Deciphering the alphabet soup of shift feel

The GM 4L60 and 4L60-E transmissions have been around since 1982, so virtually everybody in the industry is familiar with their designs and how they work. However, one thing that still generates numerous technical calls and confusion is the alphabet soup of different letter codes that are stamped on the accumulator valve. What do they

TASC Force Tips: Diagnosing 8L45 & 8L90 Shift Complaints

Sometimes attention to the smallest of items can save you big dollars.

TASC Force Tips: Hydraulics Fundamentals: Check Valves

while check valves are fairly simple in design and function, they can cause various shift issues and clutch failures when not working correctly.

Spotting the Changes to Ford 6R80 ’15-Later Valve Bodies

Ford has made some changes to the ’15-later 6R80 valve bodies that you’ll want to note to prevent any interchange and drivability problems.

Hydraulics Fundamentals: Accumulators & Shift Feel

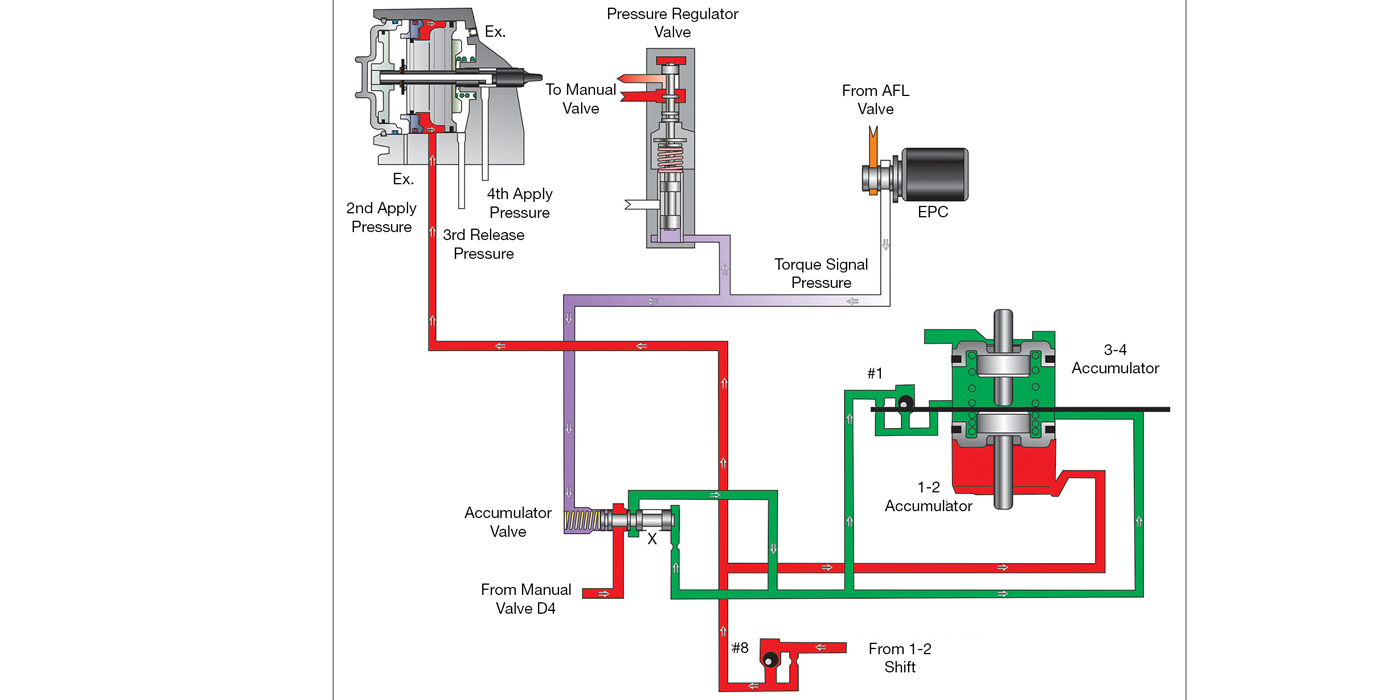

Accumulators and their circuits have been used for years as the primary method for controlling shift feel. These components are designed to modify a shift by essentially acting as a shock absorber for the fluid pressure that is applying a clutch, brake or band. Cushioning of this high pressure allows the apply component to engage gradually, instead of slamming on and rattling parts and bones alike.

