More Details

Producing a quality rebuilt torque converter is a major accomplishment. You have to perform many rebuild procedures correctly to end up with a quality finished product. Simply knowing the difference between the right and wrong way of doing a rebuild procedure doesn’t always guarantee success. It’s important to pay attention to the many details of the rebuild, and the proper use of shims is one such detail.

A Dozen Rules for Prospering in a Recession

Welcome to “Recession 2008.” It’s been a long time coming, but now it’s here. Should we be happy or sad about it? I guess that depends on a number of factors, so let’s take a look at them.

First, some definitions:

Recession – When your neighbor loses his job

Depression – When you lose yours

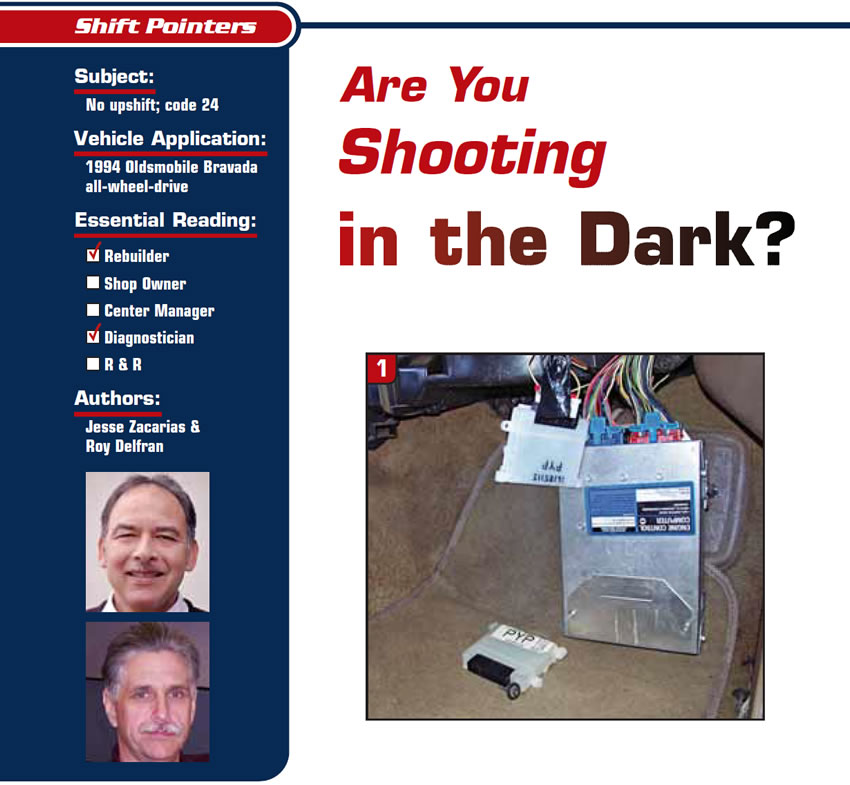

Are You Shooting in the Dark?

Knowing how an electronic component is supposed to work is very important when you are troubleshooting it for a problem. It can make the difference between replacing parts because you know they are bad and replacing them because you think they are bad. Half the battle in troubleshooting a device is knowing how it’s supposed to work, what to expect from it, what is normal and what is not.

Getting to the ‘Core’ of the Problem

Cores and core charges have been part of our industry since the beginning. What is a core? There can be many definitions, but for the purpose of this discussion we will label it as a used or worn/damaged component or assembly being replaced by a remanufactured component or assembly that is identical to the one being replaced.

A Disappointing Reality

One recent week, Luis was having a problem with an 01M in a 2002 VW Jetta (see Figure 1). It had a slight bind-up on the 3-4 shift. It didn’t make a harsh shift; it was more like a dragging shift that lasted for about 1 second and then suddenly released when it finally went to fourth. Typically, what we see on the tech lines is more of a 3-4 shift flare rather than a dragging shift. This flared-shift complaint is usually due to either an incorrectly assembled K1 or B2 clutch pack or a leak in the K1 pre-fill pressure circuit causing the clutch to release too soon. However, a dragging shift also could be due to an incorrectly assembled K1 or B2 clutch, or a valve-body problem.

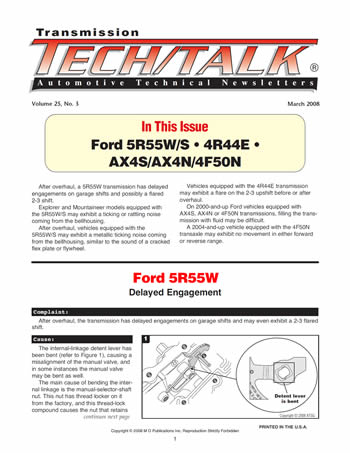

March 2008 Issue

Issue Summary:

After overhaul, a 5R55W transmission has delayed engagements on garage shifts and possibly a flared 2-3 shift.

Explorer and Mountaineer models equipped with the 5R55W/S may exhibit a ticking or rattling noise coming from the bellhousing.

After overhaul, vehicles equipped with the 5R55W/S may exhibit a metallic ticking noise coming from the bellhousing, similar to the sound of a cracked flex plate or flywheel.

Vehicles equipped with the 4R44E transmission may exhibit a flare on the 2-3 upshift before or after overhaul.

On 2000-and-up Ford vehicles equipped with AX4S, AX4N or 4F50N transmissions, filling the transmission with fluid may be difficult.

A 2004-and-up vehicle equipped with the 4F50N transaxle may exhibit no movement in either forward or reverse range.

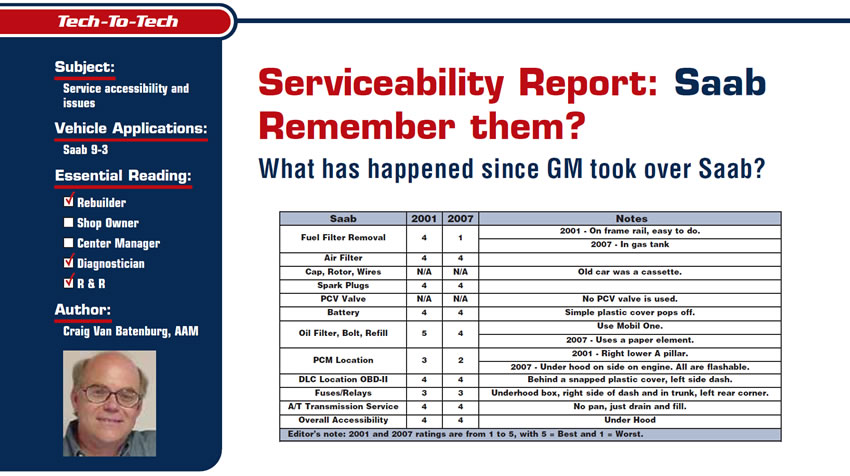

Serviceability Report: Saab

Remember them? What has happened since GM took over Saab?

So far, we have reviewed Japanese, Korean, English, German and domestic vehicles – vans, trucks and cars. Are the Swedish better at serviceability? Many of us remember the old Saab two-strokes, mixing the oil in the gas. Today’s commercials explain the Saab story with jets flying overhead. General Motors Corp. bought Saab in 1990, and sales haven’t been all that good since the new owner took over. I went on a mission to discover more about this somewhat-forgotten brand. What did I find out? I used the Saab 9-3 for my study.

Tips for Quality Rebuilding

Have you ever wondered why some rebuilders never seem to have a comeback? Their units are installed, test driven and delivered time after time without any problems. Their success is the result of a combination of things that any transmission rebuilder with motivation and good skills can do.