July 2007 Issue

Issue Summary:

Before and after a rebuild, the transmission may experience premature failure of the reverse, direct or coast clutch.

The vehicle owner may complain of a delayed reverse and/or flare on the 3-4 shift and may feel bind-up in reverse and 4th. The unit may failsafe with a code for incorrect 4th-gear ratio.

After a rebuild, the converter clutch may not operate, possibly producing code P0741, “converter clutch slippage detected.”

BMW vehicles may exhibit a delay of two to 30 seconds from Park into Drive during the first cold start in the morning.

The malfunction indicator lamp is illuminated with code 55 or P0735 stored for “Gear Ratio Error in 5th Gear.”

There are no complaints of slipping or poor drivability.

Some vehicles may suddenly exhibit a bind-up on the 1-2 shift.

Myth Busters

In parts 1 and 2 we looked at the results of chassis-dyno testing conducted on torque-converter modifications by Sean Boyle’s students in the automatic-transmission course at Southern Illinois University. The testing was done on an MD-250 Mustang chassis dyno, and the test vehicle was a stock 2000 Dodge Durango RT equipped with a 5.9-liter gas engine and a 46RE transmission.

Déjà Vu All Over Again

When GM introduced the stamped-steel drum for the THM 200 transmission, it presented technicians with some new challenges. The 200 direct drums would crack where the inner liner (where the piston lives) was joined to the outer shell. The weld that holds the two members of the drum together is subject to pivotal flexing each time the clutch is applied. Over time, this flexing action will cause a crack at the weld.

Aggressive Street-Level Marketing

I’ve fielded way too many phone calls lately from shop owners who tell me that their wholesale and fleet business is off.

As Bob Cherrnay always said, “You don’t have to be an Indian to read signs.” The reasons should be obvious. The problem is that too many owners have had their heads in the sand for too long.

A Quick Fix for an Earlier Fix

Do you recall that feeling you get when you first figure out that the transmission on your bench has been worked on before? The signs could be obvious, like a painted case, but other times it’s not until you start tearing it down that you see clues that someone has been there before you. For me it is always a bit of a disappointment, because I know I have to watch carefully for changes that someone else made that could affect the transmission when I’m finished with it.

Coping with Capillary Action

Capillary action is defined as the movement of a liquid within the spaces of a porous material due to the forces of adhesion, cohesion and surface tension. A simple example would be dipping a paper towel into a glass of water and watching it climb up the towel. If the towel is long enough, eventually the force of gravity will be too great for the water to overcome.

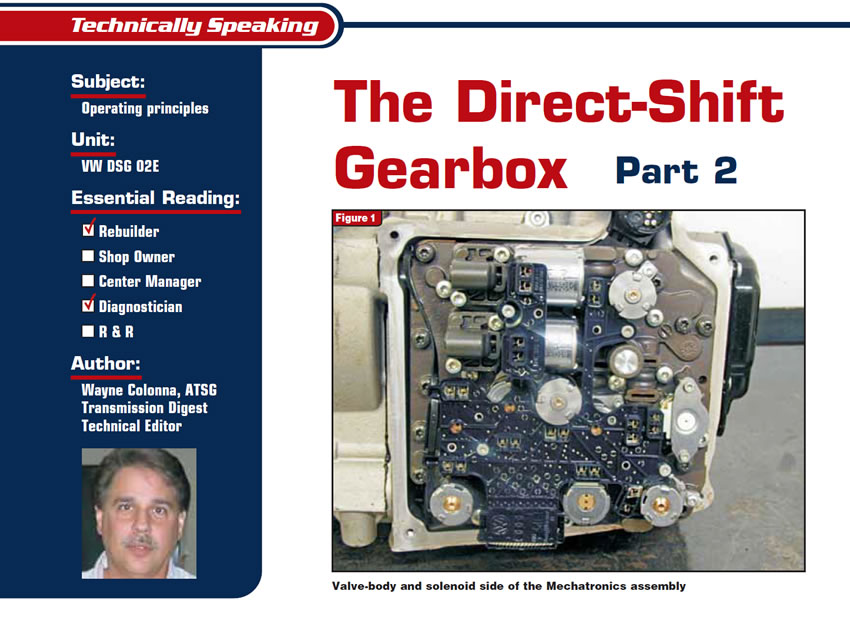

The Direct Shift Gearbox Part 2

Housed inside the six-speed direct-shift gearbox (DSG) is a Mechatronics assembly consisting of a control module, valve body and solenoids (see figures 1 and 2). It is the control center that shifts this manual gearbox automatically by turning on and off two separate clutch drums called the K1 and K2 clutches.

