A Different Fix for an Old Problem

The problem of bore wear on torque-converter-clutch pistons has been around since lockup torque converters were born. The rotational restriction on the pistons is handled by splines, pins or fingers. But centering the pistons is generally the sole responsibility of the bore. Any out-of-balance movement of the piston will cause the piston bore to scuff against the turbine hub when it moves to apply or release the clutch. Indexing the piston to the turbine and balancing this unit helps minimize bore wear. (See the article on indexing TCC-piston damper assemblies to turbines, Transmission Digest, March 2006.)

Building a Reaming & Inspection Station

As valve bodies continue to evolve and become more complex, rebuilders are finding it increasingly necessary to have a central location for bench reaming and inspection of valve bodies. Many transmission shops have found – to their surprise – that building an inspection and reaming station can be inexpensive and that a station can be put together from many items already available in the shop.

45RFE: Mystery Code 1781

This is another one of those frustrating and mind-boggling codes that you do everything to try to get rid of but it seems to always come back. The worst part about this code is that it will not appear when the vehicle is in your shop. Unfortunately, the code is intermittent and its frequency is erratic.

How Things Work: Four-Wheel-Drive Systems

The transfer case is a very simple concept. It is basically a power divider mounted on a transmission that is capable of splitting torque produced by the engine to drive both sets of axles on the vehicle.

July 2006 Issue

Issue Summary:

After overhaul of a 4T65-E, the vehicle does not move after remaining stationary for a prolonged period.

After transmission exchange or valve-body replacement in a vehicle with a 4T40/45-E, the TCM stores code P1810 for the transmission-fluid pressure-switch assembly immediately after engine start-up.

Certain Dodge/Jeep trucks with 45RFE/545RFE transmissions may exhibit a complaint of a harsh 2-3 upshift accompanied by a clunk or shudder when accelerating, or a harsh 4-5 upshift or 5-4 downshift.

Some 1999 Ford F-Series Super Duty vehicles with the 4R100 transmission and 7.3-liter diesel may exhibit what appears to be a flare-up on either the 2-3 or 3-4 upshift.

Missing You

Have you ever built a unit that went out running absolutely fantastic but came back with a problem only a month or two later? Maybe you were so good to that transmission that it was missing you and wanted to come back for a visit!

4R100: Repeated Converter Failure

In this lesson we will hear of a 4R100 in a 2000 7.3-liter diesel with repeated (four times) converter failures.

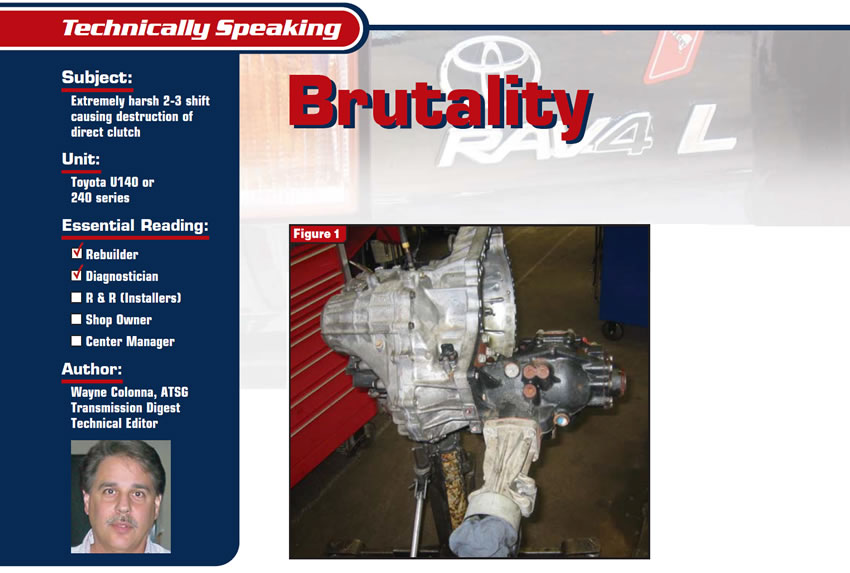

Brutality

Toyota vehicles using either the U140 or 240 series transmissions (see Figure 1) are known to produce a brutal 2-3 shift, to the point that the direct clutch disintegrates and spreads debris into the system, taking out the drum and cover (see Figure 2).

What Went Wrong and Why: Root-Cause Failure Analysis

Comebacks will have many causes, including some that are beyond the shop’s control – such as human error and new parts that are defective right out of the box. If a shop is not running at a comeback rate of 5% or less, it will be dangerously close to failing as a business. This is because there are two costs involved in repairing a comeback: The first is the parts and labor invested for free in honoring your warranty; the second loss is called “lost-opportunity costs,” which reflect the fact that when working on a comeback you cannot be working on a paying job. We will examine here how to make a comeback into a positive experience even though it costs money, and how to cut your losses and protect yourself from further wasted labor and parts dollars.

Getting Your Cores Back

When torque converters first transitioned from the early bolt-together units to the welded/sealed units of the present day, transmission shops were faced with a new challenge. Most customers weren’t willing to pay for a new OEM converter on top of the cost of a transmission overhaul. The only alternative available at that time – reusing the customer’s original converter – seldom saved the customer or the transmission shop any money. More often than not, reusing the original converter created new problems when contamination from the original failure entered the newly overhauled transmission.

June 2006 Issue

In This Issue

Shift Groups: Principles of Operation

Assembly Difficulties: K3 Hub and Rear Sun Gear

Hiring a Good Service Writer or Shop Manager

Many owners believe that they can save a $50,000-a-year salary if they do the selling themselves, but if they aren’t any good at it or their hearts aren’t in it they might be throwing away $150,000 in additional profits to try to save $50,000. I can understand the concept of running lean and mean if the phones aren’t ringing much, in which case a lot more promotional work needs to be done, but if they are ringing and the work isn’t being sold because of an owner whose sales techniques are questionable at best, not having a manager is a major mistake in judgment.