Technically Speaking

- Author: Mike Riley

- Subject Matter: Reprogramming

- Issue: Options

There is more than one way to skin a computer

There was a time, long ago, when the owner of a vehicle would experience a transmission problem and roll into a repair facility to have it addressed. The issue would be diagnosed, the offending components would be repaired or replaced, and once done final adjustments would be made either before or after a thorough road test. Fine tuning was limited to the adjustment of a throttle rod or cable, turning a screw a couple of times on a modulator, or changing a spring on a governor. So much for the good old days!

Due to the real or perceived need to increase fuel economy and decrease emissions output the dreaded computer started to rear its ugly head. At first, the CPU was limited in use to a couple of engine functions that would supposedly address those performance concerns. Only after increased demands by the EPA and a substantial amount of trial and error by vehicle manufacturers did the fuel economy landscape really start to change. Back then, system diagnostics was not too difficult and more often than not, a simple sensor or actuator replacement would rectify the problem. If the CPU happened to be defective it was not a big thing to slap on another one and cut the vehicle loose.

As time went on the chorus of control modules was increased to address a variety of different functions i.e. (BCM, ECM, EBCM, PCM, TCM, etc). As each module was added to a vehicle, so to was the complexity to deal with them, especially when it came to diagnosis and replacement. Beyond the repair criteria was the question of OEM tweaks (updates) and how best to insert them into the black boxes.

For more than two and a half decades vehicle computers have had “adaptive learn” capabilities which means that beyond the basic programming a computer will acquire information based upon drivability conditions and in turn adjust outgoing commands accordingly. The purpose of this is to provide consistent operation as a particular component continues to wear over many miles. Once a repair is made to a particular unit (engine, transmission, etc.), the controlling CPU may have to be massaged a bit in order to make everything click. Depending on vehicle model and the repairs made, getting a particular module back up to speed could be a bit challenging. Terms such as relearn, reflash, reprogram, reset shift adapts, etc., are bandied about while determining the best fine-tune approach once the repair work has been completed. The question remains which path to take to ensure success.

Relearn: Most computer-controlled vehicles will, at the very least, require a reset to the basic factory programming, once a repair has been made to a major component. For instance, a transmission could be completely rebuilt, correctly installed back into the vehicle and with the proper fluid, only to function horribly on the road test. At that point, a computer relearn (reset shift adapts) will be required to complete the job. Once done, the transmission should shift as smooth as silk.

Based upon year, make, model and the extent of the original damage, the computer relearn process could be as simple as driving the vehicle using specific apply and shifting sequences. This procedure will work in most cases; however, it may require driving the vehicle for a fair amount of miles.

A better option is to connect a scanner to the vehicle’s OBD-II connector in order to use the scanner’s program to provide the necessary settings. There are certainly instances where the scanner does not have the specific program to get the job done which in that case may require the drivability option.

Reprogram/reflash: Beyond the relatively basic relearn procedure is the issue of reprogramming a vehicle’s computer, which can be a bit more involved.

The computer may need to be programmed or reprogrammed for a couple of different reasons. For instance, a brand-new computer is basically dumb and needs programming to become smart, in order to provide even basic functions such as allowing the engine to start. Another example could be an existing computer that requires updating due to deficiencies when the vehicle was initially launched. An original and current calibration ID number can be compared to determine if the computer is up to snuff or not. Up until recently there were a couple of different ways to implement reprogramming of a computer. Fortunately, the scenario is changing.

Option one: For a long time now a repair facility has had access to the OE manufacturer via the internet. The process requires a laptop with the proper software program, a J2534 VCI (vehicle communication interface) and logging on to the vehicle manufacturer website (Figure 1). A couple of problems with this approach are cost, which varies substantially from one manufacturer to another and, at times, the difficulty in performing downloads. Certain procedures are rather cumbersome and time-consuming, which is why a battery maintainer is usually required. It is the gift that keeps on giving (for the OEM).

Option two: In many cities around the country a relatively new business has been springing up that has to do with mobile reprogramming. A mobile re-programmer will normally purchase a yearly subscription to a variety of OE manufacturers and, when contacted by a repair facility, go to that site and implement any reprogram or download necessary. There is, of course a fee to do this (usually competitive); however, the shop does not have to invest the time or the grief to do it. When using a mobile service, compare cost to the OEM directly as well as the manufacturer’s systems that they service.

Option three: In certain cases, it may make sense to have a wrecker pick up the vehicle and tow it to the local dealer or at the very least drive it there in limp mode and pay them to reprogram the computer due to either a lack of available software or the complexity that it takes to get the job done. Although an independent repair facility is usually reluctant to do this, sometimes it is the best thing to do.

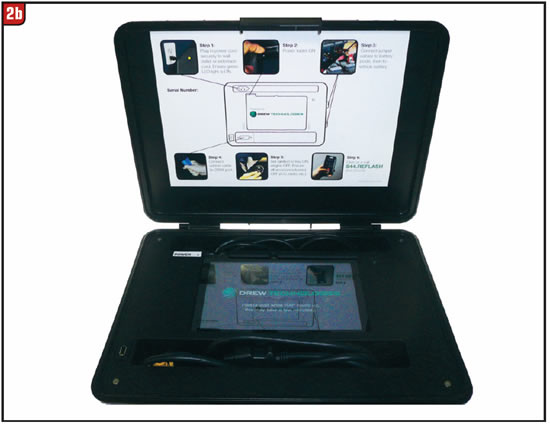

Option four: A recent development has just occurred that may make reprogramming a computer much more convenient. Drew Technologies has recently released a rather compact reprogramming kit called the RAP (remote assisted programming) that provides an easy in-shop approach to dealing with the computer reprogramming nightmare, (figures 2A, 2B). The RAP contains everything needed to provide an effortless reprogramming of the computer, including a Windows based PC, J2534 device, internet modem, battery maintainer, OE subscriptions / flash software and remote interface to Drew technicians.

Drew Technologies, working with SAE (Society of Automotive Engineers) and OE manufacturers, was on the ground floor of the development of the J2534 pass-through protocols and has continued to develop various testing capabilities for OE and the aftermarket. Today, Drew Tech and various other companies offer a wide range of pass-through devices to aid in diagnostics and programming.

The RAP is available to shops by Drew Technologies on a lease basis, meaning that Drew retains ownership of the kit. The program is based upon a “pay-as-you-go” approach and the standard fee is competitive with the other reprogramming options. The program does require a minimum of two uses (events) per month; however, if that number is not met, a small leasing fee may be applied.

After vehicle repairs are made, merely connect the RAP to the vehicle and, once contacted, Drew personnel will take it from there (Figure 3). What could be easier? Beyond programming, Drew also provides a warranty in the event that something goes south, as long as all recommended procedures were followed.

Repair facilities can contact Drew Technologies directly to obtain the specifics of the program, or transmission-repair facilities can contact Transtar Industries, which also provides the RAP to their customers. Transtar has worked closely with Drew concerning various aspects of the RAP.

Special thanks to the folks at Transtar for providing the RAP used in this article.

Currently, the RAP supports GM, Ford and Nissan reprogramming capabilities. Honda and Toyota capabilities will be available shortly with other manufacturers being added based upon need. In this era of shops having to jump through a variety of hoops, it’s nice to know that a little help is on the way.