Up to Standards

- Subject: Design and operation of transfer case

- Unit: BorgWarner 4484

- Vehicle Application: GM Hummer H2

- Essential Reading: Shop Owner, Center Manager, Rebuilder, Diagnostician, R&R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

In the current political and economic climate, the GM Hummer H2 is no longer “politically correct.” However, a lot of them have been produced and sold, and I suspect that more will follow.

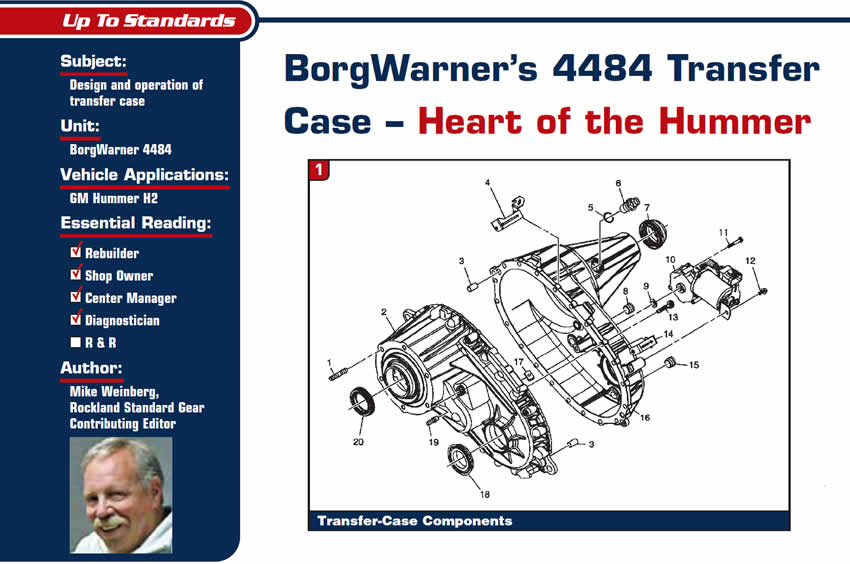

The Hummer is big and is designed for both on- and off-road use. The BorgWarner 4484 transfer case (Figure 1) provides the full-time 4WD that powers the Hummer. It’s larger than its sister unit the BW 4482, but the designs are much the same. These transfer cases are two-speed units providing full-time 4WD. These are not clutch-driven units but are an electronically shifted design using an internal planetary-type differential to achieve a 60/40 torque split rear to front. Both prop shafts are being driven continuously to provide excellent traction in all driving conditions.

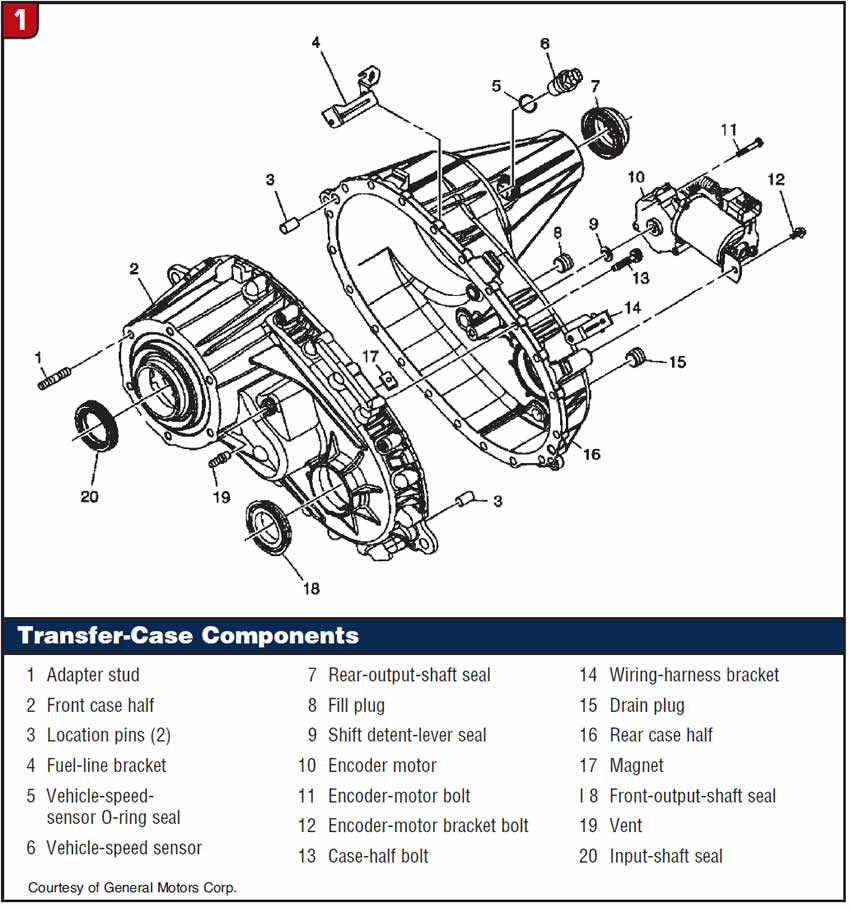

This planetary differential has two different sets of pinion teeth and two sun gears, allowing the front prop shaft to run at 40% while the rear shaft runs at 60%, full time. The front sun gear is splined to the mainshaft drive sprocket, and the rear sun gear is splined to the output shaft. Pay very careful attention to the pinion gears on the planetary differential when you are disassembling a unit. They have TIMING marks that must be aligned as shown in Figure 2, or else you will not be able to reassemble the unit.

