Up To Standards

- Author: Mike Weinberg, Contributing Editor

Bolt-on parking-brake assembly on some ZF manual transmissions requires careful handling.

Ford light-duty trucks have been equipped with ZF five- and six-speed manual transmissions since 1987. The ZF S542, S547, S547M and S650 have been used behind gas and diesel engines and are manufactured in two- and four-wheel-drive versions.

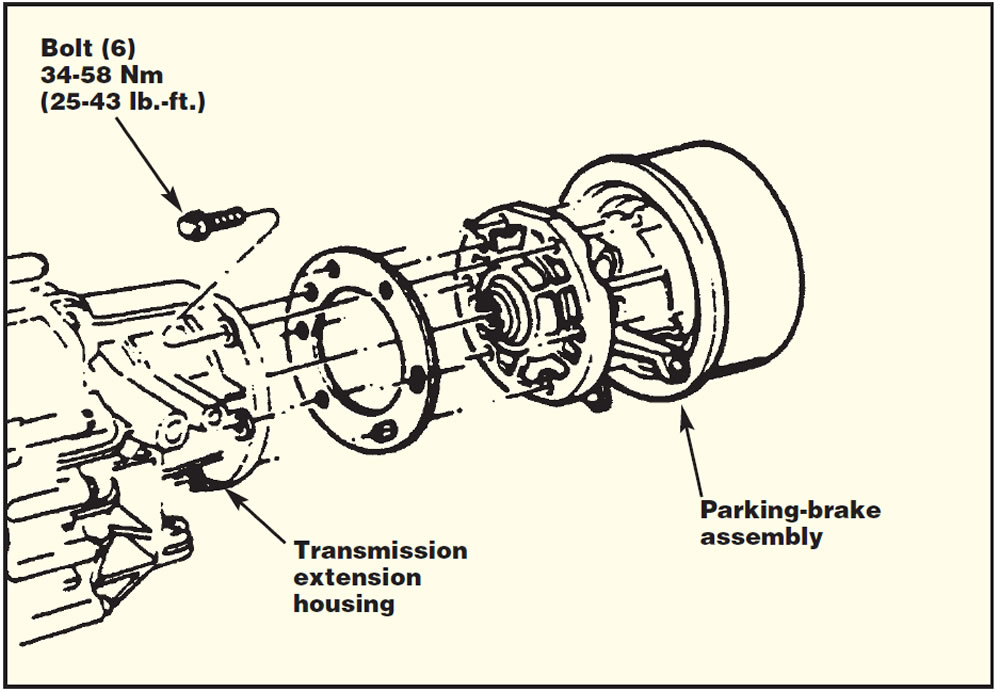

The two-wheel-drive models use a bolt-on parking-brake assembly for added safety when the vehicle is parked or for operating the engine while the vehicle is stationary, such as using a power-take-off option to work pumps or winches. The parking-brake assembly is self-contained and is actually a drive yoke coupled to a drum containing a set of outward-expanding brake shoes and a yoke to connect the driveshaft to the transmission. When the emergency or hand brake is set and adjusted properly, the brake shoes expand to hold the drum stationary and prevent the driveshaft from turning, keeping the vehicle from rolling.

The parking-brake unit can be removed as an assembly for access to the transmission for repairs, or for service of the brake components. This is where the easy part ends and the mysterious problems begin.