June 2007 Issue

Issue Summary:

In Allison 1000/2000 units, a sticking transmission-pressure-switch assembly can cause complaints of erratic shifting, a shift to the wrong gear and limp mode with the malfunction indicator lamp illuminated.

The forward-clutch drum in a 4R75E is susceptible to cracking in the area of the snap-ring groove, lead-ing to excessive slip in all forward ranges.

It’s Your Money – Protect It!

When I first started in business I received two kinds of advice from people who seemed to genuinely want to help me succeed; there was the good and the not-so-good. Some of the good advice was on how to handle the money I would take in from doing sales. This may sound like a strange topic to discuss, one that we all should somehow have been born knowing, but we weren’t. Even the most experienced of shop owners can make costly mistakes when it comes to handling their money.

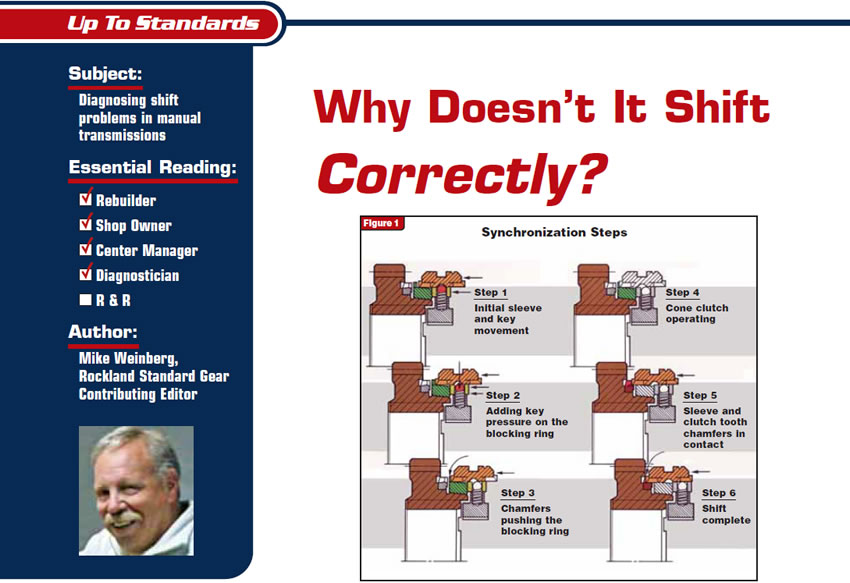

Why Doesn’t It Shift Correctly?

The first step to any diagnostic solution is to understand the theory of operation of the components involved in the problem and how they relate to each other. What is involved in making a shift with a manual transmission? The clutch set and related components (hydraulics, pilot bearing, release bearing, motor and body mounts etc.) and the transmission internal components and shift mechanism.

Myth Busters

Last month we reviewed the results of chassis dyno testing done by Sean Boyle’s students in the automatic-transmission class at Southern Illinois University. Four modified torque converters were evaluated. The testing was done on an MD-250 Mustang Chassis Dyno, and the test vehicle was a stock 2000 Dodge Durango RT equipped with a 5.9-liter gas engine and a 46RE transmission.

Make Use of Those Mystery Fixes

With the transmission industry changing almost every day, we have to stay on top of the “3 C’s” if we plan to survive. The 3 C’s, of course, are Complaint, Cause and Correction. But in the transmission business, working through the 3 C’s can leave us a little short of our goal. We can’t quit just because we have found a bad part. Once we understand that a particular part has failed, it may help us to reduce repeat failures if we can understand why it failed.