R&R Tech

- Author: L.J. Porter

- Subject Matter: Diagnosis

- Unit: 48RFE

- Vehicle Applications: Dodge 2500 truck; Toyota Camry

- Issue: Noises

Cause and effect isn’t necessarily a term that you’d use every day, but it’s what brings customers to our doors for diagnosis and repair. Any technician who’s been in the business very long has seen things that are worthy of discussion and spark a bit of curiosity. This first scenario falls into that category:

A customer brought in his 1994 Toyota Camry, concerned that his brakes were hanging up as he was stopping. When I road-tested the vehicle I confirmed that there was a strange dragging feeling upon light brake application. I also noticed that when the brake pedal was applied, the “R” lamp in the PRNDL indicator illuminated even though the selector was in Drive. I also noted that the ‘tail lamp out’ warning indicator came on at the same time. The first obvious check was to take a look at the taillights themselves. I have learned over the years that you never ignore the signs right in front of you, even if you think they might be completely unrelated.

The bulb filaments appeared to be normal and intact. The fuse was OK, and I saw no issues with the sockets or wiring to them. At this point, I checked the stop-lamp switch, and it was performing as expected. Next, I checked the ground and power on the stop-lamp side of the socket – no power with the brakes applied. Now I had a confirmed system issue so I could go and search for the cause.

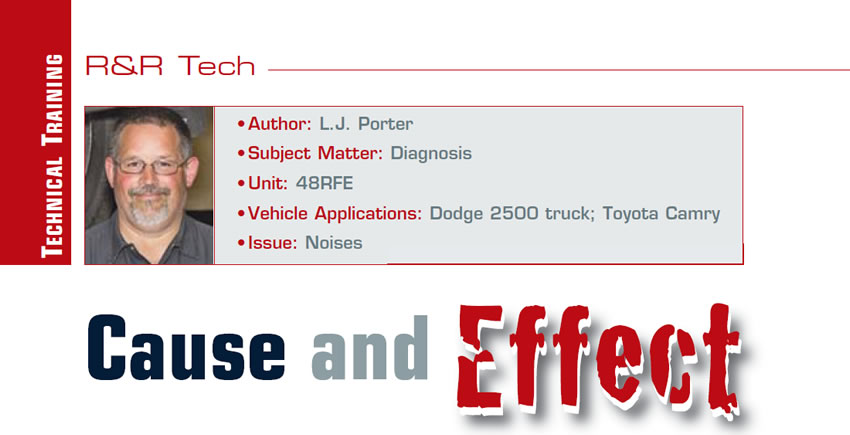

Since I had already checked most of the components in the system, I wanted to focus on the circuit itself. I pulled the trunk trim out so I could access the harness and began tracing from rear to front. At the passenger-side hinge area, I found the culprit: The harness had rubbed through from contact with the hinge. Several wires were chafed or completely broken (Figure 1).

I repaired all the wires and in doing so corrected two problems! The stop lamps now functioned properly, and the dragging feeling was corrected. How can that be? The torque-converter clutch was partially applying when the brakes were applied. This occurred because stop-lamp voltage was back-feeding into the system through the shorted wiring and applying the converter-clutch solenoid just enough to make it drag during braking. It also appears that this was causing the “R” lamp on the dash to illuminate. If the customer had ignored these symptoms, the converter clutch more than likely would have failed over time.

Switching gears (pun intended), I have an anecdote that is more in line with transmission repair. The cause is often overlooked, and more common than one may think.

This case involves a 2007 Dodge 2500 pickup with a 6.7L diesel and a 48RFE with the complaint of a noise when it was running. A generic description, indeed, but it was all we knew given what was written on the night-drop form.

After verifying that there was a metallic scraping noise from under the truck, we put the truck on a lift to see what was going on. The noise appeared to be coming from inside the bellhousing area, so we advised the customer that we would have to remove the transmission to diagnose the issue.

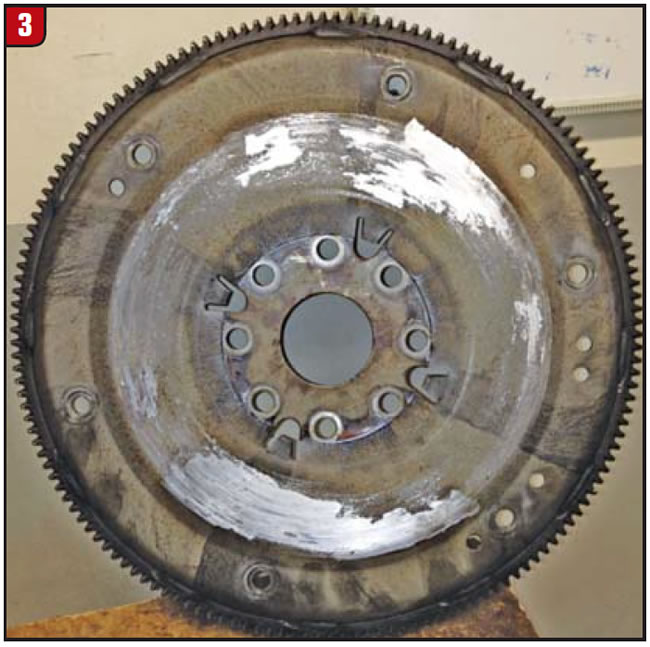

After we removed the unit, it was clear that the converter bolts had been rubbing the transmission separator plate at the back of the engine (figures 2 & 3).

Many times we can trace the cause to a bent flex plate, or worn crankshaft thrust bearings that cause excessive endplay and allow the converter to walk forward with the crankshaft and contact the separator plate.

Inspection revealed that the flex plate was cracked (Figure 4).

This was an OEM setup, and we determined that this damage was caused by the torque converter “ballooning” into an oversized state, causing contact between the flex plate and separator plate. We learned that the customer uses this vehicle for his roofing business and pulls a large, heavy trailer containing gear and supplies.

In an attempt to help protect his transmission, he bought a performance programmer that allowed him to adjust the transmission’s line pressure. Unaware of the consequences, he had set the line pressure much higher than OE. This excessive line pressure, coupled with extreme heat from the heavy loads, resulted in the ballooned converter that, in turn, damaged the flex plate.

Our cure for this issue was to install one of our heavy-duty transmissions that includes its own controller calibrated to work directly with this setup. We also installed a heavy-duty flex plate. As a side note, it is recommended that thread locker be used on the converter bolts, as these vehicles tend to shake them loose over time.

It all comes down to having the right combination for the intended use. Performance programmers can be great for adding power and performance to an otherwise stock vehicle. However, if not used by a professional, it’s easy to set things up to fail, as shown here.

L.J. Porter has been a diagnostician for Certified Transmission for more than 20 years and is an ASE-certified technician.