‘Tween’: How to Identify ZF6HP Series Valve Body that Bridges 1st & 2nd Generation Designs

Take a ride on the memory train back to middle school. For many, this arouses feelings of a socially awkward time due to things like orthodontic braces and physical changes driven by hormones and runaway metabolism. Left behind were the childish days of elementary school, yet the yellow bus ride in the morning and afternoon signified that you hadn’t yet reached those glorious teenage years, high school and wheels of your own. By today’s popular definition, you were a “tween.”

Diagnosing Valve Bodies with Vacuum Testing

Valve and bore wear occurs when valves repeatedly stroke in a pump or valve-body casting (figures 1 & 2). This wear will eventually increase clearance beyond what is necessary to maintain a proper hydraulic seal, making it impossible for the valve to function properly. Computer adaptive strategy will attempt to compensate for poor performance in some units, but failure ultimately results, codes are set and drivability complaints occur.

Talkin’ ’Bout My Gen-eration

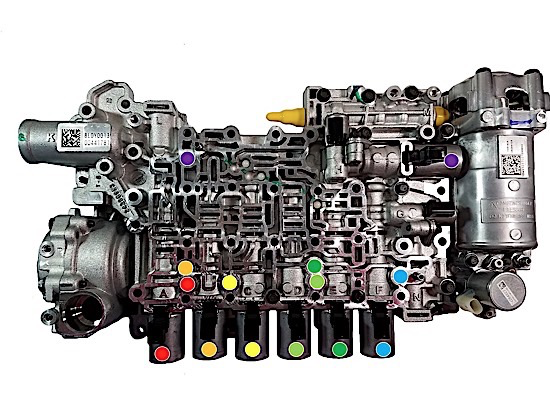

A perfect example of rapid transmission evolution is the ZF six-speeds. In these units, modifications to the mechatronic (Figure 1) were made in 2006 to increase oil flow, which reduced the duration of the shifts. So ZF6 “Generation 1” ranges from 2000 to 2005 and encompasses the ZF 6HP19/26/32 versions; ZF6 “Generation 2” ranges from 2006 through current production and refers to ZF 6HP21/28/34 units. These 19, 26, 32 and 21, 28 and 34 numbers designate sequentially larger amounts of torque capacity of the transmission.

Transmission Orifices

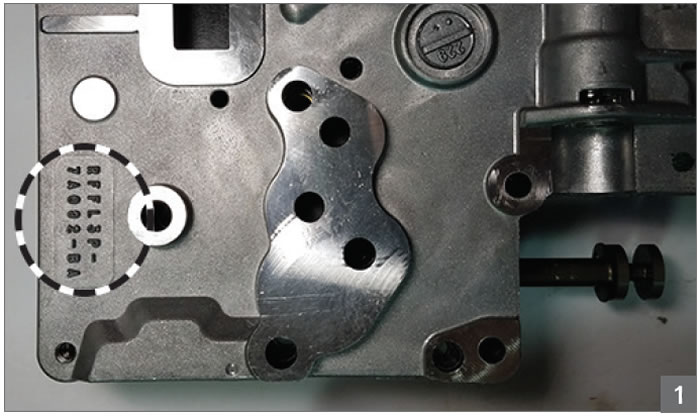

It may seem obvious initially, but when you’re talking about transmission orifices, size does matter. What may be surprising, though, is how significant a difference in vehicle performance small changes in orifice diameters can make. This becomes important when you’re considering modifications to separator-plate holes (see Figure 1) or cup-plug orifices (see Figure 2) during a rebuild.