Up to Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Diagnosis and Servicing Manual Clutches

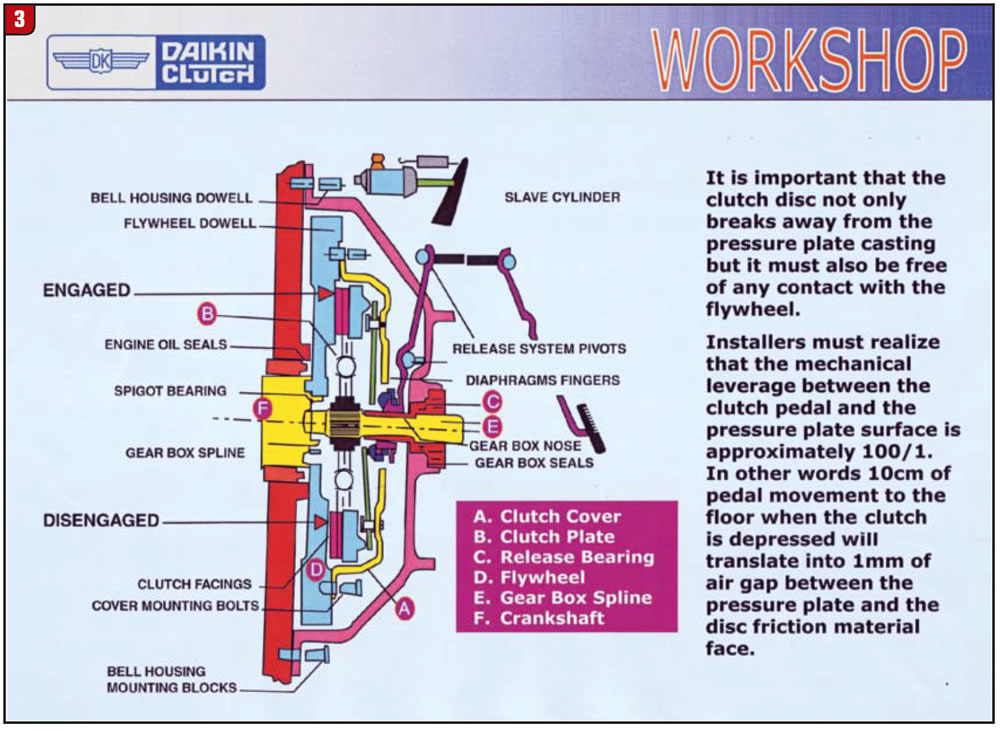

Clutch replacement has always been a steady source of business in the transmission repair shop. More and more general repair facilities are swapping clutches to add to their cash flow. There are a number of OEM quality clutch replacement sets available in the marketplace from LuK, Daikin/Exedy, Valeo, Sachs, etc. that provide OEM parts at reasonable prices. No matter how good the parts are that you are using, the installer has the responsibility for a thorough, proper installation. Anytime a manual trans is removed from the vehicle, the clutch also should be removed and inspected. A few more minutes of labor can produce added revenue from the job, decrease the chances of warranty problems, and ensure that the clutch was not the cause of the transmission failure. It is very important to make sure that the clutch is capable of transferring all of the engine torque to the transmission, and that when the clutch is disengaged there is a complete disconnect of the transmission from the engine torque. A slipping clutch will damage the clutch friction components, a clutch that does not release completely causes notchy, grinding shifts and does immediate damage to the synchronizer and speed gear components in the transmission.

Diagnosis routines start with the removal of the trans and a thorough inspection of the bellhousing, quill tube, front seals and pilot-bearing journal on the input shaft. Check the input splines for wear, rust and straightness. If the clutch disc cannot move freely back and forth, you will never achieve a proper clutch release. Check the release bearing for wear and hydraulic issues and inspect the inside of the bellhousing for worn clutch material, oil leaks and any signs of abuse, such as water contamination or sand and mud. Remove the clutch assembly and the flywheel.