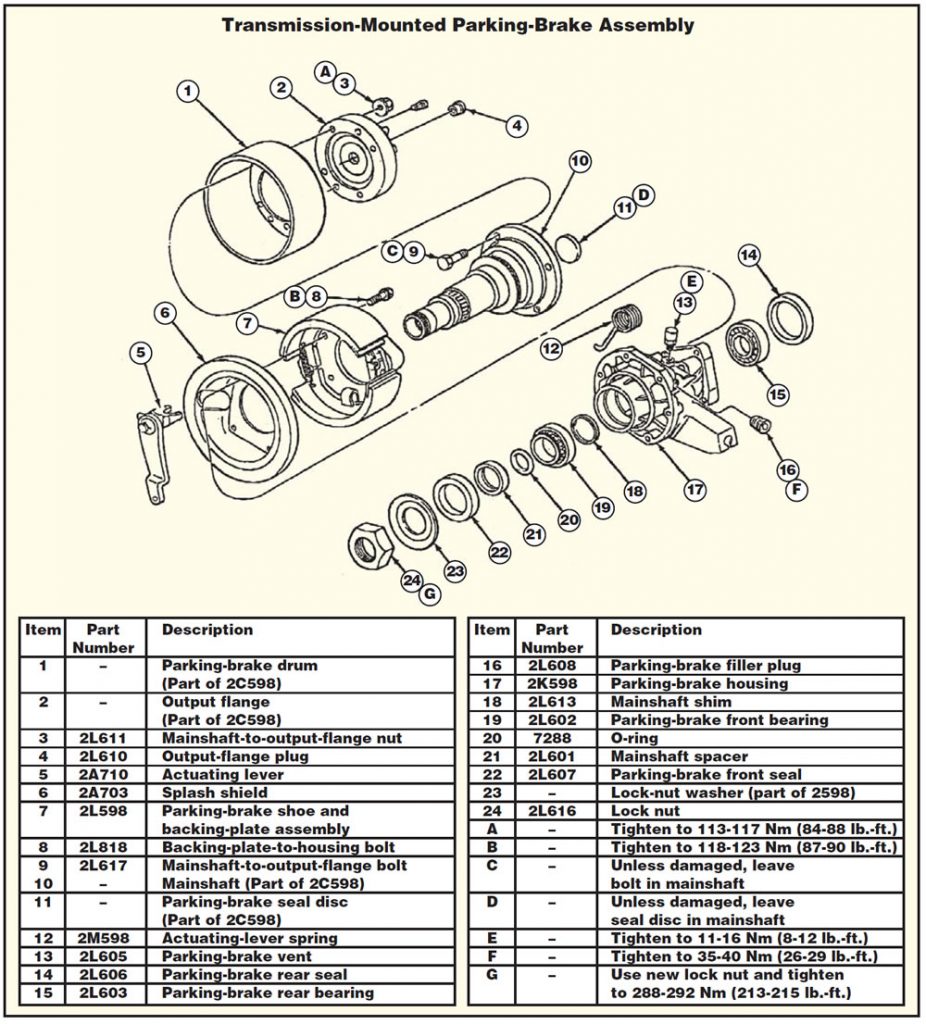

The ZF parking-brake assembly is self-sealing and uses 4.1 ounces of Mercon transmission fluid as a lubricant to keep the internal bearings lubricated and cooled. About 400,000 of these units have been produced over the years. The parking-brake assembly has a fill plug and a vent, and technicians often overlook the lubrication aspect of these units during service and repair.

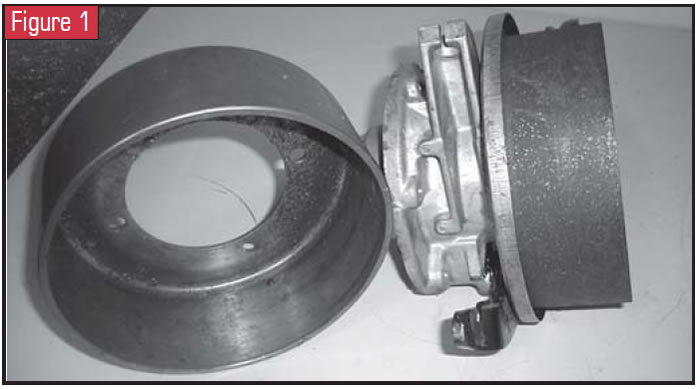

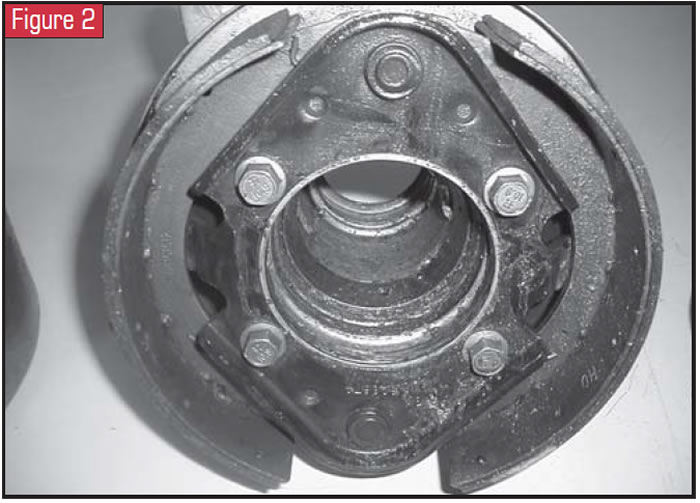

Careless handling of these assemblies can create some expensive and time-consuming comebacks. If the unit is filled with fluid and tipped over or turned upside down, the fluid will leak from the vent and contaminate the lining of the brake shoes, ruining them. If the brake assembly is installed without fluid or with insufficient fluid, the internal bearings and seals will fail in short order. Photos 1 through 5 show an assembly that was brand new and installed by the purchasing shop without being filled with oil. This damage occurred within one mile of driving, and the manufacturer would not honor the warranty on the unit because it was not filled with lubricant as specified.

Because of the extreme heat generated by the dry bearings in the assembly, the splines on the output shaft of the transmission often will twist under the driving load. This also will make the matching splines on the mainshaft of the parking-brake assembly twist in a corresponding pattern. As a result, the brake assembly is now impossible to remove from the transmission. No amount of pulling power will separate the brake assembly from the transmission output shaft, and only a torch or a plasma cutter will work to get it apart. This means that a new brake assembly (at considerable expense) will be required and the transmission will need to be removed and disassembled for replacement of the output shaft. It is very common to have these units shipped in for repairs with the brake assembly still attached because of this type of failure.

If you are replacing a clutch in a vehicle equipped with this transmission and brake assembly, be sure to handle the unit with care so it will not fall over and lose the fluid. After doing the clutch job, make sure to check the fluid in the transmission and the parking-brake assembly once it is installed before test driving.

When separating a brake assembly from the transmission to repair the transmission, make sure to keep the brake assembly upright so as not to damage the brake shoes, and check the fluid again in the brake assembly after re-installing it on the transmission and putting the transmission back in the truck.

When a customer comes in for service and a fluid change, be sure to check the brake assembly for proper lubrication level as part of the service. The only way to handle one of these parking-brake assemblies safely is to install it on the transmission before you add fluid and make sure the complete assembly does not fall over while you’re installing it into the vehicle.

Depending on the model of truck in which it is used, the brake assembly may have a speedometer drive cable. Whenever you check out one of these trucks, be sure to check the fluid level in the brake assembly and make sure that the unit is not leaking. If the leak goes unnoticed or the customer declines to make the repairs needed, the out come will be an extremely expensive repair. If the shop makes the error during the installation, it would have been better off never to have seen this job come in.

The exploded views of the parking-brake assembly and parts legends included in this article should help you better understand the internal working of this simple but expensive part.