GM Transfer Cases: New Designs, Old Problems

New Venture Gear, a manufacturing arm of Chrysler Corp., was bought some years ago by Magna International, one of the world’s premier supplier of parts to automakers around the world. The division that produces the transfer cases has been renamed Magna Powertrain. GM introduced a new series of transfer cases in mid-2007, and these units are now coming into our shops for work. This will be the first in a series of articles regarding these transfer cases and going over identification, theory of operation, and overcoming some design defects and issues that are now showing up in the marketplace.

It’s Not in the Manual

A while back one of our members called the tech line about a 2002 Toyota Sequoia that required replacement of the valve body. After the valve body was installed the vehicle had no reverse, pulled forward in neutral but drove perfectly when the selector lever was in the overdrive position.

January 2013 Issue

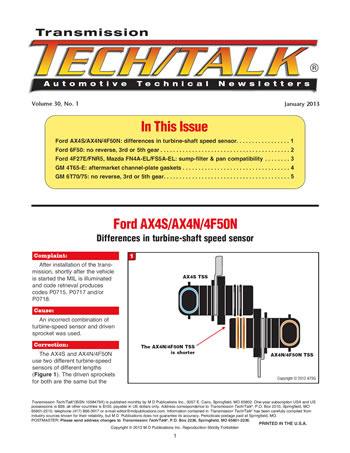

In This Issue

Ford AX4S/AX4N/4F50N: differences in turbine-shaft speed sensor

Ford 6F50: no reverse, 3rd or 5th gear

Ford 4F27E/FNR5, Mazda FN4A-EL/FS5A-EL: sump-filter & pan compatibility

GM 4T65-E: aftermarket channel-plate gaskets

GM 6T70/75: no reverse, 3rd or 5th gear

Chrysler’s ‘Christmas Tree Stump’ Code

Chrysler transmissions have been difficult to diagnose for technicians since the beginning of electronic shift solenoids.

They use a separate transmission-control computer that is sometimes hard to read.

GM Release-Bearing Installation

The design of the release fork on many GM applications can contribute to a common installation error.

I Hate Email

Here is a list of 10 best practices for handling email that I have developed and do my best to follow.

Continuity Conundrum

We spend a great deal of time helping installers with electronic-circuit codes for shift solenoids, PC-solenoid codes, input and output speed sensors, and pressure switches. Nearly all vehicles have issues with circuit codes. The focus of this article will be on Chrysler transmissions, as they seem to have more of these types of concerns than other vehicles.

Two- and three-pin harness connectors have been used for quite some time, and they have always been a primary source of circuit problems. The issues with them seem to be getting more prevalent since the vehicles that use them are aging. Loose pin fit and corrosion are the primary causes found with them, and cleaning with a heavy base (baking soda, for example) and a mild steel brush will usually dissolve the corrosion.

Don’t Blow It

The JF506E in VW, Land Rover and Jaguar applications experiences a condition of no upshift out of first gear when cold due to mechanical malfunctions of the 2/4-brake timing and duty solenoids (Figure 1). And there are times when this transmission may also experience a no-reverse condition due to a mechanical malfunction of the low-clutch timing solenoid (Figure 2). This information has been in our past seminars as well as in our bulletins, and since the cold season is upon us it’s good to keep this in mind.

Valve-Body Qualification

Although traditional visual indicators such as the wiggle, deflection, flashlight and visual bore-wear inspection are still useful, we’ll start this review with pressure and vacuum before finishing up with valve-body test stands.

Be Prepared!

“Be Prepared” – the Boy Scout motto. I grew up with it. It was great for teaching us how to think ahead, to hopefully be ready for anything that comes along. What came along in the fall of 2012 no one could fully prepare for: a hurricane followed days later by a Nor’easter that turned into a snow event that shattered the record snowfall for that date by about 4 inches.

The significance of all this is that for the first time in the northeastern United States there wasn’t enough preparation to be done that could have avoided so much of the devastation. Instead of hundreds or thousands being without the essential utilities like power and water the way we are used to seeing after a bad thunderstorm, this time it impacted millions and will continue to for quite some time.

Rebuilding 55-50, 09G, TF80 and TF81 Linear Solenoids

The linear solenoids on the Aisin valve bodies control line pressure, shift pressure, shift/engagement feel and lockup control. A linear solenoid that is sticking can cause all sorts of problems depending on the solenoid and the transmission type. The linear solenoids need to be rebuilt as much as the valve bodies do on these transmissions. The pintles stick and the outer shell (can or shell) can become distorted or loose.

Productivity and Profitability

Time management and planning are critical to getting the one or two extra jobs a week. Is the manager making good decisions? Is he working on jobs that will not be picked up this week when money jobs are sitting on the bench? Are parts being ordered as soon as the sale is made so that waiting on parts is not slowing production? Every production mistake delays cash collection.