Jeep speak.

Chrysler RWD Valve-Body-Linkage Pivot Wear

The basic design of the internal shift linkage of Chrysler/Dodge rear-wheel-drive transmissions has not changed since 1967 (Figure 1). As movement, vibration and wear take their toll over time, looseness of the internal linkage becomes a big problem. When there is excess movement in the manual lever, the manual valve is not held precisely in position, resulting in fluid leakage, cross leaks and unit failure.

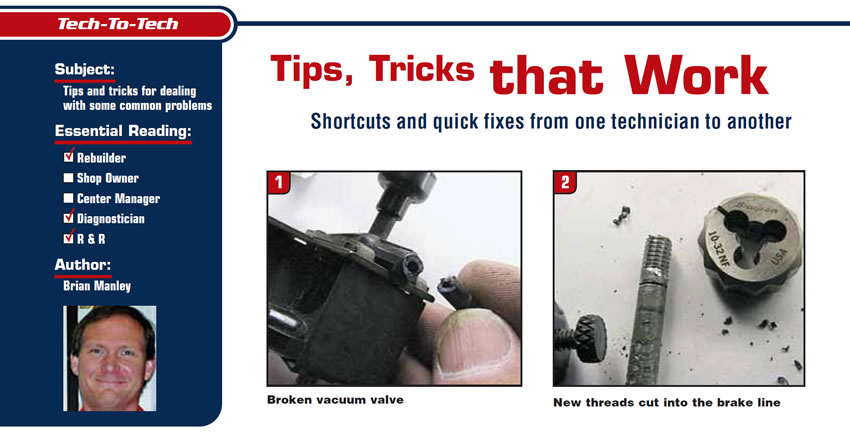

Tips, Tricks that Work

Let’s face it: Sometimes bad things happen to good technicians. Have you ever found yourself in the situation where you are trying to fix a problem, only to create a new one? I have popped the hood to check for a vacuum leak and, in the process, created a vacuum leak by snapping a plastic port off. In this month’s column, I will share a handful of cool tricks and tips that I’ve picked up over the years from co-workers, classes and forums.

A Balancing Act

If you just read the “Technically Speaking” article in this edition of Transmission Digest you might recall that we spoke a little about how balance pistons are being used in rotational clutch drums, and their purposes. This article covers one of the problems we have seen with the C1/K1 clutch (Figure 1) as it relates to the AWF21 (Aisin TF-81SC, used in the Ford 500) and the TF60-SN (09G/K/M, used in Mini Cooper, Audi/VW) transmissions.