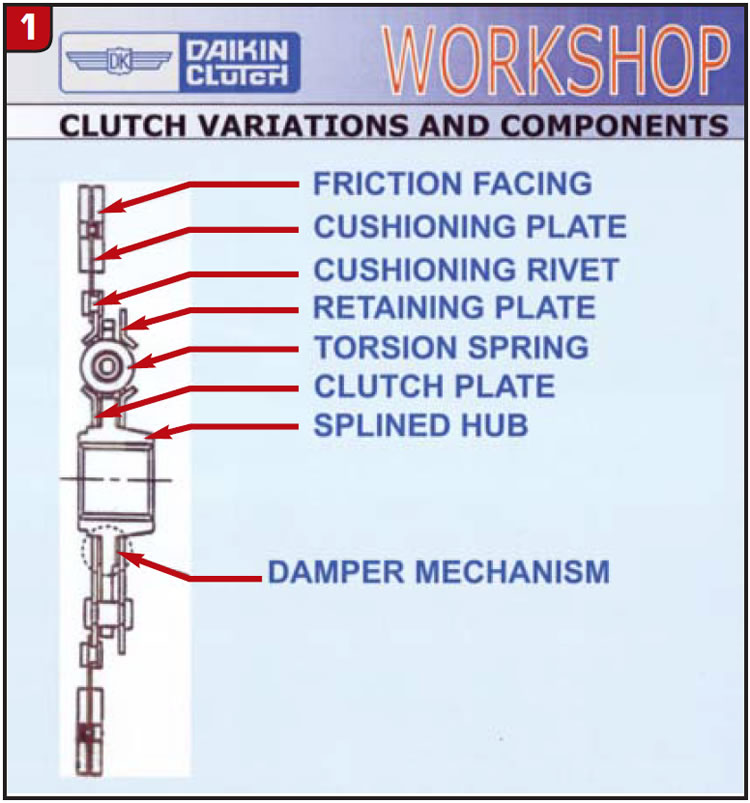

Carefully inspect the clutch disc for wear, oil contamination, broken or moved damper springs in the clutch hub, overheated material and red dust. Red dust is a sign of misalignment between the bellhousing and the block, which puts excessive runout in the disc. Make sure that the block to trans alignment dowels are in place and not worn or damaged.

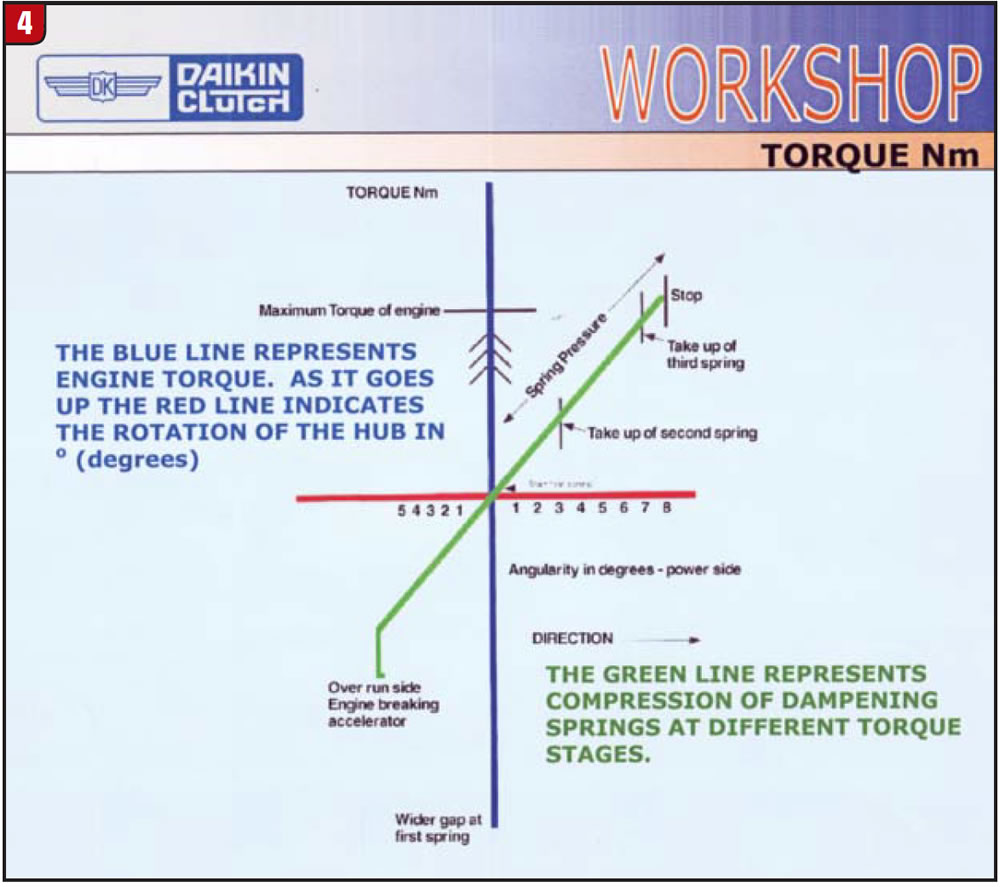

Make sure that wires or wiring clips are not trapped between the block and bellhousing – all of which cause misalignment issues. Take a good look at the disc and hub. The hub on almost stock vehicles consists of the splined hub that rides on the input shaft and a set of damper springs that allow the hub to turn during clutch engagement to soak up shock load and keep harmonic vibrations from traveling into the gear train. There are stop pins that limit the travel of the hub as it turns. Make sure these are not bent or wallowed out from excessive hub travel, which can occur due to high-rev clutch engagements.

Remove the flywheel and inspect the ring gear that engages the starter drive-gear. Look for heat spots or cracks on the flywheel surface. Anytime you are replacing a clutch you must have the flywheel resurfaced to ensure that it is completely flat and parallel to the back of the engine block, or replace the flywheel with a new one. On vehicles that use dual mass flywheels, measure the movement of the primary plate to the secondary plate to make sure that the flywheel damper springs are not collapsed or worn out.

