Sometimes a vehicle comes into the shop with a code in memory and a concern, and it is quick and easy to follow the code and find the source of the problem. But how do you know if a car is lying to you, trying to throw you off the trail with some false information? This is a question we must ask ourselves quite often in the automotive industry. The following is an example of a dishonest vehicle and how we went about catching it in its lie.

The vehicle in this story is a 2014 Dodge Ram C/V Tradesman. The van is equipped with a 3.6L V-6 engine and a 62TE transmission. This vehicle came to us after the owner had another shop install a used transmission, and upon installation it was found to be setting a code and going into limp mode. Apparently, this was the second attempt at a used transmission without success, so the customer decided to bring it to us to see if we could figure out what was going on.

Since there had been previous work done on the van, we took some extra time, looking over things like wiring, connectors, grounds and just the general quality of the installation. There were no obvious issues found with the installation process.

After our visual inspection and a fluid level and condition check, we performed an alternator and battery test. These also checked out. The next step involved hooking up the scan tool and checking for codes. This yielded both engine and transmission codes. The engine codes were P0405 (EGR Position Sensor), and P0420 (Catalyst Efficiency).

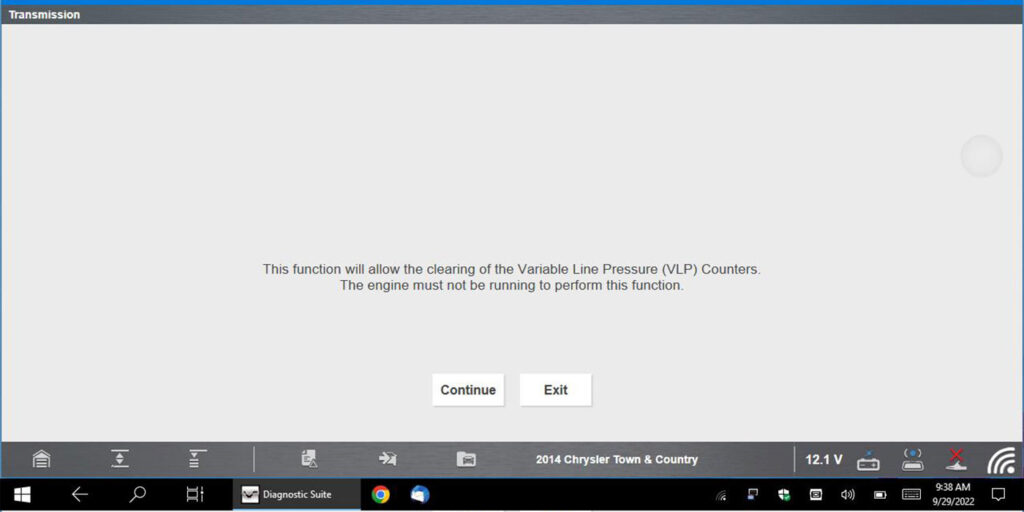

The transmission side had code P1745 (Transmission Line Pressure Too High) for too long. Upon seeing this code, while monitoring PIDs I looked at the desired vs. actual line pressure, and there was a difference between the two. I wondered if the previous shop had possibly overlooked or was just unaware of the procedure to reset the variable line pressure (VLP) counters and then doing a quick learn on the transmission. I figured it wouldn’t hurt to give it a shot.

Upon trying to perform the reset, the scan tool would not complete the procedure and instead gave an error message that the conditions were not correct. I tried it once more with the same results. What was preventing it from performing the reset? I was using our Snap-On Zeus to perform this task and have done so many times with no issues. Since I was having an issue in this case, I decided to connect the WiTech instead, and see if I had a different result. Unfortunately, I did not; I still got the same error that the conditions were not correct. There are not many conditions that need to be met in KOEO. Really all the tool says is, “The engine must not be running to perform this function.” (See Figure 1).

I did double check that the calibration was up to date using the PDF file you can download from the Chrysler Tech Authority site. It was.

