Technically Speaking

- Author: Mike Riley, Technical Editor

- Unit: CD4E

- Issues: One-way clutch

The CD4E was launched in 1994 by Ford and Mazda in the Probe and 626, followed by the Contour/Mystique in 1995. Later on, there were other vehicles that came equipped with the CD4E, more important the 2001-up Ford Escape.

Within a relatively short time, certain deficiencies started to appear with the CD4E, the most damaging being wear issues in the valve body, which would lead to other failure problems. All of this was great for the repair industry, though, and even the OE had to step up with some improvements, which seemed to be ongoing.

Over time, however, most of the issues that plagued the earlier models seemed to have been addressed one way or another, so when a customer showed up with a 2008 Ford Escape, the issue should have been normal wear and tear and with no surprises.

The vehicle was an AWD with 102,000 miles on it and had a shifting complaint that turned out to be a first-to-third shift, no 2nd or 4th. After the external stuff was checked, the unit was pulled and peeled down to see what the issue was. Even for a 2008, it turned out to be a broken band, a problem that had been around for a long time and supposedly had been resolved. So much for perceived fixes.

Beyond the failure was another unexpected wrinkle, an upgrade. The bulk of CD4E component upgrades occurred throughout the ’90s and early Y2K, such as the forward/direct drum, servo piston, and solenoid block. For some reason, however, in the 11th hour, Ford decided to change an item that had not been too troublesome, the low OWC (one-way clutch).

From 1994 through 2006, the CD4E used a low-roller clutch (Figure 1). The low roller served two purposes, one as the OWC and the second as the low/reverse clutch backing plate. Considering what it did, the low OWC was a monster, diameter wise, and needed to be installed correctly. Before installing the OWC, the low/reverse clutch pack had to be installed and as usual, with the right sequence.

Ford also uses a specific procedure to determine the proper clearance; however, rebuilders developed their own ways to check clutch clearance. After installing the piston, install a regular steel and friction, times how many are required, ending with selective steel (pressure plate). Next, install the low/reverse waved cushion spring. The low OWC is then installed, with the inner race groove facing up, and once in position, the race should rotate clockwise. The last item is a spacer plate that fits between the OWC and snap ring (Figure 2).

Beginning in late 2006, as a phase in, Ford switched from using a low-roller clutch to a mechanical diode (ratchet clutch) similar to the 98-up 4R70W intermediate diode. Not only did this upgrade affect the OWC positioning, it also affected the low/reverse clutch stack up. The mechanical diode is a complete assembly that cannot be taken apart and must also be installed correctly. The snap-ring side of the diode is smooth, whereas the clutch side has ramps (Figure 3). In addition, there are three rubber inserts that act as anti-rattle springs to prevent noise (Figure 3A). As with the low-roller clutch, when installed correctly, the diode inner race will rotate clockwise.

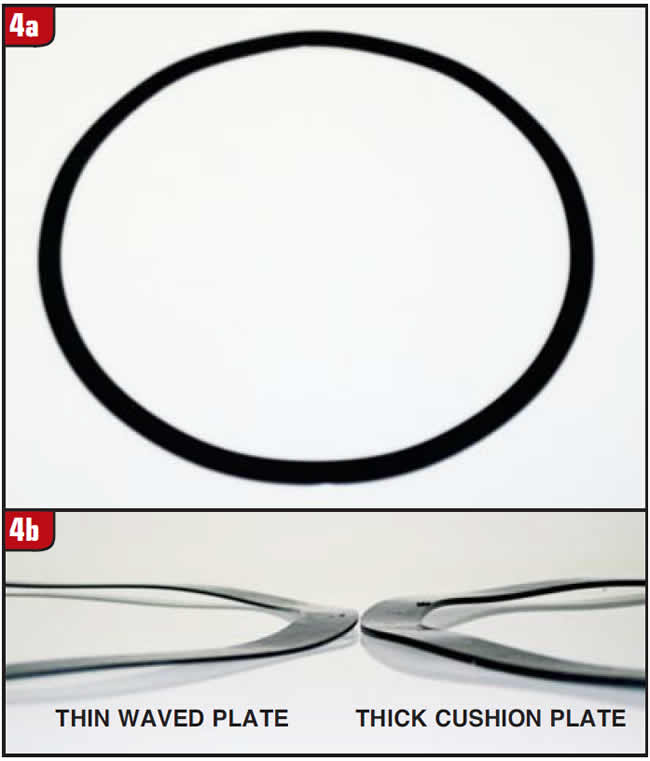

The low/reverse clutch arrangement for the diode design also changed in regard to the waved cushion spring by adding a second one. The springs are not the same, however, at least in thickness. Both springs are the same diameter (Figure 4). The actual cushion spring is thick like the roller-clutch design (Figure 4A). Ford apparently wanted a little more cushion during apply in reverse and manual low.

Not only are there two springs but the stack up changed as well. The thick spring now goes next to the low/reverse piston, followed by the alternating regular steels and frictions. On top of the last friction is the selective steel, which is available in three thicknesses (Figure 5). Identification is possible by the notches on one tab (Figure 5A). The next item in the stack up is the additional thin-waved spring that fits between the selective steel and mechanical diode. Lastly, install the diode and snap ring with the snap-ring gap in the correct position. Note there is no spacer plate as with the roller clutch design.

Goes to show, even when a transmission is on the downward slide, the OEM can always add a tweak.