Now on to the pilot bearing, which should always be replaced as part of the repair. If the pilot bearing is a needle bearing type install a new one to the proper depth in the crank or flywheel (depending on the design) and make sure it is lubricated. If the pilot is a bushing type DO NOT lubricate it. Those bushings are made of Oilite® bronze , which contains lubrication impregnated in the bushing material. Any lube that is added to these applications will carbon up and cause chirping noises during the clutch release. While you are at it put a good pry bar on the crankshaft and make sure that the engine thrust bearing for the crank is not worn permitting excess back-and-forth travel.

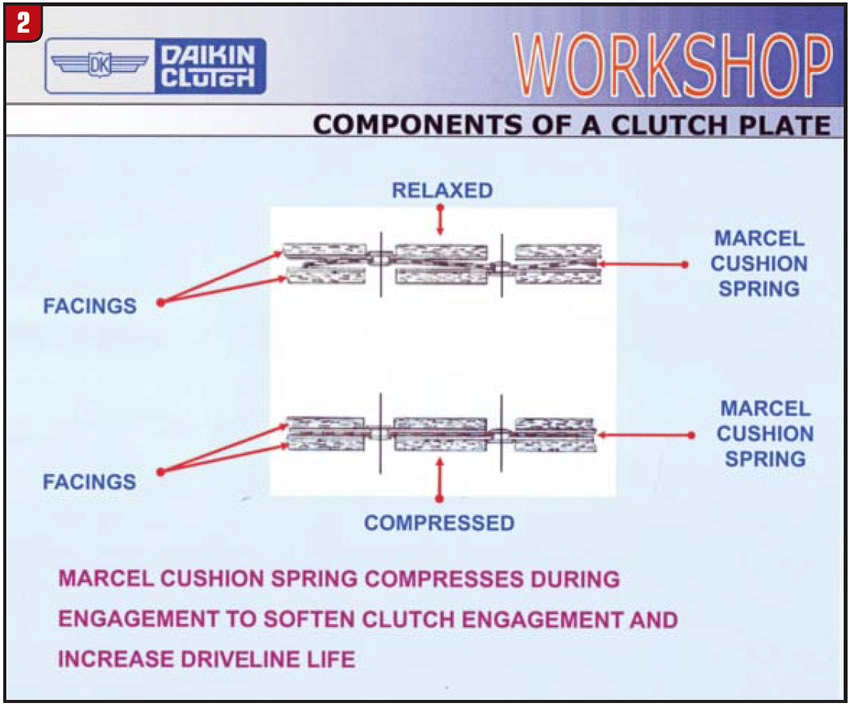

You got his far and now you are unpacking your new clutch set. Inspect the components carefully to make sure that nothing was damaged in shipping. Fit the disc onto the input splines making sure it fits and moves freely. When handling the disc, hold it from the outside edges because even the oil from your fingerprints will not do the friction material any good. Inspect the pressure plate to make sure that the cover straps were not bent or damaged in transit. Before you install the new or resurfaced flywheel take a good stone to the crank flange and the mating part of the flywheel to remove any rust, burrs or oxidation so that the flywheel will be absolutely parallel to the crank flange. Use an alignment tool to center the disc and bolt up your pressure plate, tightening the cover bolts in a star pattern to the proper torque value. A small amount of lubrication to the input shaft will prevent rust and make the disc slide smoothly. Small means small, as excess lubricant will get thrown around centrifugally and ruin the clutch friction material. Last but not least make sure that the diaphragm springs are equally flat across indicating that the clutch cover is evenly torqued.

Now, to install the transmission use a jack so that you do not hang the trans off the clutch disc which will bend the marcel plate on the disc and undo all your good work. Proper bleeding of the hydraulic system to get all of the air out starts with bleeding the system from the slave cylinder. Using a power bleeder, such as the Phoenix system, from the bottom up will ensure that the air bubbles travel the path of least resistance, which is up. Certain vehicles that have a master cylinder coming off the firewall at an angle can be hard to bleed. In these cases, jack up the rear wheels so that the master cylinder is parallel to the floor and it will be easier to get all the air out.

The manufacturers put a tremendous amount of engineering into a clutch set to make sure that it matches the engine torque level and removes any engine harmonics from transferring into the cabin or the gearbox. Be very careful with customers who wish to change from a stock clutch to something “better or high performance”. You should communicate to the driver that usually these come with trade-offs, so it does not become your problem. More aggressive clutch material usually means a harsher engagement. A non-stock setup can require higher pedal effort to use the clutch or a very aggressive clutch grab when taking off. If the customer says that they can live with that, make them put it in writing so you can say, “I told you so” and be off the hook.

There are sets that replace a dual mass flywheel with a straight one. Most of these work well because the disc has improved damping to get rid of the harmonics, but the customer still may notice a difference. If your buyer wants a more high-performance set, look at some of the options from companies like Exedy where the excess clamp load and friction ability has been engineered to perform with the same feel as the stock set, but with much greater torque capacity and durability.

Doing it right the first time equals profit. Become a great clutch hitter.

Mike Weinberg is president of Rockland Standard Gear.