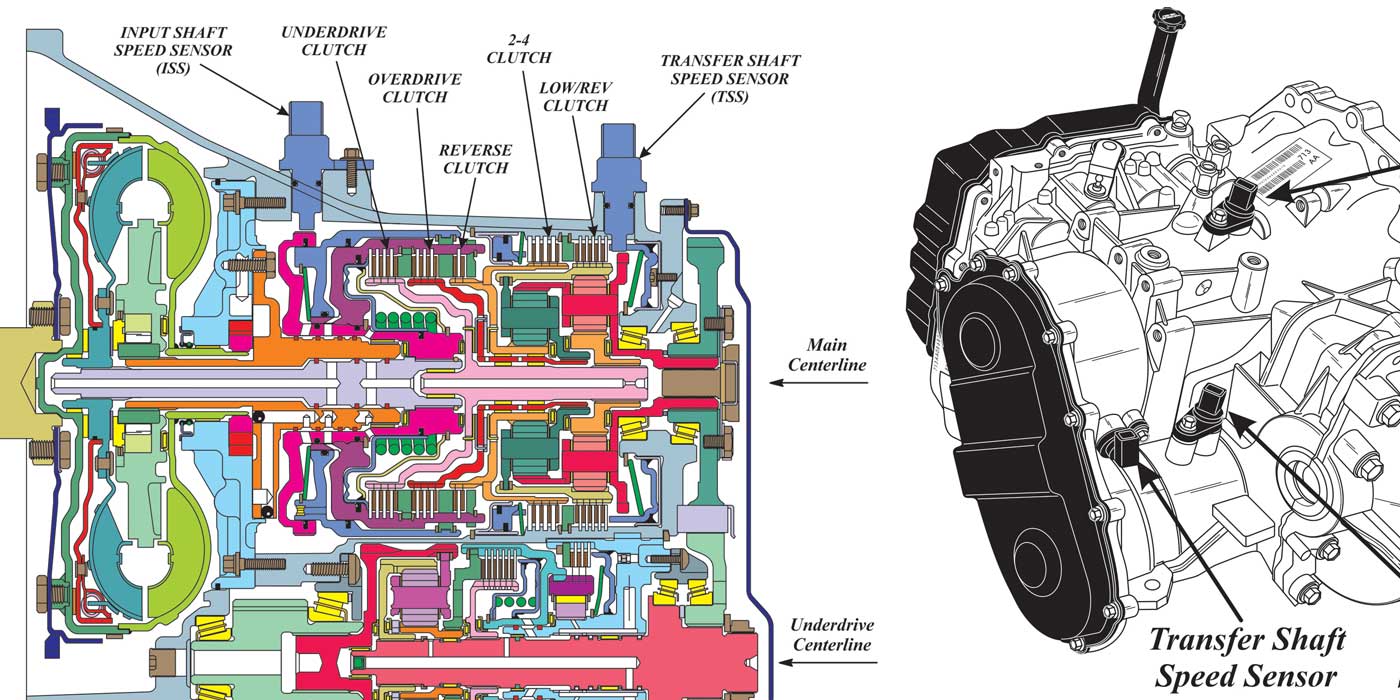

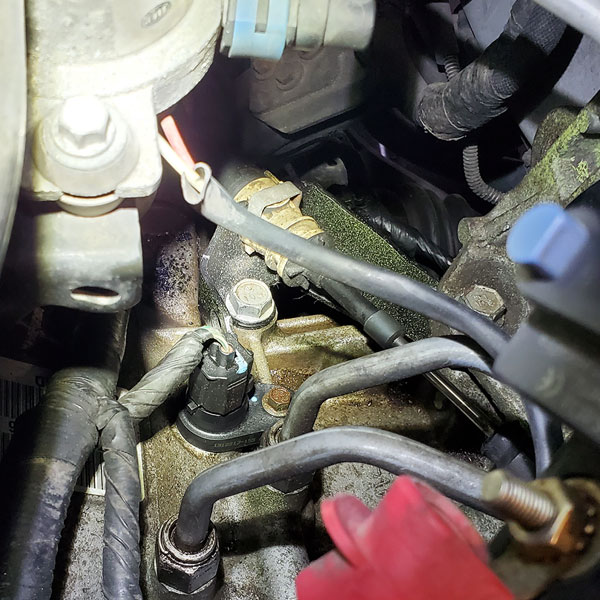

I started looking at the data while the van was running, going through all the PIDs when I noticed something missing: There was no turbine speed RPM while the engine was running, and the vehicle was in park. Interesting. There was no code for input speed sensor signal, so I had not specifically looked at that PID in the beginning. I wondered how this could play into the error I was getting, but it didn’t make sense that it could affect the procedure in KOEO since no signal is generated under that state. I went under the hood and looked at the connection to the input speed sensor. It is easy to get to as it is located on the top of the transmission. (See Figure 2).

The connector looked good, so I decided to pull the sensor out and inspect it. There was quite a bit of metal on it. (See Figure 3).

At this point I had the service writer contact the customer and get permission to order a new turbine speed sensor. The customer agreed and the sensor was ordered. Once it arrived, I installed it into the transmission, cleared the codes and started the van. I once again attempted to reset the VLP, and it reset it right away without issue. I brought up the desired and actual line pressure PIDs, and now the values correlated with each other as they should. The van was now out of limp mode, so I decided to take it for a road test. It operated flawlessly. In the end, the vehicle didn’t tell the truth about was going on (no turbine signal codes) but was instead setting a code relating to line pressure sensor.

I later found out that when the used transmissions were installed in the van by the previous shop, the sensors were transferred over from one transmission to the next, so the failed sensor just kept getting moved over to the next unit. This was the cause of the same code and symptom across the different transmissions. Since the sensor itself was not setting a code, it kept getting overlooked as they were looking for a line pressure problem per the code.

In the end a simple fix had cost a shop a lot of time and money because the vehicle was not telling the truth about the source of its problem. Not everything is as it seems. Keep interrogating those vehicles!