Consolidated Vehicle Converters, Inc. (CVC)

Consolidated Vehicle Converters, Inc. (CVC) founder Julie Maynard-Turner says she didn’t set out to create the large-scale torque converter remanufacturing operation that the company has become. She remembers her start-up in April of 1996 with herself & one employee. Soon afterwards, her sister Marcia Maynard-Prugh joined the effort, to be followed later by her brother-in-law Tim Prugh. After a brief absence from the industry her father, John Maynard, a pioneer in the converter rebuilding industry, also came on board. “At age 84 he still comes into the plant every day and is a vital part of our management team and we’ve all adopted his work ethics,” she recalls.

Julie says that the time has quickly passed while the management team seems to always be focused on the next phase of increasing capacity to keep up with expanding demand. This year, as CVC marks its 20th anniversary, she observes a history of remarkable growth and expansion while simultaneously looking to a future of opportunities to continue the growth and further enhance the product line and the CVC brand.

Tim has spent quite a bit of his time during the past year dealing with a challenge that comes from the pronounced increase in weight of converters being processed at the company’s facility near Dayton, Ohio. The introduction of billet front covers to the aftermarket has been a large contributor to this increased weight. Prugh also mentions he learned recently that a new torque converter Ford is introducing for use with 10-speed transmissions weighs in at 98 pounds.

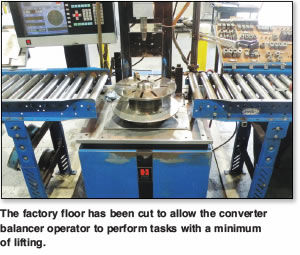

“When you combine the number of units that we need to produce for our customers to the additional weight of these units, you’ve created a situation whereby we have to consider our employees’ health, Prugh explains. “I’m looking for alternative ways to further our ongoing employee health initiative.

For example, we recently added multiple air-cleaning devices and equipment to our plant,” Prugh explains. “And, by the time this article is in print our fifth lift assist device will be in place. We’re going to continue our study of these devices, when our research and testing is satisfactorily completed, we plan to be adding more. Along with the production-line weight restrictions, we also experience a logistics issue: Heavier converters can create an overloading issue for our private delivery fleet. This weight issue along with increased demand has created additional deliveries to our scheduled 69 stops per month.

This challenging situation demanded that we add another semi-tractor, driver and the addition of two more 48-foot trailers earlier in the year.”

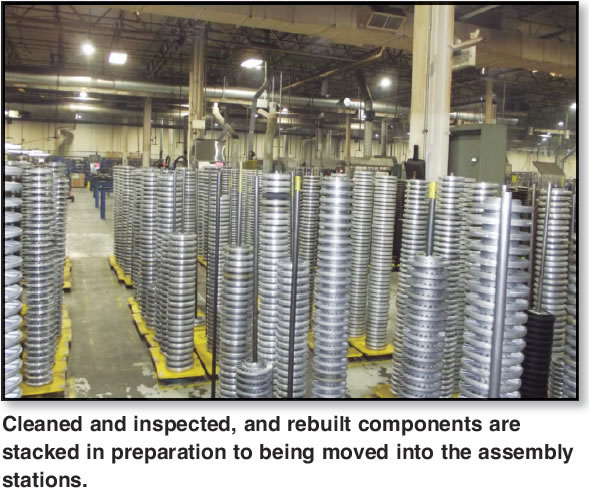

The family says that great progress has been made during the company’s 2oth anniversary year, perhaps the most important of which was John’s layout and completion of a fifth assembly line, that will allow the company to move Special Builds, R&R’s and other low volume units from Assembly Line #4 allowing that line to increase its daily output. CVC is investigating a building addition to expand storage of finished goods and raw core inventories.