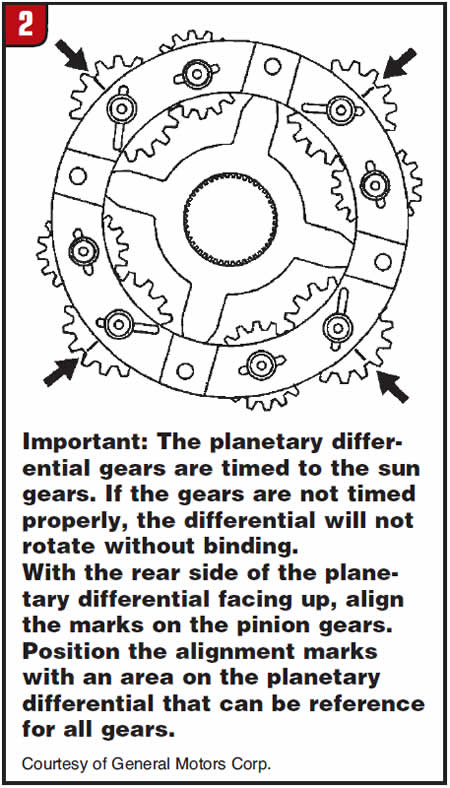

There is a planetary with sun gear and annulus gear that provides for high and low ranges (Figure 3). The low-range ratio is 2.64-1. On the dash panel is a four-button control switch that enables the driver to shift between mode and range positions.

During normal driving the unit will operate in 4W High, which allows torque to be split between the prop shafts as needed. The next range is 4W High Locked, which locks the prop shafts to a 50/50 torque split and should be used only off road on loose or slippery surfaces. The last range is 4W Low Locked, in which both prop shafts are locked in a 50/50 torque split, and the low-range planet changes the output ratio to 2.64-1. This again should be used only off road. Driving in either of the locked ranges on dry pavement will cause crow hop, tire scrub and driveline windup that will release with a bang.

Tire size and pressures must be equal to avoid these same symptoms. This is a “shift on the fly” unit with driver selection of any of the ranges possible at speed within design parameters. Low-locked range can be achieved only with the engine running, transmission in neutral and road speed under 3 mph.

There is a neutral position in this transfer case. Pushing any of the selection buttons to achieve a shift will cause the light for the desired position to flash, proving that the transfer-case control module got the message and is sending a signal to the electronic encoder/motor to shift the transfer case. When the desired shift is complete, the engaged gear will be illuminated solidly. If the shift does not occur the control module will try several more cycles before returning to the previous position, and this usually will set a 4WD-system code indicating a problem.

The encoder motor (Figure 1) is designed like other models, sending 12 volts to operate a permanent-magnet DC motor, but the encoder side, which is the electric control, never sees more than 5-volt signals on its four channels. Never put 12 volts to the encoder during a test or you will be replacing it.

If the driver wishes to shift to the neutral position the following criteria must be met: engine running, automatic transmission in neutral, road speed below 3 mph, and the transfer case in the 4WD High mode. Press and hold the 4High and 4Low Lock buttons simultaneously for 10 seconds; after the shift to neutral occurs a red neutral indicator button will light up. This was designed for towing the vehicle without the transmission output shaft rotating. I would advise against towing these vehicles in this manner. In a perfect world this should work, but it is too easy to have some of the components spline locked, and the result would be catastrophic.

An area of concern with these types of units is the construction of the cases. They are magnesium alloy, which is lighter and stiffer than aluminum. The downside is that magnesium does not like steel. By design, all steel parts that come in contact with the magnesium components are shielded. This is because of “galvanic corrosion” that occurs between dissimilar metals. The molecules tend to migrate between the two metals, either corroding each other or fusing like a weld.

Use only the original OEM case bolts, which are nylon-coated steel. Check the bolts for tears in the nylon coating, and replace any damaged ones. The bolts are self-tapping and should be run in by hand or at least started by hand. New case halves will not be threaded from the factory. The drain plugs are aluminum; do not use steel or they probably will never come back out.

The nylon-coated steel bolts all come with aluminum washers under the heads; make sure that they are there. Do not use metal-clad seals as replacements; use only OEM seals that are rubber coated on the outside. There are aluminum shims under and between all brackets and mounts; do not reinstall the unit without them. There is a gasket between the transmission extension housing and transfer case, and an OEM gasket will have writing in yellow that should face the transmission when installed. It is a very good idea to install a separate copper ground strap from the transfer case to a good ground on all electronic units.

While we are talking about magnesium, there is another important consideration for safety. Do not try to weld magnesium or weld near it. It is not easy to start magnesium burning, but when it goes up it burns with a white light brighter than the sun. It burns so hot that throwing water on it will cause the water molecules to separate into hydrogen and oxygen, resulting in a violent hydrogen explosion. If you get it burning you won’t put it out.

Another design feature found in the 4484 Hummer H2 design is an electric locking rear differential that engages in 4W Low Lock. This locks the rear, creating a spool-type differential for off-road use, only under 20 mph.

Don’t turn this kind of work away; these vehicles are big but are not hard to work on. The guy who owns one probably will not get a fair price for it in this market, and as they age they will need repairs.