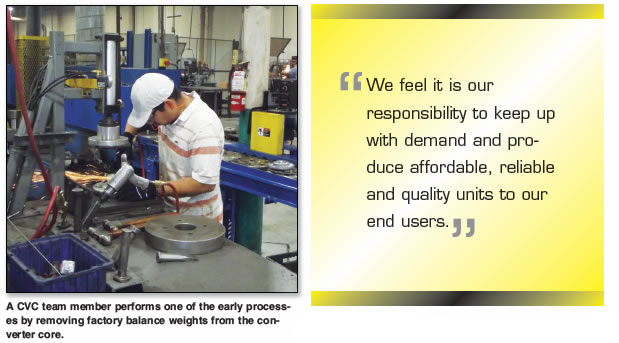

Prugh continues by saying, “Like everyone in the converter rebuilding industry, we are concerned by the introduction of captive clutches converters. In these units, clutches are either welded or riveted to the front cover. It’s not possible to remove the component and replace it on a fast-paced assembly line. These components must be removed precisely, rebuilt or replaced then meticulously refastened to the cover maintaining critical clutch clearance. CVC has cross-trained multiple team members to properly rebuild these units.”

Referring to Transmission Digest’s estimate that 95% of retail transmission jobs entail 60 transmission models. Marcia Prugh says “Where there are 60 transmissions, there will be multiple engine options; therefore, we could encounter 120-240 different converter builds. “So with multiple applications for converters that are visibly identical, it becomes ever more important to be very precise when ordering a remanufactured converter. We provide a catalog and monthly updates, along with new product bulletins complete with photographs. We maintain and provide the latest information aimed to keep everyone informed amid a complex and ever-changing marketplace.”

Julie explains that equal precision is required during rebuild operations that must consider very minor parts differences that make major operational differences in modern converters. “In light of these rapid changes, the work we perform now has to take into account even slight changes from unit to unit. Now we need to be ultra-precise in converter replacements.”

Tim recalls, “Jim Hall, who founded Dacco, and my father-in-law, Mamco founder John Maynard, often talked about how steep the learning curve was in the early days of converter remanufacturing. They had nothing like the sophisticated machinery and processes that we use today and yet the transmission industry required torque converters. At CVC, we continue to follow in their footsteps, do the best we can to supply quality converters. Believe me when I say, the learning curve is still very steep!”

Prugh sees, very much like those early days, that the requirements of learning to remanufacture, particularly given new technologies with incredibly tight tolerances, presents challenges to every remanufacturer.

“To our credit,” he adds, “we have identified almost everything that is out there today; not only every unit but every version of every unit. And, in each case, we have developed ways to rebuild them properly. The level of customization necessary on so many of these late-model units makes them time consuming and expensive to rebuild. And that’s something that the entire industry faces. We feel it is our responsibility to keep up with demand and produce affordable, reliable and quality units to our end users. Take the customization and add ever-tighter tolerances, and it’s easy to see why the days of a generic inexpensive converter are behind us. And, with converter technology evolving, we have built in additional measurements and tests to make sure that every unit is up to spec at every step of the remanufacturing process.”

Julie observes that customer satisfaction with the dependable, high-quality torque converter that CVC provides on a day-in and day-out basis is something in which the entire company takes great pride. “We recently hosted all branch managers of Whatever it Takes Transmission Parts (WIT) along with regional managers and associates for a plant tour and educational class, followed by a question and answer session. Many of those people had never visited our facility before. From the comments afterward, the following days’ emails and the phone calls we received, they were indeed impressed with the skill and work that goes into our processes. We also received comments after the visit, expressing appreciation for our attention to detail and commitment to quality from these people who are a link between our products and the builders in transmission shops.”

Julie and her sister, Marcia, realize that at times they are so focused on the problems and challenges of the converter business to the point that they forget what has been and is being accomplished. “Nothing in the world is better than to receive the positive comments, whether it be correspondence here at the plant, an electronic communication or in person at the many seminars we attend. Those are the kind of pick-me-ups that everybody needs once in a while!,” Julie observes.

Tim concludes saying “Every single challenge we talk about is a good problem to have. Operating a healthy, complex and growing business creates these types of situations – challenging yes, but much better than the alternative!”